Novanta Synrad ti Series User manual

1 QSG ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6 Ver 2.0

FH

MARKING HEAD

FLYER

a Novanta company

ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6

1. Under your ti Series laser at the bottom of the box you will nd the mounting hardware/compo-

nents kit. The Marking Head hardware/components kit is located in the top shipping compo-

nents box. Don’t forget to save all shipping containment including plug covers and set them aside.

Important

Note:

Keep All Foam and Packaging, you will need to re-use it when moving your laser to

prevent damage that could void your warranty. Refer to this guide and the Technical

Reference chapters in the laser’s Operation Manual when re-packaging for shipping

and/or relocation. Remove all accessory items not originally attached to the laser prior

to re-packaging for shipping.

2. Upon arrival, inspect all shipping containers for signs of damage. If you discover shipping damage,

document the damage (photographically if possible), then immediately notify the shipping

carrier (responsible party for any transportation damage) and SYNRAD®. See the inventory section

with in the Introduction chapter of the Operation Manual for packaging list(s).

Laser and Marking Head Unpacking:

Note: If shipped completely assembled, jump to the cooling section of this guide.

Important

Note: Read all Danger, Warning, Caution terms, symbols, and instructions located

in the (Laser Safety Hazard information) sections in the ti-Series Laser Operation Man-

uals located on our website http://synrad.com/synrad/docroot/resources/libraries/

manuals.

1.1 Lifting the ti-Series laser correctly by

holding in the middle, do not carry laser

by the mounting feet, this can disturb

alignment.

1.2 Ti-Series laser mounting/component kit

for the laser and the FH FlyerMarking Head

(Inset).

a Novanta company

ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6

2 QSG ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6 Ver 2.0

Important

Note:

Caution! When packing the marking head for relocation or shipment, noth-

ing can be on the sides of the unit at any time as damage will occur. All box

components must be stowed as they were when they arrived.

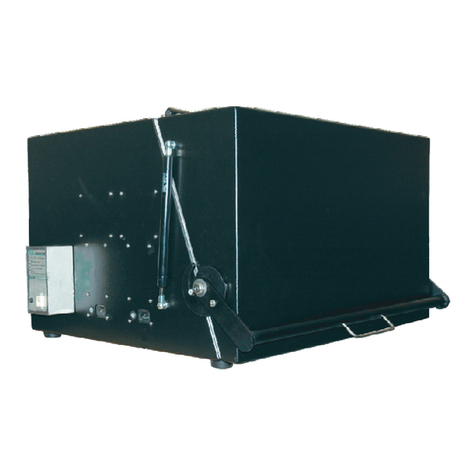

2.1 Place the unit with foam packaging on a

rm surface, remove foam end cap,

notice foam notch locations for ports

and interfaces.

Lift both the both the marking

head and the foam packaging out

of the box.

Please refer to the examples above and the laser’s Operation Manual drawings located at the end of

the Technical Reference Chapter.

The wire harness can be damaged in

shipping if not re-packaged as shipped!

Top Foam

notch

Bottom

Foam notch

Don’t forget to remove the three (3) cap

screws on the lens aperture cover if a

focusing lens is ordered.

3 QSG ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6 Ver 2.0

FH

MARKING HEAD

FLYER

a Novanta company

ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6

Laser Unpacking:

Important

Note:

Caution! Unpacking the wire harness incorrectly can damage the laser.

Keep All Foam and Packaging, you will need to re-use it when moving your

laser. Refer to this guide and the Getting Started/Technical Reference chap-

ters in the laser’s Operation Manual when re-packaging for shipping and/or

relocation.

Caution! When packing the laser for relocation or shipment, nothing can be on the sides

of the laser at any time as damage will occur. The skin on the sides of the laser is fragile!

All box components must be stowed under the laser.

The wire harness will be damaged in shipping if not re-packaged as shown above.

3. Unseat the wiring by sliding the harness out of the notch, then down and out of the foam as shown

above.

3.1. Locate the wire harness in

side one of the foam end caps.

3.3. Drape the wire harness across

the top of the laser housing when

carrying.

3.4. Don’t forget the hardware

at the bottom of your box!

3.2. Push the wire harness through the

notch in the foam.

4. Locate the laser hardware kit at the bottom of this box under the laser.

a Novanta company

ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6

4 QSG ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6 Ver 2.0

Mounting your Laser:

Note: Mounting feet and/or rails are optional, for complete details, refer to the Ti Series Operator’s

Manual. Remove the laser aperture self-adhesive lm before mounting to the rail.

Don’t tighten the path enclosure screws until the laser is mounted securely to the rail.

