Novanta SYNRAD Pulstar p100 User manual

ENGINEERED BY SYNRAD

p100/150 Lasers

User Manual

IMPORTANT INFORMATION

Table of Contents

Important Information ......................................................................................................................................................................1

Introduction summary.......................................................................................................................................................................3

Trademark & Copywrite ....................................................................................................................................................................4

Warranty Information .......................................................................................................................................................................4

Service & Support information..........................................................................................................................................................5

Sales & Application ............................................................................................................................................................................5

Customer Service...............................................................................................................................................................................5

Technical Support ..............................................................................................................................................................................5

Reference Materials ..........................................................................................................................................................................6

Global Offices ....................................................................................................................................................................................6

Guidelines & Content ........................................................................................................................................................................6

Contents Description (p100 Laser) ....................................................................................................................................................8

Contents Description (p150 Laser) ....................................................................................................................................................8

Contents Description (Continued) .....................................................................................................................................................9

Nomenclature & Model numbers....................................................................................................................................................11

Nomenclature (Continued)..............................................................................................................................................................12

Laser Safety......................................................................................................................................................................................13

General Hazards ..............................................................................................................................................................................13

General Hazards (Continued) ..........................................................................................................................................................14

General Hazards (Continued) ..........................................................................................................................................................15

Other Hazards..................................................................................................................................................................................15

Disposal............................................................................................................................................................................................16

Thorium Safety ................................................................................................................................................................................16

Additional Laser Safety Information................................................................................................................................................17

Agency Compliance .........................................................................................................................................................................20

Center for Devices and Radiological Health (CDRH) requirements .................................................................................................20

OEM Models ....................................................................................................................................................................................21

Federal Communications Commission (FCC) Requirements ...........................................................................................................21

FCC Information to the user ............................................................................................................................................................21

FCC caution to the user ...................................................................................................................................................................22

European Union (EU) requirements RoHS compliance ...................................................................................................................22

Laser Safety Standards ....................................................................................................................................................................22

Electromagnetic Interference Standards.........................................................................................................................................22

Technical overview ..........................................................................................................................................................................27

IMPORTANT INFORMATION

Laser and Tube Design.....................................................................................................................................................................28

Optical Setup ...................................................................................................................................................................................30

Optical Isolator ................................................................................................................................................................................31

Beam Delivery..................................................................................................................................................................................32

Focusing Optics................................................................................................................................................................................32

RF Power Supply ..............................................................................................................................................................................37

Control Signals .................................................................................................................................................................................37

Operation Modes.............................................................................................................................................................................38

User I/O Connection Summary ........................................................................................................................................................43

User I/O Connection Summary (Continued)....................................................................................................................................45

Input/output Signals........................................................................................................................................................................46

Sample I/O Circuits ..........................................................................................................................................................................53

DC power cables ..............................................................................................................................................................................56

Keyswitch Functions ........................................................................................................................................................................57

Shutter Functions ............................................................................................................................................................................58

Remote Interlock Functions.............................................................................................................................................................58

Figure 3-25 p150 outline and mounting. (optional feet Synrad Part#250-20440-01)..........................................................................67

Maintenance and Troubleshooting .................................................................................................................................................68

Disabling the p100/p150 laser.........................................................................................................................................................68

Daily inspections..............................................................................................................................................................................69

Storage/ Shipping ............................................................................................................................................................................69

Cleaning optical components ..........................................................................................................................................................70

Operational flow chart.....................................................................................................................................................................73

Status LEDs ......................................................................................................................................................................................74

Laser Fault Indications .....................................................................................................................................................................76

DC Pre-Charge fault .........................................................................................................................................................................77

No-Strike fault..................................................................................................................................................................................78

Frequency Limit Fault ......................................................................................................................................................................78

Duty Cycle/Pulse Width Limit Fault .................................................................................................................................................78

Cleaning Optical Components .........................................................................................................................................................79

Index ..................................................................................................................................................................................................1

Table of Figures

Table 1-1 p100 ship kit contents: ......................................................................................................................................................9

Table 1-2 p150 ship kit contents: ......................................................................................................................................................9

