vii

SYNRAD i401 Operator’s Manual Version 2.0

Warranty information

This is to certify that Firestar®i401 lasers are guaranteed by SYNRAD, Inc. to be free of all defects in

materials and workmanship for a period of one year from the date of purchase. This warranty does not

apply to any defect caused by negligence, misuse (including environmental factors), accident, alteration,

or improper maintenance. This includes, but is not limited to, damage due to corrosion, condensation, or

failing to supply properly conditioned purge gas.

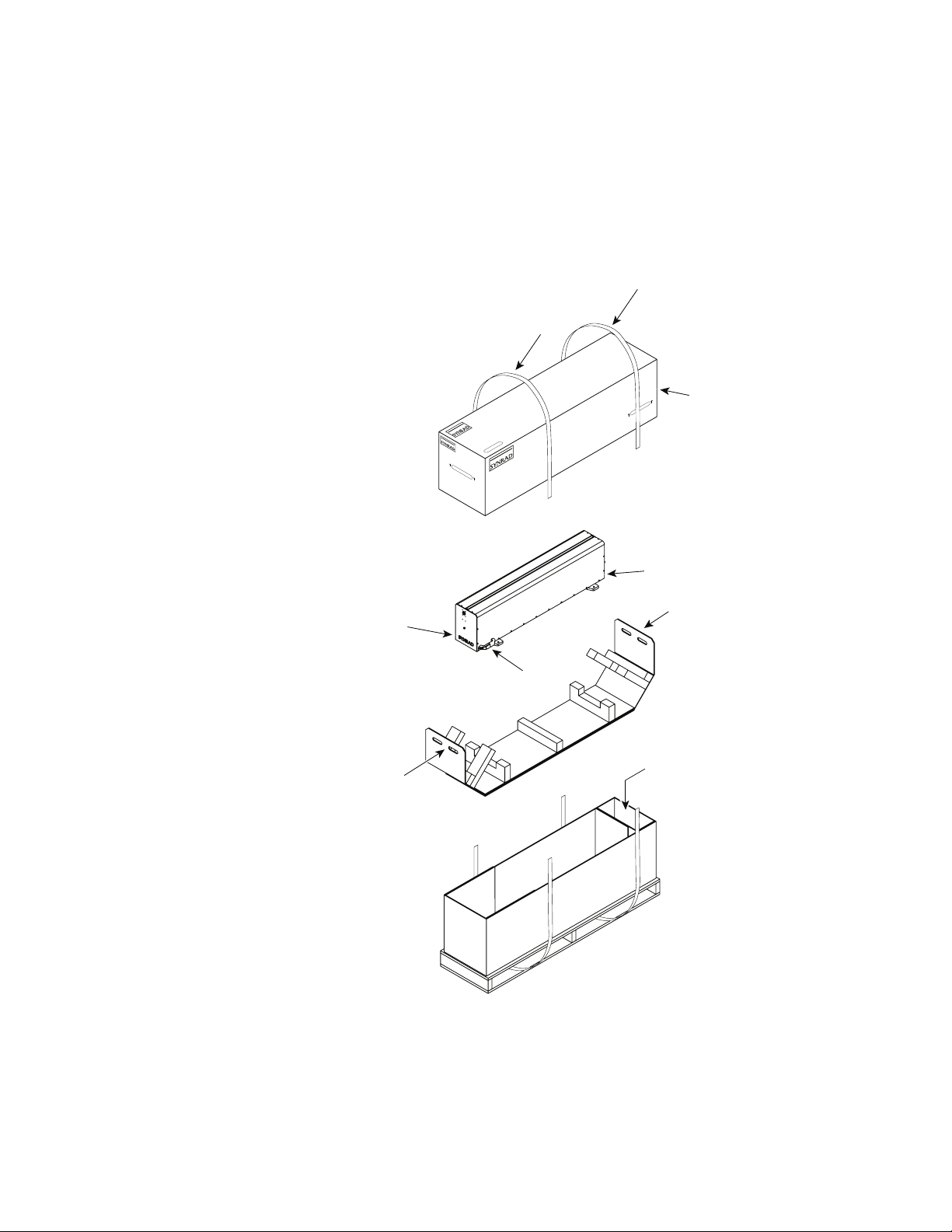

We request that you examine each shipment within 10 days of receipt and inform SYNRAD, Inc. of any

shortage or damage. If no discrepancies are reported, SYNRAD shall assume the shipment was delivered

complete and defect-free.

If, within one year from the date of purchase, any part of the Firestar i401 laser should fail to oper-

ate, contact the SYNRAD Customer Service department at 1.800.SYNRAD1 (outside the U.S. call

1.425.349.3500) and report the problem. When calling for support, please be prepared to provide the date

of purchase, model number and serial number of the unit, and a brief description of the problem. When

returning a unit for service, a Return Authorization (RA) number is required; this number must be clearly

marked on the outside of the shipping container in order for the unit to be properly processed. If replace-

ment parts are sent to you, then you are required to send the failed parts back to SYNRAD for evaluation

unless otherwise instructed.

If your Firestar i401 laser fails within the rst 45 days after purchase, SYNRAD, Inc. will pay all shipping

charges to and from SYNRAD when shipped as specied by SYNRAD Customer Service. After the rst 45

days, SYNRAD will continue to pay for the costs of shipping the repaired unit or replacement parts back

to the customer from SYNRAD. The customer, however, will be responsible for shipping charges incurred

when sending the failed unit or parts back to SYNRAD or a SYNRAD Authorized Distributor. In order to

maintain your product warranty and to ensure the safe and ecient operation of your Firestar i401 laser,

only authorized SYNRAD replacement parts can be used. This warranty is void if any parts other than

those provided by SYNRAD, Inc. are used.

SYNRAD, Inc. and SYNRAD Authorized Distributors have the sole authority to make warranty state-

ments regarding SYNRAD products. SYNRAD, Inc. and its Authorized Distributors neither assumes nor

authorizes any representative or other person to assume for us any other warranties in connection with the

sale, service, or shipment of our products. SYNRAD, Inc. reserves the right to make changes and improve-

ments in the design of our products at any time without incurring any obligation to make equivalent

changes in products previously manufactured or shipped. Buyer agrees to hold SYNRAD harmless from

any and all damages, costs, and expenses relating to any claim arising from the design, manufacture, or use

of the product, or arising from a claim that such product furnished Buyer by SYNRAD, or the use thereof,

infringes upon any Patent, foreign or domestic.