SYNRAD does not recommend mounting lasers in a vertical, (head and/or tail down) position. Please

contact the factory for limitations as a vertical orientation increases the risk of damage to the lasers optics.

The laser’s mounting feet are precisely aligned and shimmed at the factory to ensure alignment between

the marking head and the Mounting Rail. Do not loosen or remove the mounting feet from the laser.

See the FH Flyer Marking Head Operator’s Manual for further details.

5. Before mounting the laser to the rail, ensure the aperture seal is removed.

6. Locate the Mounting Hardware Kit ( ) path enclosure tube, marking head & laser

hardware.

DB9

CONNECTOR

AUXILIARY

POWER

DC POWER

CABLES

POWER

LED

LASE LED

FUSE

KEYSWITCH

PWR LASE

CTRL

FUSE

CARBON DIOXIDE LASER

ON

5 SEC DELAY

COMMAND

INPUT

STATUS

LASER EXIT

APERTURE

SHUTTER

SWITCH

DIODE POINTER

POWER CONNECTOR

ON OFF

APERTURE

SEAL

INVISIBLE LASER RADIATION

IS EMITTED FROM THIS

APERTURE

AVOID EXPOSURE

OPTICAL

ACCESSORY

MOUNTING (x6)

O

F

F

A

V

O

ID EXP

OSU

RE

5.1 Remove the

aperture seal.

6.1 Path enclosure tube.

6.2 6-32 x 1” Laser Mounting socket head

capscrews.

6.3 1/4-20 x 3/4” Marking Head Mounting

socket head capscrews.

6.4 8-32 x 1/4” Marking Head Mounting

button head socket screws.

6.5 Laser & Marking Head Mounting Kit(s).

5 QSG ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6 Ver 2.0

FH

MARKING HEAD

FLYER

a Novanta company

ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6

Notch

8.2 l-bracket mounting holes and notch locations

on the rail.

Note: Assure the rail notch is on the Marking Head

side of the rail.

Notch

3

12

4

8.3 Secure the l-bracket to the

rail.

7. Remove the dust cover & set aside, from the rear end of the marking head, unwrap the mounting

rail, set it on a rm surface. Orient the rail so that the l-bracket can be placed on the notch end of

the rail.

8. Mount the l-bracket to the rail using the (4) 1/4-20 x 3/4” socket head capscrews as shown in the

following gures.

8.1 Notch end of the rail.

Marking head side

of the rail.

Laser feet Dowel pins.

7.1 Dust Cover

a Novanta company

ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6

6 QSG ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6 Ver 2.0

9.1 Marking Head secured to

the L-bracket.

Mounting your Marking Head onto a Rail (Continued):

9. Remove the dust cover & set aside, from the rear end of the marking head, unwrap the mounting

rail, set it on a rm surface. Orient the rail so that the L-bracket can be placed on the notch end of

the rail.

Dowel pins

Important

Check Point: The anodized blanking plate & dust cover are removed from the Marking Head.

The Marking Head is mounted adjacent to the notch on the rail.

Refer to the appropriate chapter for more mounting details and the technical

drawings in the Ti Series Operation Manual.

7 QSG ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6 Ver 2.0

FH

MARKING HEAD

FLYER

a Novanta company

ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6

1

2

Mounting your Laser onto a Rail:

10. Ease the laser forward so the dowel pins on both mounting feet drop into their respective holes on

the rail. Install/tighten the four (4) 6/32 x 1” socket head capscrews. See the gure below.

10.1 Attach the laser by it’s mounting feet securely to the rail.

Important

Note:

Calibration void if shim bolts are adjusted, if your laser has mounting feet as shown

above, careful not to carry or handle the laser by the feet to minimize misalignment risk.

3

4

Important

Note: Do not use any type of jackscrew arrangement as this will twist the baseplate and

may distort the tube.

a Novanta company

ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6

8 QSG ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6 Ver 2.0

9. After both the laser and the marking head are mounted to the rail, place the spring-loaded path

enclosure tube as shown below.

Note: The recommended mounting orientation for the ti Series is horizontal.

Refer to the drawings within the Ti Series Operation Manual, see the

Technical Reference chapter for further information.

Important

Note:

Consult the factory for further mounting angle guidance outside >20% from the

horizontal. When mounting the laser, use only one metric or SAE fastener per

mounting tab on the baseplate. Do not use any type of jackscrew arrangement

as this will twist the baseplate and may distort the tube.

9.1 Compress the spring-loading path enclosure

tube and place the larger end facing the mark-

ing head (on the L-bracket).

