NovaTec BC-1 User manual

BC-1 BLOWBACK

CONTROL PACKAGE

BC-1-11

115 VAC

BC-1-24

24 VDC

© NOVATEC, Inc. 2018 AllRights Reserved BC-1 IM 8 FEB 2018

BC-1 IM 8 FEB 2018

© 2018 NOVATEC, Inc. All RightsReserved

Page 2

NOTES:

Please record the following

information, which is specific to

this piece of equipment, in the

space provided. Our Parts/Service

Department will need these

numbers to properly respond to

any of your requests.

Instruction Manual: BC-1 IM 8 FEB 2018

Model #:

Serial #

DISCLAIMER: NOVATEC, Inc. shall not be liable for

errors contained in this Instruction Manual nor for

misinterpretation of information contained herein.

NOVATEC shall not, in any event, be held liable for any

special, indirect or consequential damages in

connection with performance or use of this information.

BC-1 IM 8 FEB 2018

© 2018 NOVATEC, Inc. All RightsReserved

Page 3

Contents

1.0 DRAWING LIST.................................................................................................................4

2.0 SPECIFICATIONS.............................................................................................................4

3.0 UNPACKING AND INSPECTION......................................................................................4

4.0 INSTALLATION FOR 115 VAC.........................................................................................5

5.0 INSTALLATION FOR 24VDC............................................................................................6

6.0 OPERATION .....................................................................................................................7

5.1

Control Description.........................................................................................................7

5.2

Preset Controller Values................................................................................................7

5.3

Changing Controller Values...........................................................................................7

7.0 WARRANTY......................................................................................................................8

Appendix:

