Section 2

12

CO

2

SMO

Plus

User’s Manual Rev. 02

• Periodically check the flow sensor and tubing for excessive moisture or secretion build up.

Although the

CO

2

SMO

Plus!

automatically purges the lines, excessive moisture or secretions may

still remain.

• While using the flow sensor, a system leak, such as that caused by uncuffed endotracheal tubes or

a damaged flow sensor may significantly effect flow related readings. These include flow,

pressure, dead space, CO2production and other respiratory mechanics parameters.

• Connect the line cord to a grounded hospital-grade outlet.

CO

2

SMO

Plus!

should be connected to

the same electrical circuit as other equipment in use on the patient. Outlets of the same circuit can

be identified by the hospital’s engineering department.

•The

CO

2

SMO

Plus!

has no protection against the ingress of water.

• Do not operate

CO

2

SMO

Plus!

when it is wet due to spills or condensation.

• Do not operate

CO

2

SMO

Plus!

if it appears to have been dropped or damaged.

• Keep

CO

2

SMO

Plus!

and its accessories clean.

• Never sterilize or immerse the monitor in liquids.

• Do not sterilize or immerse sensors except as directed in this manual.

• Do not apply excessive tension to any sensor cable or pneumatic tubing.

• Do not store the monitor or sensors at temperatures less than 14°F (-10°C) or above 131°F (55°C).

• Do not operate the monitor or sensors at temperatures below 50°F (10°C) or above 104°F (40°C).

• Federal (U.S.A.) law restricts this device to sale, distribution, or use by or on the order of a

licensed medical practitioner.

• DO NOT attach an SpO2sensor distal to a blood pressure cuff. Valid data CANNOT be processed

when the cuff is inflated. Attach the sensor to the limb opposite to the site used for the blood

pressure cuff.

• Excessive moisture in the flow sensor may affect the accuracy of the flow measurement.

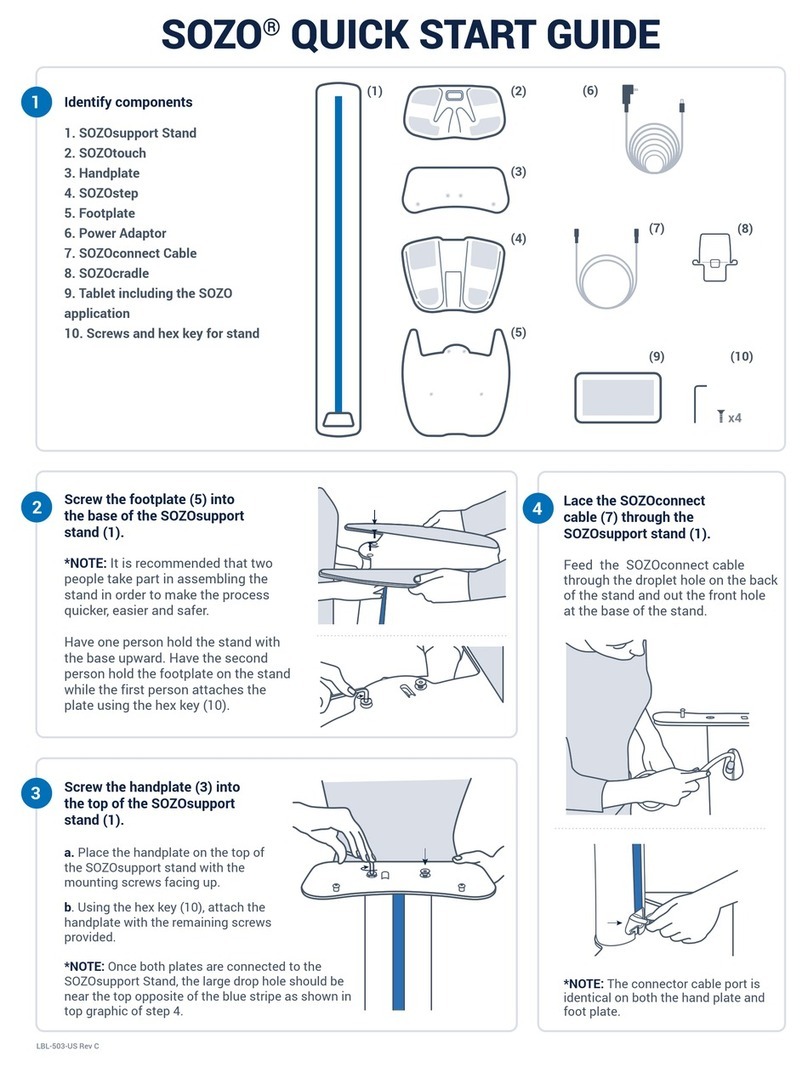

• To avoidthe effects of excessive moisture in themeasurement circuit, insert the flow sensor in the

ventilator circuit with the tubes upright (as shown by arrows). The striped tube is positioned

closest to the patient. Improper placement will result in erroneous data.

• It is recommended that the CO2/Flow sensorbe removed from the circuit whenever an aerosolized

medication is delivered. This is due to the increased viscosity of the medications which may

contaminate the sensor windows, causing the sensor to fail prematurely.

• In case of interference with our equipment or another manufacturer’s equipment, notify your

Novametrix representative.

• Components of this product and its associated accessories which have patient contact are free of

latex.

• As with all flow measuring devices, adverse conditions may affect the accuracy of the flow

measurement. See page 10 for a discussion of flow measurement.

•IfCO

2is being measured while not using a flow sensor, certain rebreathing circuits, or the

presence of artifacts such as cardiogenic oscillations, may cause

CO

2

SMO

Plus!

to react to non-

respiratory CO2fluctuations as if they were breaths. This condition affects only the numerical

displays; the capnogram display continues to provide an accurate picture of the CO2waveform.

CAUTIONS

Indicates a condition that may lead to equipment damage or malfunction.

NOTES

Indicates points of particular interest or emphasis for more efficient or convenient operation.

!