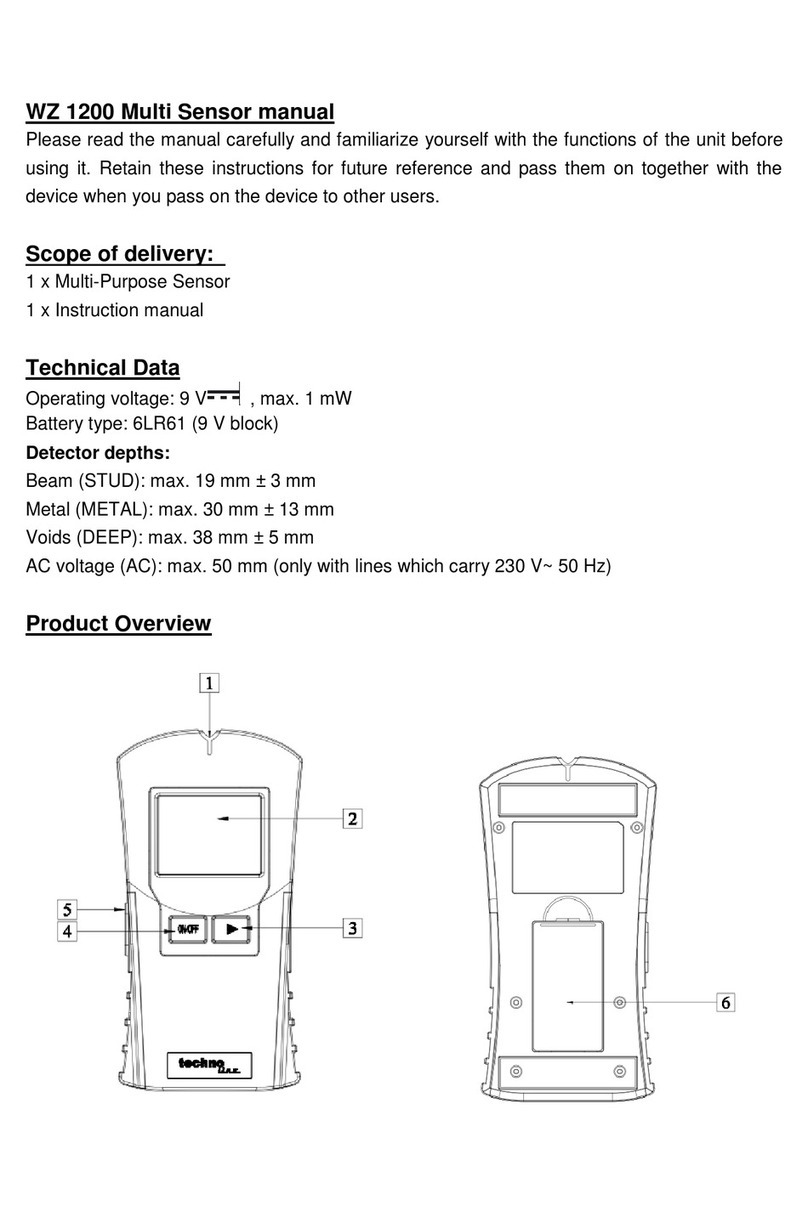

Figure 1-1 p100/150 laser ship kit contents. ...................................................................................................................................10

IMPORTANT INFORMATION

Figure 1-2 Anatomy of a model number. ........................................................................................................................................12

Figure 2-2 Always wear safety glasses or protective goggles with side shields to reduce the risk of damage to the eyes when

operating the laser. .........................................................................................................................................................................15

p100 label locations........................................................................................................................................................................18

p150 label locations ........................................................................................................................................................................19

Table 2-1 Class 4 safety features .....................................................................................................................................................23

Table 2-2 European Union Directives ..............................................................................................................................................24

Figure 2-1 p100 Declaration Document ..........................................................................................................................................25

Figure 2-2 p150 Declaration Document ..........................................................................................................................................26

Figure 3-1 Hybrid waveguide/unstable resonator design. ..............................................................................................................28

Figure 3-2 Converting 45° linear polarization to circular polarization.............................................................................................30

Table 3-1a Dew point temperatures in Fahrenheit. ........................................................................................................................34

Table 3-1a Dew point temperatures in Celsius or Centigrade.........................................................................................................35

Table 3-2 Gas purge specifications. .................................................................................................................................................36

Table 3-3 p100/150 water flow rate................................................................................................................................................36

Table 3-4 Assist gas purity specifications. .......................................................................................................................................37

Figure 3-3 PWM command signal wave form..................................................................................................................................39

Figure 3-4 Typical power curve........................................................................................................................................................40

Figure 3-5 p100 pulse profile – 37.5% duty cycle at 625 Hz............................................................................................................40

Figure 3-6 p150 pulse profile – 37.5% duty cycle at 10 kHz. ...........................................................................................................41

Figure 3-7 p100 pulse profile – 37.5% duty cycle at 5 kHz. .............................................................................................................42

Figure 3-8 p150 pulse profile – 37.5% duty cycle at 1 kHz. .............................................................................................................42

Table 3-5 PWM Command signal specifications..............................................................................................................................42

Figure 3-9 User I/O connector pinouts. ...........................................................................................................................................44

Table 3-6 User I/O pin descriptions. ................................................................................................................................................45

Figure 3-10 Auxiliary DC power diagram. ........................................................................................................................................47

Table 3-7 User I/O pin descriptions continued................................................................................................................................47

Figure 3-11 Quick Start Plug wiring diagram. ..................................................................................................................................49

Figure 3-12 Input equivalent schematic. .........................................................................................................................................50

Table 3-8 Input circuit specifications...............................................................................................................................................50