Drawings: BC-1-24

BC-1-11

BC-1 IM 8 FEB 2018

© 2018 NOVATEC, Inc. All RightsReserved

Page 4

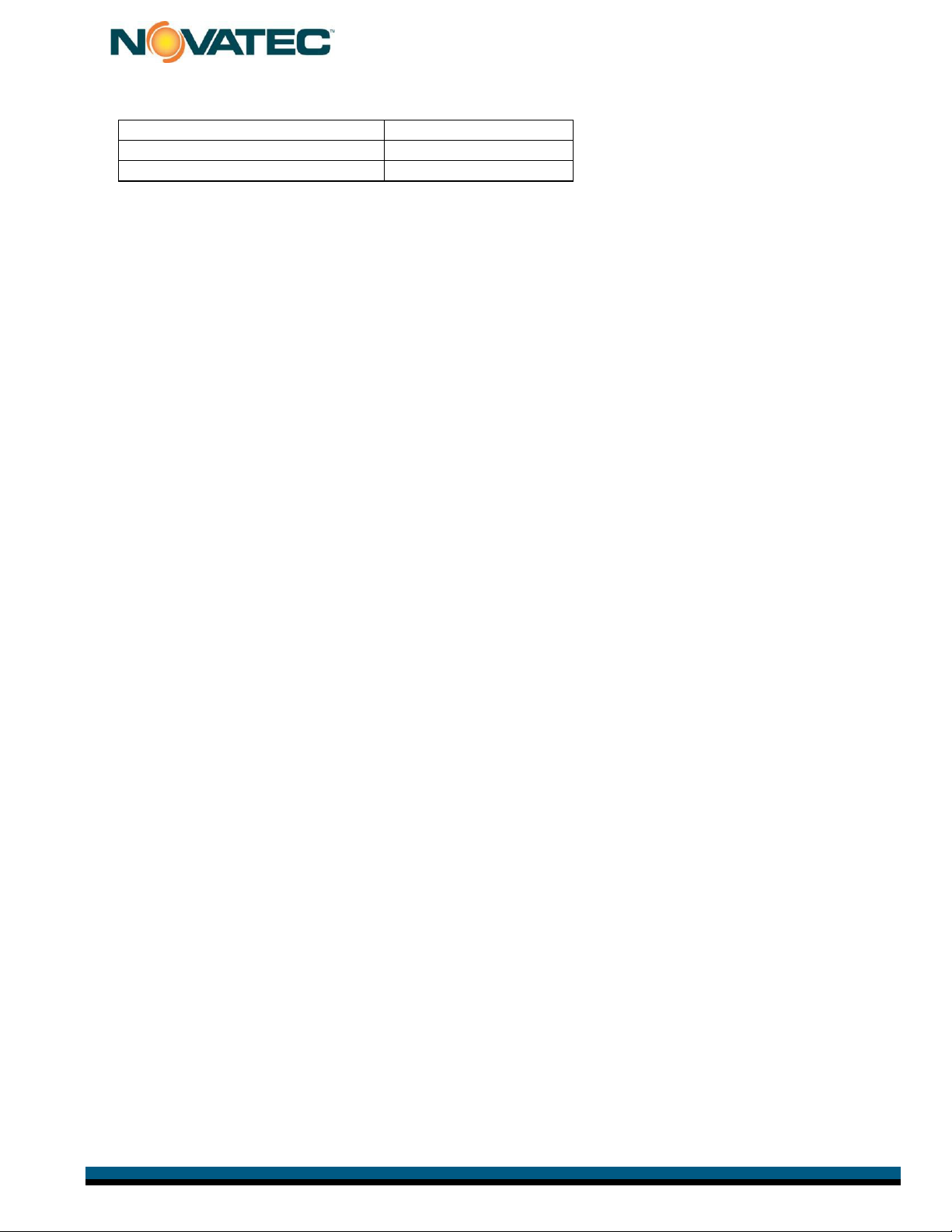

1.0 DRAWING LIST

BLOWBACK CONTROLLER

PART NUMBER/DWG

115 VOLTS AC

BC-1-11

24 VDC

BC-1-24

2.0 SPECIFICATIONS

Novatec Blowback Controllers are designed to control the blowback solenoid of a vacuum

receiver. Compressed air from the blowback solenoid pulses the pellet screen to remove

plastic particles.

The blowback controller is used along with the main MCS panel when blowback is

necessary. The MCS supplies power to the blowback controller as well as a station-loading

signal that is wired in parallel to the station“T” valve. When the MCS de-energizes the

station “T” valve the blowback controller pulses the blowback solenoid for a preset number of

times. While the solenoid is pulsing, a contact on the blowback controller wired in series with

the station demand level switch opens preventing the station from loading until the blowback

cycle is complete. Once blowback is finished the contact closes allowing the receiver to

begin filling once the demand level switch closes as well.

3.0 UNPACKING AND INSPECTION

Novatec Blowback Controllers are shipped complete with all controls for automatic operation.

Completely inspect the unit for damage. The units are packaged securely, but vibration and

mishandling during transit can cause damage.

BC-1 IM 8 FEB 2018

© 2018 NOVATEC, Inc. All RightsReserved

Page 5

4.0 INSTALLATION FOR 115 VAC

WARNING: IMPORTANT INFORMATION

Danger! Disconnect all voltage before inspecting or servicing the BLOWBACK

CONTROLLER. Only properly trained, qualified technicians should operate or service

the BLOWBACK CONTROLLER.

Dangerous Voltage! Do not put your finger or any object in the program SD

card slot. If the power supply is not connected properly, the slot for the SD card

may carry voltage. The SD card cover must be in place at all times. NOTE: the

SD card is optional and is not needed for normal operation.

All national and local electrical, building, and safety codes need to be followed. Proper

grounding of all equipment is important. Check the electrical wiring schematic for wiring

numbers and details.

Wiring for 115 VAC

1. Mount the LOGO control box in a secure location.

1. Remove screws (item number 3 in drawing BC-1-11 allowing the cover plate to be

removed.

3.

Remove the cover plate (item number 2 in drawing).

4.

Connect wire nut (wire number 1 in drawing) to the 115 VAC hot power supply

located inside the main MCS control panel.

Note: There are two wires numbered 2. One is for connecting to the 115 VAC

neutral in the main MCS control panel and the other one is for connecting to the

blowback solenoid valve.