Mounting your Laser onto a Rail (Continued):

9 QSG ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6 Ver 2.0

FH

MARKING HEAD

FLYER

a Novanta company

ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6

10. Secure the path enclosure tube to the L-bracket with four (4) 8-32 x 1/4” button head socket screws

as shown below.

Mounting your Laser onto a Rail (Continued):

10.1 Assure the laser & marking head is securely mounted to the rail beforehand.

10.2 Should look like this.

1

2

34

Not shown

a Novanta company

ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6

10 QSG ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6 Ver 2.0

Cooling:

Important

Note:

Use distilled water as the coolant. If glycol is necessary, add no more than 10% by

volume. When filling your chiller, use at least 90% distilled or tap water by volume. If

you must use glycol, do not add more than 10% by volume. See the technical reference

chapter in the ti Series Operation Manual for the dew point table and cooling specifica-

tions.

11. Locate the Ship Kit ( ) Cooling quick-disconnect ttings and 1/2 inch polyethylene

tubing. See the 48-1/48-2 Cooling connections (rear interface) in the gure below.

Operating the laser with a coolant temperature below the dew point of the surrounding air may cause

condensation to occur that will damage the laser! The setpoint temperature MUST be maintained above

the dew point temperature.

Water In

from chiller

Water Out

to chiller

Attention: The stability of the unit will be aected

if the water in/out is reversed and if not

run in parallel!

When coolant temperature is lower than the dew point (the temperature at which moisture condens-

es out of the surrounding air), condensation forms inside the laser housing leading to failure of laser

electronics as well as damage to optical surfaces.

The greatest risk of condensation damage occurs when water-cooled lasers are run in a high heat/high

humidity environment and the chiller’s coolant temperature is colder than the dew point temperature of the

surrounding air or when the system is shut down, but coolant continues to ow through the laser for ex-

tended periods of time.

The chiller’s temperature setpoint must always be set above the dew point temperature. In cases where this

is not possible within the specied coolant temperature range of 18 °C to 22 °C (64 °F to 72 °F), then the fol-

lowing steps MUST be taken to reduce the risk of condensation damage.

A. Stop coolant ow when the laser is shut down.

B. Increase coolant ow by an additional 3.8 LPM (1.0 GPM).

C. Air-condition the room or the enclosure containing the laser.

D. Install a dehumidier to reduce the humidity of the enclosure containing the laser.

11 QSG ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6 Ver 2.0

FH

MARKING HEAD

FLYER

a Novanta company

ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6

Cooling (Connued):

Guidelines for cutting and installing tubing

Cut tubing lengths generously to allow for trimming.

Cut tubing squarely; diagonal cuts may not seal properly. Trim away any burrs if the cut is “ragged”.

Avoid excessive stress on ttings by creating a gentle radius when bends in the tubing are close to

ttings. Bending tubing too sharply will compromise the sealing properties of the tting.

Never allow the tubing to kink, since kinking severely restricts coolant ow.

Push tubing completely into the tting, then pull the tubing to verify that it is locked into place.

If tubing needs to be disconnected from a tting:

First push and hold the tubing slightly into the tting. Next push the white tting ring evenly towards

the tting, and then pull the tubing free.

After disconnecting tubing from a tting, trim 12.7 mm (0.5 in) from its end before reconnecting.

Trimming the end of the tubing before reconnecting provides an undisturbed sealing surface.

If your integrated laser application uses metric cooling tubing, we recommend the installation of

tubing adaptors to convert cooling kit ttings from 1/4”tubing to 6 mm metric tubing and 3/8”

tubing to 8 mm metric tubing. These tubing adaptors are available from many tubing and tting

manufacturers.

Important

Note: Choosing the correct coolant temperature is important to the proper operation and lon-

gevity of your laser otherwise internal condensation damage will occur!

Reference the dew point chart for temperatures and range of air temperature and relative humidity values

in the technical references chapter of the Operation Manual.

Remember that the laser’s coolant temperature must be set above dew point temperatures.

Do not ow coolant through the laser for an extended period of time

when the laser is shutdown. This causes condensation to form inside the

laser which may result in catastrophic damage to internal optics and elec-

tronic circuits.

Inlet cooling water temperature must always be maintained above the

dew point to prevent condensation and water damage to your laser.

Caution

possible equipment

damage

a Novanta company

ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6

12 QSG ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6 Ver 2.0

Note: The negative (–) side of the DC input to the laser is internally connected so that the laser chassis

serves as DC power ground.

Power Connections:

12. Verify that input AC power to the DC power supply is physically locked out or disconnected.

13. Connect the Marking Head DC power VDC cable into the Marking Head’s power supply.

You should isolate the laser’s DC power supply so that the only grounded connection is at the laser.