Figure 3-13 Output equivalent schematic. ......................................................................................................................................52

Table 3-9 Output circuit specifications............................................................................................................................................52

Figure 3-14 Customer-supplied interlock. .......................................................................................................................................53

Figure 3-15 Customer-supplied interlock, negative voltage............................................................................................................53

Figure 3-16 PLC driven interlock signal............................................................................................................................................54

Figure 3-17 Multiple PLC driven inputs. ..........................................................................................................................................54

IMPORTANT INFORMATION

Figure 3-18 output driving warning lamp ........................................................................................................................................55

Figure 3-19 output driving relay. .....................................................................................................................................................55

Figure 3-20 output driving PLC input module..................................................................................................................................56

Table 3-10 p100 general specifications. ..........................................................................................................................................59

Figure 3-21 p100/150 outline & mounting drawings pg. 1 of 2. .....................................................................................................61

Figure 3-22 p100 outline and mounting drawings pg. 2 of 2...........................................................................................................64

Figure 3-23 p100/150 packaging instructions .................................................................................................................................65

Figure 3-24 p150 outline and mounting. ........................................................................................................................................66

Table 4-1 Required cleaning materials. ...........................................................................................................................................71

Figure 4-1 p100/150 operational flowchart. ...................................................................................................................................73

Table 4-2 p100, p150 Input/output & LED Status Signals................................................................................................................74

IMPORTANT INFORMATION PAGE |1

Important Information

For your protection, carefully read these instructions before installing and operating the scan

head.

Retain these instructions for future reference.

Novanta reserves the right to update this user manual at any time without prior notification.

If product ownership changes, this manual should accompany the product.

Safety Symbols

DANGER:Indicates a hazardous situation which, if not avoided, will result in serious injury or death.

Its use should be limited to the most extreme situations.

WARNING: Indicates a hazardous situation which, if not avoided, could result in serious injury or

death.

CAUTION: Indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

Important: Indicates information considered important but not directly hazard related (e.g.,

security, hygiene, or equipment or property damage).

Safety Labels

DANGER:Laser radiation can cause severe retinal and corneal burns, burns on the skin, and may

pose a fire risk. To avoid injury and reduce risk of fire, please follow the control measures and

safety guidelines provided by the laser’s manufacturer, and those established by your Laser

Safety Officer (LSO), Radiation Safety Officer (RSO), or safety department of your business or

institution.

ESD Warning

MOVIA scan heads are electrostatic discharge-sensitive devices (ESD). The equipment should

remain sealed until the user is located at a proper static control station; improper handling could

cause damage to these electronics.

A proper static control station should include:

A soft grounded conductive tabletop or grounded conductive mat on the tabletop.

A grounded wrist strap with the appropriate (1 MΩ) series resistor connected to the tabletop mat

and ground.

An adequate earth ground connection, such as a water pipe or AC ground.

Conductive bags, trays, totes, racks, or other storage.

Properly grounded power tools.

Personnel handling ESD items should wear ESD protective garments and ground straps.

Important: Equipment returned to the factory must be shipped in anti-static packaging.

IMPORTANT INFORMATION PAGE |2

Important: Customers assume all responsibility for maintaining a laser-safe working environment.

Original equipment manufacturer (OEM) customers assume all responsibility for CDRH (Center

for Devices and Radiological Health) certification.

Customer Support

Before contacting Novanta for assistance, review appropriate sections in the manual that may

answer your questions.

After consulting this manual, please contact one of our worldwide offices between 9 AM and 5 PM

local time.

Americas, Asia Pacific

Novanta Headquarters, Bedford, USA

Phone: +1-781-266-5700

Email: photonics@novanta.com

Europe, Middle East, Africa

Novanta Europe GmbH, Wackersdorf, Germany

Phone: +49 9431 7984-0

Email: photonics@novanta.com

Milan, Italy

Phone: +39-039-793-710

Email: photonics@novanta.com

China

Novanta Sales & Service Office, Shenzhen, China

Phone: +86-755-8280-5395

Novanta Sales & Service Office, Suzhou, China

Phone: +86-512-6283-7080

Email: photonics.china@novanta.com

Japan

Novanta Service & Sales Office, Tokyo, Japan

Phone: +81-3-5753-2460

Email: photonics.japan@novanta.com

INTRODUCTION SUMMARY PAGE |3

Introduction summary

p100/150 Trademark, copyright, contact (service & support) information &

Nomenclature

Important Notes:

•This Operation Manual explains operation activities related to p100/150 lasers. If you cannot

operate the unit using the information described in this manual, contact NOVANTA®

(+1.425.349.3500) or an authorized NOVANTA Distributor.

•Lift the laser only by the mounting feet or baseplate. Do not lift or support the laser by its cooling

fittings.

•Please reference the Quick Start Guide for unpacking, mounting, and connecting.

•Failure to properly package the laser using NOVANTA shipping box and foam/cardboard inserts

as shown in Packaging Instructions may void the warranty. Customers may incur additional repair

charges due to shipping damage caused by improper packaging.