5.

Connect wire nut (wire number 2 in drawing) to the neutral conductor located inside the

main MCS control panel.

6.

Connect wire nut (wire number 2 in drawing) to the blowback solenoid located at the

vacuum receiver

7.

Connect wire nut (wire number 4 in drawing) to the blowback solenoid located at the

vacuum receiver.

8.

Connect wire nut (wire number 8 in drawing) to the 115 VAC hot station valve output

requiring blowback.

9.

Connect wire nuts (wire numbers 3, MCSMAT Demand in drawing) in series with the

demand level switch of the station requiring blowback.

BC-1 IM 8 FEB 2018

© 2018 NOVATEC, Inc. All RightsReserved

Page 6

5.0 INSTALLATION FOR 24VDC

WARNING: IMPORTANT INFORMATION

Danger! Disconnect all voltage before inspecting or servicing the BLOWBACK

CONTROLLER. Only properly trained, qualified technicians should operate or service

the BLOWBACK CONTROLLER.

Dangerous Voltage! Do not put your finger or any object in the program SD

card slot. If the power supply is not connected properly, the slot for the SD card

may carry voltage. The SD card cover must be in place at all times. NOTE: the

SD card is optional and is not needed for normal operation.

All national and local electrical, building, and safety codes need to be followed. Proper

grounding of all equipment is important. Check the electrical wiring schematic for wiring

numbers and details.

Wiring for 24VDCC

1.

Mount the LOGO control box in a secure location.

2.

Remove screws (item number 3 in drawing BC-1-24 allowing the cover plate to be

removed.

3.

Remove the cover plate (item number 2 in drawing).

4.

Connect wire nut (wire number 1 in drawing) to the 24 VDC hot power supply

located inside the main MCS control panel.

Note: There are two wires numbered 2. One is for connecting to the 0 VDC in the

main MCS control panel and the other one is for connecting to the blowback

solenoid valve.

5.

Connect wire nut (wire number 2 in drawing) to the 0 VDCconductor located inside the

main MCS control panel.

6.

Connect wire nut (wire number 2 in drawing) to the blowback solenoid located at the

vacuum receiver

7.

Connect wire nut (wire number 4 in drawing) to the blowback solenoid located at the

vacuum receiver.

8.

Connect wire nut (wire number 8 in drawing) to the 24 VDC hot station valve output

requiring blowback.

9.

Connect wire nuts (wire numbers 3, MCSMAT Demand in drawing) in series with the

demand level switch of the station requiring blowback.

BC-1 IM 8 FEB 2018

© 2018 NOVATEC, Inc. All RightsReserved

Page 7

6.0 OPERATION

5.1

Control Description

The BC-1 blowback control is connected to an MCS main control to add a blowback feature,

when required. The BC-1 employs a mini-PLC Control. The control is housed in a rugged

enclosure and is factory programmed for functions related to vacuum loading.

NOTE: The user may adjust certain parameters of the control to fine tune their loader’s

operation, but changing settings other than those listed can damage control operation.