Alternatively, you can mount the laser chassis on an insulating pad or lm in order to electrically isolate

the DC return from the chassis ground.

13.1 DC Power connection locations

(for the Marking Head) to the

power supply.

Green

( )

Red

(+)

Black

(-)

13 QSG ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6 Ver 2.0

FH

MARKING HEAD

FLYER

a Novanta company

ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6

14.1 DC Power

Power Connections (Continued):

Do not reverse polarity when connecting the DC Power cable between the DC power supply and the

ti-Series laser. Damage to the power supply may occur!

Because AC input connections and requirements vary from facility to facility, customers must provide the

AC power cable or wiring.

Attach the red (+) wire(s) from the DC Power cable to the positive (+) 48 VDC output terminal and attach

the black (-) wire(s) from the DC Power cable to the negative (-) 48 VDC output terminal.

14. Connect the negative (black) and the positive (red) DC power into the laser’s power supply.

15. Connect one side of the 180–264V AC line to the input terminal labeled “AC/L”.

Important

Note:

16. Connect the other side of the AC line to the input terminal labeled “AC/N”.

17. On the AC input section of the PS-48 power supply, connect the ground wire, typically green, to the

input terminal labeled with the ground symbol.

The ti-Series laser requires a DC power supply capable of providing 48 VDC at 18-35 A

depending on model, refer to the specications within the laser’s operation manual.

For the ti-Series laser, SYNRAD® recommends the PS-48 DC power supply which pro-

vides a maximum of 50A at 48 VDC. AC input requirements for the PS-48 supply are

180-264 VAC, single phase (1Ø), 9.4 A max (@208 VAC), 47-63 Hz. Please refer to the

corresponding power supply manual located on our website.

a Novanta company

ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6

14 QSG ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6 Ver 2.0

Control Connections:

18. Connect the laser’s control BNC interface to the Marking Head’s laser control port.

BNC

Connector

Important

Note:

All control connections to Firestar ti-Series lasers are made through the 15-pin User

I/O connector on the laser’s rear panel. The User I/O port receives power commands

from SYNRAD’s UC-2000 Universal Laser Controller, or FH marking head, and also

serves as the connection point for auxiliary signals between the laser and any parts

handling, automation, or monitoring equipment.

Always use shielded cable when connecting your PWM Command signal

source to PWM Positive/PWM Negative inputs.

In electrically-noisy environments, long lengths of unshielded wire act like

an antenna and may generate enough voltage to trigger un-commanded

lasing.

Warning

Serious

personal

injury

81.1 Assure the ferrite bead is

on the Marking Head side.

15 QSG ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6 Ver 2.0

FH

MARKING HEAD

FLYER

a Novanta company

ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6

19.1 Control connection locations

(for the Marking Head).

19. Connect the other end of the BNC cable to the control input, 15 pin User I/O, via the Quick Start

Plug QSP (Optional) located on the rear end of the laser. (Refer to the gure on the following page.)

20. The Ethernet connector is ready to be plugged into the PC’s Ethernet port and the USB cable is ready

to be plugged from the FH Flyer Marking Head to the PC.

Control Connections (Continued):

QSP (optional)

and BNC

To PC

USB port

20.1 To PC Ethernet port

Caution: The Quick Start Plug bypasses the laser’s safety interlock function, potentially

exposing personnel to hazardous invisible laser radiation.

a Novanta company

ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6

16 QSG ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6 Ver 2.0

To PC

Ethernet

port

BNC

Connector

Should look something

like this.

DC

Power

19.2 From laser I/O port to Marking Head BNC port.

QSP (optional)

and BNC

17 QSG ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6 Ver 2.0

FH

MARKING HEAD

FLYER

a Novanta company

ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6

Laser Markers are pre-congured at the factory to a xed address of 192.168.100.100. This allows you to

make a peer-to-peer Ethernet connection. Your computer’s Ethernet settings are determined by your facil-

ity’s computer network. The FH Marking Head requires a connection to a computer with a static IP address

if not connected to a local network (Peer to Peer). Reference the FH Flyer Operation Manual located on our

website for more information.

Set your computer’s static IP address

21. Disconnect the computer from your local network.

22. Turn o Dynamic Host Conguration Protocol (DHCP), if enabled, and create a static IP address for

your computer.

Note: The exact steps may vary depending on your operating system.

a

From the Start menu, go to Settings and choose Network Connections.

b

Double-click on the appropriate Local Area Network (LAN).

c

Locate the LAN’s Internet Protocol (TCP/IP) properties.

d

Select “Use the following IP address:” and enter the following information:

IP Address: 192.168.100.101

Subnet Mask: 255.255.255.0

e

Click OK to submit the changes.