•Before beginning any maintenance or inspections of your p100/150 laser, be sure to completely

disable the laser by disconnecting the DC Power cable (or cables) from the rear of the laser.

•A risk of exposure to toxic elements may result when certain optical or beam delivery

components are damaged. In the event of damage to laser, marking head, or beam delivery

optics, contact NOVANTA, or the optics manufacturer for handling instructions.

•If you operate your laser in dirty or dusty environments, contact NOVANTA about the risks of

doing so and precautions you can take to increase the longevity of your laser, marking head, and

associated optical components.

•Remote interlock faults are not latched on OEM lasers. Clearing the fault condition re-enables the

RDY indicator and the laser will fire immediately provided the SHT indicator is lit and a PWM

Command signal is applied.

•Because exposure to CO2 laser radiation in the (9-11) µm range can inflict severe corneal injuries

and seriously burn human tissue, the OEM or System Integrator must ensure that appropriate

safeguards are in place to prevent unintended lasing.

•A risk of exposure to toxic elements may result when certain op-tical or beam delivery

components are damaged. In the event of damage to laser, marking head, or beam delivery

optics, contact NOVANTA, or the optics manufacturer for handling instructions.

•The use of the Quick Start Plug bypasses the laser’s safety inter-lock function, potentially

exposing personnel in the area to invisible infrared laser radiation. The Quick Start Plug is

intended only for initial testing and troubleshooting by qualified personnel. In normal operation,

the laser’s Remote Interlock input should be connected to the machine’s safety interlock circuitry.

TRADEMARK & COPYWRITE PAGE |4

Trademark & Copywrite

NOVANTA® is a registered trademark of NOVANTA.

All other trademarks or registered trademarks are the property of their respective owners.

© 2019 by NOVANTA.

All rights reserved.

Warranty Information

This is to certify that p100/150 lasers are guaranteed by NOVANTA® to be free of all defects in materials

and workmanship for a period of two years from the date of shipment. This warranty does not apply to

any defect caused by negligence, misuse (including environ-mental factors), accident, alteration, or

improper maintenance. This includes, but is not limited to, damage due to corrosion, condensation, or

failing to supply properly conditioned purge gas.

We request that you examine each shipment within 10 days of receipt and inform NOVANTA of any

shortage or damage. If no discrepancies are reported, NOVANTA shall assume the shipment was

delivered complete and defect-free.

If, within two years from the date of shipment, any part of the p100/150 laser should fail to operate,

contact the NOVANTA Customer Service department at 1.800.796.7231 (out-side the U.S. call

1.425.349.3500) and report the problem. When calling for support, please be prepared to provide the

date of purchase, model number and serial number of the unit, and a brief description of the problem.

When returning a unit for service, a Return Authorization (RA) number is required; this number must be

clearly marked on the outside of the shipping container in order for the unit to be properly processed. If

replacement parts are sent to you, then you are required to send the failed parts back to NOVANTA for

evaluation unless otherwise instructed.

If your p100/150 laser fails within the first 45 days after shipment, NOVANTA will pay all shipping

charges to and from NOVANTA when shipped as specified by NOVANTA Customer Service. After the

first 45 days, NOVANTA will continue to pay for the costs of shipping the re-paired unit or replacement

parts back to the customer from NOVANTA. The customer, however, will be responsible for shipping

charges incurred when sending the failed unit or parts back to NOVANTA or a NOVANTA Authorized

Distributor. In order to maintain your product warranty and to ensure the safe and efficient operation of

your p100/150 laser, only authorized NOVANTA replacement parts can be used. This warranty is void if

any parts other than those provided by NOVANTA are used.

NOVANTA and NOVANTA Authorized Distributors have the sole authority to make warranty statements

regarding NOVANTA products. NOVANTA and its Authorized Distributors neither assumes nor

authorizes any representative or other person to assume for us any other warranties in connection with

the sale, service, or shipment of our products. NOVANTA reserves the right to make changes and

improvements in the design of our products at any time without incurring any obligation to make

equivalent changes in products previously manufactured or shipped. Buyer agrees to hold NOVANTA

harmless from any and all damages, costs, and expenses relating to any claim arising from the design,

manufacture, or use of the product, or arising from a claim that such product furnished buyer by

NOVANTA, or the use thereof, infringes upon any Patent, foreign or domestic.

SERVICE & SUPPORT INFORMATION PAGE |5

Service & Support information

NOVANTA® worldwide headquarters are located north of Seattle in Mukilteo, Washington. U.S.A. Our

mailing address is:

NOVANTA 4600 Campus Place Mukilteo, WA 98275 U.S.A.