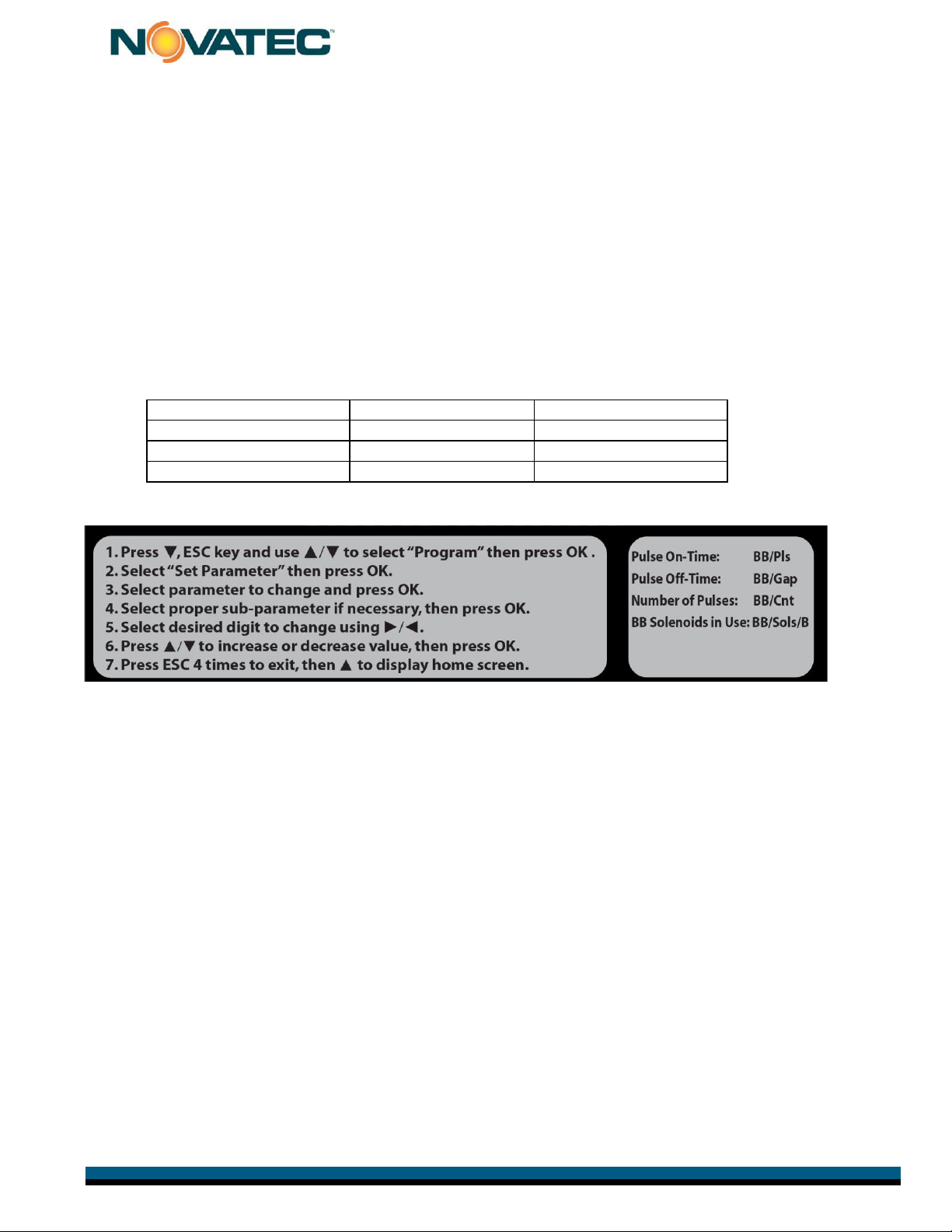

5.2

Preset Controller Values

The BC-1 controller is preset at the factory with the following values.

FUNCTION

TIMER

FACTORY SETTING

Pulse On-Time

BB/Pls

0.5 Seconds

Pulse Off-Time

BB/Gap

1 Seconds

Number of Pulses

BB/Cnt

3 Counts

BB Solenoids in Use

BB/Sols/B

1

5.3

Changing Controller Values

Press the OFF/ON switch for the BLOWBACK CONTROLLER to the “ON” position.

Allow a few seconds for the LOGO! controller to start up.

Using the instruction on the controller under TO CHANGE SETTINGS:

Adjust the number of blowback pulses by changing the BB/Cnt parameter values in the

“Settings” menu of the controller to achieve the desired blowback pulsing for that station.

When the station loading signal is de-energized to the LOGO unit and the OFF/ON switch

is in the ON position, the blowback solenoid will be energized for the number of pulses

set in the BB/Cnt parameter value. Once the blowback cycle is complete, the contact on

the blowback controller wired in series with the station demand level switch would close

allowing the station to begin loading again if the demand level switch were also closed.