Control Connections (Continued):

a Novanta company

ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6

18 QSG ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6 Ver 2.0

17. Before upgrading to a newer version of WinMark pro, backup all existing .mkh mark les and unin-

stall prior version(s) of WinMark pro software.

18. Download the latest version 6 WinMark pro driver from our website https://www.synrad.com/syn

rad/docroot/products/marking_heads_software/winmark-sw. Exit all programs prior to Installation.

19. To install WinMark pro v6, and associated device drivers on a Windows®7 or Windows®Vista™operat-

ing system, right-click the setup.exe le and choose ‘Run as Administrator…’.

(WinMark®) v6 Software Installation:

20. To install WinMark Pro v6, and associated device drivers, on a Windows®operating system, double-

click the setup.exe le.

21. WinMark Pro v6 is a Microsoft .NET™ Framework-based application. If Microsoft .NET Framework

Service Pack 1, or higher, is not installed on the computer, the installer will prompt you to click ‘Ac-

cept’ to install the .NET Framework. You must have the .NET Framework runtime and associated les

installed to run WinMark Pro.

Important

Note: When upgrading from a v4 build to version v6, the WinMark Pro installer automatical-

ly performs a “clean install” because v6 is uses a dierent subset of registry keys. The

“Perform Clean Installation” and “Keep Current Program Settings” options are grayed

out to indicate this installation is a“clean installation”.

Upgrading from one v6 build to another does allow the option of preserving existing WinMark settings

in the computer’s System Registry. Choose Yes to preserve current WinMark Pro v6 registry settings

including custom date code formats, object defaults, shift codes, auto startup info, and saved serial

numbers. Choose No to erase all previous WinMark v6 Registry entries and perform a clean installation.

Note: Due to Microsoft’s implementation of registry virtualization, Windows Vista may re-

quire you to log on as an Administrator to perform certain functions like le impor-

tation or to save custom date code formats.

Laser Marking Software (WinMark®):

Important

Note:

Prior to installation of the WinMark pro laser marking software on your computer,

review the requirements in the WinMark pro Operation Manual, remove power or

unplug the USB cable from the FH Flyer marking head to prevent windows from ar-

bitrarily assigning a USB driver that is not compatible with Flyer’s USB port protocols.

Note: Find the WinMark pro v6 Software release notes on our website. Refer to

WinMark’s website for supported operating systems and the WinMark Pro

Operation Manual.

19 QSG ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6 Ver 2.0

FH

MARKING HEAD

FLYER

a Novanta company

ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6

WinMarkpro v6 Installation (continued):

Note: If WinMark Pro is un-installed, the .NET package is not removed, because these les may be

used by other applications installed after the original WinMark installation.

22. When the .NET Framework installation us complete, reboot if prompted to do so. Otherwise the Win-

Mark installer will continue.

23. If Microsoft C++ Redistributable x86 le runtime components are not installed on the computer, the

installer will prompt you to click ‘Install’ to install C++ Redistributable les. You must have these les

installed to run WinMark Pro.

24. Follow instructions in the installer dialog boxes to complete the WinMark Pro installation. You must

click ‘I Agree’ to accept the WinMark Pro license agreement and continue the installation.

25. After installation is complete, remember to turn on any anti-virus software.

a Novanta company

ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6

20 QSG ti-Series™ Water Cooled Laser, FH Marking Head, kit & WMPv6 Ver 2.0

WinMark Launcher:

26. As part of the software installation, WinMark Launcher (Launcher.exe) is placed in the Program Files/

WinMark folder and a shortcut is placed on the desktop. Launcher allows non-administrative

operators to load existing .mkh les for marking without opening WinMark’s Drawing

Editor by selecting the ‘Open Drawing...’ from the le menu.

27. To add an Admin password so operators cannot modify a drawing select ‘Modify Drawing...’ which

then opens the WInMarkpro application.

26.1 Opening an existing *.mkh le.

27.1 Modifying an existing *.mkh le.

27.2 Opening WinMarkpro through the Launcher.

Table of contents

Other Novanta Measuring Instrument manuals

Novanta

Novanta ATI Axia80 User manual

Novanta

Novanta vi30 User manual

Novanta

Novanta SYNRAD Pulstar p100 User manual

Novanta

Novanta i401 User manual

Novanta

Novanta f201 User manual

Novanta

Novanta v30 User manual

Novanta

Novanta 32-1 Laser User manual

Novanta

Novanta i401 User manual

Novanta

Novanta p400 OEM Series User manual

Novanta

Novanta ventus with mpc6000 User manual