Phone us at:

1.800.796.7231

Outside the U.S.:

+1.425.349.3500

Fax:

+1.425.349.3667

E-mail:

Novanta@Novanta.com

Sales & Application

NOVANTA Regional Sales Managers work with customers to identify and develop the best CO2 laser

solution for a given application. Because they are familiar with you and your laser application, use them

as a first point of contact when questions arise. Regional Sales Managers also serve as the liaison

between you and our Applications Lab in processing material samples per your specifications. To speak

to the Regional Sales Manager in your area, call NOVANTA at 1.800.796.7231.

Customer Service

For assistance with order or delivery status, service status, or to obtain a Return Authorization (RA)

number, contact NOVANTA at 1.800.796.7231 and ask to speak to a Customer Service representative, or

you can email us by sending a message to customercare@Novanta.com.

Technical Support

NOVANTA Regional Sales Managers are able to answer many technical questions regarding the

installation, use, troubleshooting, and maintenance of our products. In some cases, they may transfer

your call to a Laser, Marking Head, or Software Support Specialist. You may also e-mail questions to the

Technical Support Group by sending your message to customercare@Novanta.com.

REFERENCE MATERIALS PAGE |6

Reference Materials

Your Regional Sales Manager can provide reference materials including Outline & Mounting drawings,

Operator’s Manuals, Technical Bulletins, and Application Newsletters. Most of these materials are also

available directly from NOVANTA web site at http://www.Novanta.com.

Global Offices

Americas, Asia Pacific

Novanta Headquarters, Bedford, USA

Phone: +1-781-266-5700

Email: photonics@novanta.com

Europe, Middle East, Africa

Novanta Europe GmbH, Wackersdorf, Germany

Phone: +49 9431 7984-0

Email: photonics@novanta.com

Milan, Italy

Phone: +39-039-793-710

Email: photonics@novanta.com

China

Novanta Sales & Service Office, Shenzhen, China

Phone: +86-755-8280-5395

Email: photonics.china@novanta.com

Novanta Sales & Service Office, Suzhou, China

Phone: +86-512-6283-7080

Email: photonics.china@novanta.com

Japan

Novanta Service & Sales Office, Tokyo, Japan

Phone: +81-3-5753-2460

Email: photonics.japan@novanta.com

Guidelines & Content

Refer to the drawings, located in the technical reference chapter, when installing and operating your

p100/150 laser. Also reference the p100/150 quick start guide located on our website.

Unpacking/Packing, Storage/Shipping, Mounting, Connecting, Cooling, Contents

•NOVANTA® recommends saving all of the laser’s original packaging. This specially designed

packaging will protect the laser from damage during storage, relocation and/or shipping.

GUIDELINES & CONTENT PAGE |7

Reference the drawings in the technical references section of this manual and the Quick Start

Guide Series at Novanta.com for re-packaging p100/150 laser.

•See the drawings located on our website Novanta.com, or in the technical reference chapter in

this operation manual mounting sections in the p100/150 Quick Start Guide located on our

website. When mounting the laser, use only one metric or SAE fastener per mounting tab on the

baseplate. Do not use any type of jackscrew arrangement as this will twist the baseplate and may

distort the tube

p100/150 nomenclature/features

CONTENTS DESCRIPTION (P100 LASER) PAGE |8

Contents Description (p100 Laser)

•Customer Communication Flier– Instead of the laser manual CD, please follow the instructions for

our latest laser manual(s) located on our website.

•p100 Pulsed Laser –The p100 laser is a compact laser generating 100 W aver-age power and

peak power greater than 390 W

•Quick Start Plug p100 – Connects to the User I/O connector. Jumpers are built into the plug to

enable the laser’s interlock circuits for initial start-up and testing.

•DC Power Cable Set (not shown) p100 – Connects 48 VDC from the DC power supply to the

p100 laser. Standard cable length is 1.8 meters (6.0 ft).

•Cooling Tubing p100– Carries cooling water from the chiller (not included) to the laser and back.

This black polyethylene tubing is 12mm O.D. by 30 feet and must be cut to length.

•Mounting Bolts & Metric Mounting Screws (not shown) p100– Three each 1/4–20 ×5/8” UNC cap

screws are provided for mounting the p100 laser to your mounting surface. Two sets of three (3)

M6x1x16mm mounting screws are included.

•Contents Description (p 100 Laser Continued)

•Gas Purge Kit p100– Provides a filtering and connection point to the laser from your facility’s gas

purge system.

•Cooling Kit p100– Adapts the laser’s straight 1/2-inch coolant fittings to 90° adapter fittings for

either 1/2-inch standard or 12-mm metric cooling tubing.

•Spare Fuses (not shown) p100– Fast-acting mini ATO-type fuses protects the p100/150 internal

circuitry.

•Final Test Report (not shown) p100– Contains data collected during the laser’s final pre-shipment

test.

Contents Description (p150 Laser)

•Customer Communication Flier– Instead of the laser manual CD, please follow the instructions for

our latest laser manual(s) located on our website.

•p150 Pulsed Laser- The p150 laser is a compact laser generating 150 W average power and peak

power greater than 600 W

•Quick Start Plug p150 – connects to the User I/O connector. Jumpers are built into the plug to

enable the laser’s interlock circuits for initial start-up and testing.

•DC Power Cable Set (not shown) p150 – connects 48 VDC from the DC power supply to the p150

laser. Standard cable length is 1.8 meters (6.0 ft).

•Cooling Tubing p150– carries cooling water from the chiller (not included) to the laser and back.

This black polyethylene tubing is 12mm O.D. by 30 feet and must be cut to length.

•Mounting Bolts & Metric Mounting Screws (not shown) p150– Three each 1/4–20 ×5/8” UNC cap

screws are provided for mounting the p150 laser to your mounting surface. Two sets of three (3)

M6x1x16mm mounting screws are included.

•Gas Purge Kit p150– provides a filtering and connection point to the laser from your facility’s gas

purge system.

•Cooling Kit p150– adapts the laser’s straight 1/2-inch coolant fittings to 90° adapter fittings for

either 1/2-inch standard or 12-mm metric cooling tubing.

•Spare Fuses (not shown) p150– fast-acting mini ATO-type fuses protects the internal circuitry.

•Final Test Report (not shown) p150– contains data collected during the laser’s final pre-shipment

test.

CONTENTS DESCRIPTION (CONTINUED) PAGE |9

Contents Description (Continued)

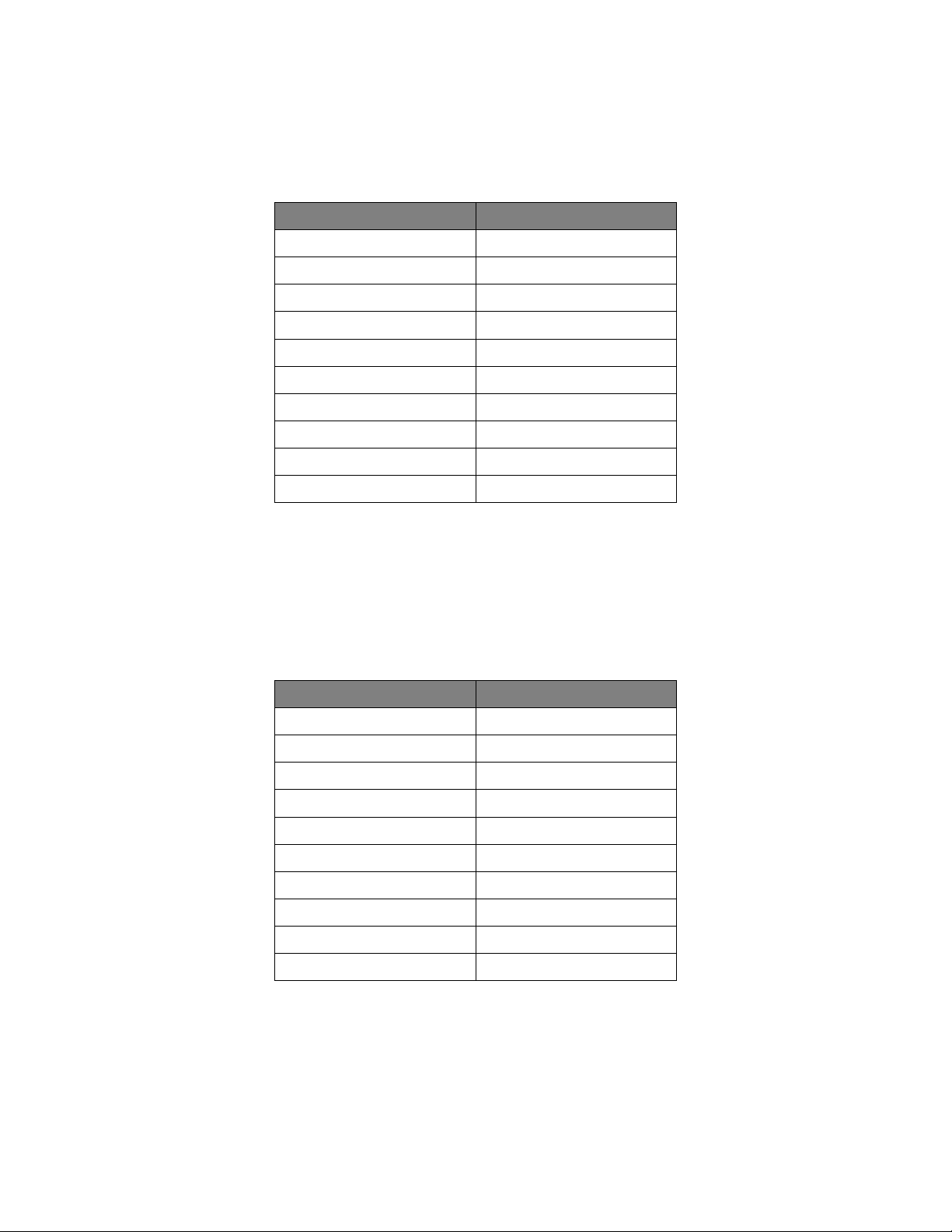

Table 1-1 p100 ship kit contents:

Shipping Box Contents Qty

p100 Pulsed Laser 1

Laser Manual url 1

Quick Start Plug 1

Cooling Tubing 1

DC Power Cable Set (not shown) 1

Mounting Bolts (not shown) 3

Gas Purge Kit 1

Cooling Kit 1

Spare Fuses (not shown) 2

Final Test Report (not shown 1

Table 1-2 p150 ship kit contents:

Shipping Box Contents Qty

p150 Pulsed Laser 1

Laser Manual url 1

Quick Start Plug 1

Cooling Tubing 1

DC Power Cable Set (not shown 1

Mounting Bolts 1

Gas Purge Kit 1

Cooling Kit 1

Spare Fuses (not shown) 2

Final Test Report (not shown) 1

CONTENTS DESCRIPTION (CONTINUED) PAGE |10

Figure 1-1 p100/150 laser ship kit contents.

NOVANTA CO2 Laser Web

Guide

Quick Start Plug

Cooling Tubing

Cooling Kit

Gas Purging Kit

NOMENCLATURE & MODEL NUMBERS PAGE |11

Nomenclature & Model numbers

The nomenclature section includes:

•p100/150 laser versions

•Model numbers

The NOVANTA® high peak power line of pulse CO2 lasers includes: p100, p150, p250 and the p400.

p100 lasers are currently available only as OEM lasers and are designed primarily for integration into

larger processing systems by the Original Equipment Manufacturer (OEM) or System Integrator who

bears the responsibility for meeting the appropriate laser safety requirements for Class 4 laser systems.

As an Original Equipment Manufacturer or (OEM) laser, the p100/150 do not comply with 21 CFR,

Subchapter J or EN 60825-14 without additional safeguards.

Designed primarily for pulse operation, the p100/150 is still controlled by a PWM Command signal;

however, the duty is limited to maximum duty cycle of 37.5% and a maximum pulse length of 600

microseconds (µs) typical. The p100/150’s pulsed RF design overdrives the laser gas, resulting in

substantially higher peak power (600W typical) than our ti-Series CW laser even though the average

power output of these two lasers is almost the same. Like our integrated ti-Series lasers, the p100/150

features a built-in RF power supply so no external RF cables are required. This compact, lightweight

design mounts easily to flatbed cutters, robotic arms, or gantry systems making integration into your

production line simple and fast.

The last three characters in the model number serve to designate the functional cate-gory, cooling

method, and model version. The functional category is indicated by either a “K” for Keyswitch or “S”

(Switch-less) for OEM models. The next letter indicates the cooling meth-od: “W” for water-cooled units,

“F” for fan-cooled units, and “A” for air-cooled lasers (the “W”

is omitted on p-Series lasers because they are all water-cooled). The last letter in the model number

indicates the current model version beginning with “B”. The OEM p100 laser is available only in an OEM

water-cooled configuration so model number PSP100SB designates a “B” version OEM water-cooled

laser.

NOMENCLATURE (CONTINUED) PAGE |12

Nomenclature (Continued)

Figure 1-2 Anatomy of a model number.

LASER SAFETY PAGE |13

Laser Safety

This section contains safety information that you will need to know prior to getting started.

•Hazard Information – includes equipment label terms and hazards, please familiarize yourself with

all definitions and their significance.

•General & Other Hazards – provides important information about the hazards and unsafe

practices that could result in death, severe injury, or product damage.

•Disposal – information on your p100/150 laser parts and/or components as they pertain to

disposal.

•Additional Safety Information – describes how to find additional information about your p100/150

laser.

•Compliance – explains in the subsections therein applicable and appropriate regulation

information

General Hazards

Following are descriptions of general hazards and unsafe practices that could result in death, severe

injury, or product damage. Specific warnings and cautions not appearing in this section are found

throughout the manual.

Warning: Serious Personal Injury

This Class 4 CO2 laser product emits invisible infrared laser radiation in the 9.3–10.6 μm wavelength

band.

Because direct or diffuse laser radiation can inflict severe corneal injuries, always wear eye protection

when in the same area as an exposed laser beam.

Do not allow the laser beam to contact a person!

This product emits an invisible laser beam that is capable of seriously burning human tissue.

Always be aware of the beam’s path and always use a beam block while testing.

Warning: Serious Personal Injury

Do not allow laser radiation to enter the eye by viewing direct or reflected laser energy.

CO2 laser radiation can be reflected from metallic objects even though the surface is darkened. Direct

or diffuse laser radiation can inflict severe corneal injuries leading to permanent eye damage or

blindness. All personnel must wear eye protection suitable for CO2 radiation, e.g., 9.3–10.6 μm when

in the same area as an exposed laser beam.

GENERAL HAZARDS (CONTINUED) PAGE |14

General Hazards (Continued)

p100/150 lasers should be installed and operated in manufacturing or laboratory facilities by trained

personnel only. Due to the considerable risks and hazards associated with the installation and

operational use of any equipment incorporating a laser, the operator must follow product warning labels

and instructions to the user regarding laser safety. To prevent exposure to direct or scattered laser

radiation, follow all safety precautions specified throughout this manual and exercise safe operating

practices per ANSI Z136.1-2014, Safe Use of Lasers at all times when actively lasing.

Due to the specific properties of laser light, a unique set of safety hazards that differ from other light

sources must be considered. Just like light, lasers can be reflected, refracted, diffracted, or scattered.

Warning: Serious Personal Injury

Do not allow laser radiation to enter the eye by viewing direct or reflected laser energy.

CO2 laser radiation can be reflected from metallic objects even though the surface is darkened. Direct

or diffuse laser radiation can inflict severe corneal injuries leading to permanent eye damage or

blindness. All personnel must wear eye protection suitable for CO2 radiation, e.g., 9.3–10.6 μm when

in the same area as an exposed laser beam.

Eye wear protects against scattered energy but is not intended to protect against direct viewing of

the beam—never look directly into the laser output aperture or view scattered laser reflections from

metallic surfaces.

Enclose the beam path whenever possible. Exposure to direct or diffuse CO2 laser radiation can

seriously burn human or animal tissue, which may cause permanent damage.

This product is not intended for use in explosive, or potentially explosive, atmospheres!

Materials processing with a laser can generate air contaminants such as vapors, fumes, and/or

particles that may be noxious, toxic, or even fatal. Material Safety Data Sheets (MSDS) for materials

being processed should be thoroughly evaluated and the adequacy of provisions for fume extraction,

filtering, and venting should be carefully considered. Review the following references for further

information on exposure criteria:

ANSI Z136.1-2014, Safe Use of Lasers, section 7.3. U.S. Government’s Code of Federal Regulations: 29

CFR 1910, Subpart Z. Threshold Limit Values (TLV’s) published by the American Conference of

Governmental Industrial Hygienists (ACGIH).

It may be necessary to consult with local governmental agencies regarding restrictions on the venting

of processing vapors.

The use of aerosol dusters containing difluoroethane causes “blooming”, a condition that significantly

expands and scatters the laser beam. This beam expansion can affect mode quality and/or cause

l t t d b d th fi f ti l l t i th t ibl d i

GENERAL HAZARDS (CONTINUED) PAGE |15

General Hazards (Continued)

Figure 2-2 Always wear safety glasses or protective goggles with side shields to reduce the risk of damage to the

eyes when operating the laser.

A CO2 laser is an intense energy source and will ignite most materials under the proper conditions.

Never operate the laser in the presence of flammable or explosive materials, gases, liquids, or vapors.

Safe operation of the laser requires the use of an external beam block to safely block the beam from

traveling beyond the desired work area. Do not place your body or any combustible object in the path of

the laser beam. Use a water-cooled beam dump or power meter, or similar non-scattering,

noncombustible material as the beam block. Never use organic material or metals as the beam blocker;

organic materials, in general, are apt to combust or melt and metals act as specular reflectors which may

create a serious hazard outside the immediate work area.

Always wear safety glasses or protective goggles with side shields to reduce the risk of damage to the

eyes when operating the laser.

Other Hazards

The following hazards are typical for this product family when incorporated for intended use: (A) risk of

injury when lifting or moving the unit; (B) risk of exposure to hazardous laser energy through

unauthorized removal of access panels, doors, or protective barriers; (C) risk of exposure to hazardous

laser energy and injury due to failure of personnel to use proper eye protection and/or failure to adhere

to applicable laser safety procedures; (D) risk of exposure to hazardous or lethal voltages through

unauthorized removal of covers, doors, or access panels; (E) generation of hazardous air contaminants

that may be noxious, toxic, or even fatal.

Warning: Serious Personal Injury

Never use organic material or metals as a beam blocker. There are very few exceptions, e.g., black

anodized metal such as aluminum because this is not reflective surface.

Warning: Serious Personal Injury

“Caution - The use of controls or adjustments of performance of procedures other than those

specified herein may result in hazardous radiation exposure.”

Other manuals for SYNRAD Pulstar p100

1

This manual suits for next models

1

Table of contents

Other Novanta Measuring Instrument manuals

Novanta

Novanta Synrad ti Series User manual

Novanta

Novanta f201 User manual

Novanta

Novanta ventus with mpc6000 User manual

Novanta

Novanta ATI Axia80 User manual

Novanta

Novanta i401 User manual

Novanta

Novanta v40 User manual

Novanta

Novanta JADAK FM-8 User manual

Novanta

Novanta i401 User manual

Novanta

Novanta 32-1 Laser User manual

Novanta

Novanta SYNRAD Pulstar p100 User manual