The BB/Gap timer controls the OFF time between pulses and the BB/Pls timer controls

the ON time of the pulse, these timers are set at 1.0 and 0.5 seconds respectively and

should not require further adjustment.

7.0 WARRANTY

NOVATEC, INC. offers COMPREHENSIVE PRODUCT WARRANTIES on all

of our plastics auxiliary equipment. We warrant each NOVATEC manufactured

product to be free from defects in materials and workmanship, under normal

use and service for the periods listed under “Warranty Periods”. The

obligation of Novatec, under this warranty, is limited to repairing or

furnishing, without charge, a similar part to replace any part which

fails under normal use due to a material or workmanship defect, within

its respective warranty period. It is the purchaser’s responsibility to

provide Novatec with immediate written notice of any such suspected

defect. Warranted replacement parts are billed and shipped freight

pre-paid. The purchaser must return the suspect defective part, freight

prepaid and with identifying documentation to receive full credit for the

part returned. Novatec shall not be held liable for damages or delay

caused by defects. No allowance will be made for repairs or alterations

without the written consent or approval of Novatec.

The provisions in equipment specifications are descriptive, unless

expressly stated as warranties. The liability of Novatec to the

purchaser, except as to title, arising out of the supplying of the said

equipment, or its use, whether based upon warranty, contract or

negligence, shall not in any case exceed the cost of correcting defects

in the equipment as herein provided. All such liability shall terminate

upon the expiration of said warranty periods. Novatec shall not in

any event be held liable for any special, indirect or consequential

damages. Commodities not manufactured by Novatec are warranted

and guaranteed to Novatec by the original manufacturer and then only

to the extent that Novatec is able to enforce such warranty or

guaranty. Novatec, Inc. has not authorized anyone to make any

warranty or representation other than the warranty contained here.

Non-payment of invoice beyond 90 days will invalidate the warranty. A

renewed warranty can be purchased directly from Novatatec.

Please note that we always strive to satisfy our customers in whatever manner is deemed most expedient to overcome any issues in

connection with our equipment.

Warranty Periods:

Note: All warranty periods commence with the shipment of the equipment to the customer.

5-Year (Except 1-Year on Non-Novatec Buy-Out Items)

Resin Drying to Include

NovaWheel™ Dryers *

Dual Bed Dryers

NovaDrier *

NDM-5 Membrane Dryer

Gas-Fired Process Heaters

Gas-Fired Regeneration Heaters

Drying Hoppers

Central Drying Hopper Assemblies

Heater/Blower Units and Hot-Air Dryer

Silo Dehumidifiers

NovaVac Dryers *

Nitrogen NovaDriers (Nitro)

DryTemp Plus

Resin Blending and Feeding to Include

WSB Blenders, MaxiBatch & Feeders *

Gaylord Sweeper Systems

Downstream Extrusion Equipment to Include

C and NC Bessemer Series Cutters

NPS Bessemer Series Pullers

NPC Mini Puller/Cutter

All NS Series Servo Saws

All Cooling and Vacuum Tanks Manufactured

Central System Controls to Include

FlexTouch™ Series Controls

FlexXpand™ Series Controls

OptiFlex™ Series Controls

PLC Communications Modules

Greenboard Communications Modules

LOGO! Mini PLC

MCS-600 Series Controls – (Distributed I/O)

MCS-400 Series Controls

CL Silo Manager

Moisture Measurement Equipment to Include

MoistureMaster®

PET Resin Crystallizers

Resin Conveying and Systems Components to Include

GSL Series Vacuum Loaders

GlassVu Loaders, Receivers and Hoppers

VL/VLP Series Loaders

VRH, VR, VR-FL & VRP Series Receivers

Compressed Air Loaders

AL-B Barrel Loader

Cyclone Dust Collectors

Conveying System Accessories

Surge Bins

Valves and Accessories

Electronic Metal Separators

Quick Select Manifolds

Tilt Tables

Filter Dust Collectors

Drawer Magnets

Velocity Control Valves

3-Year

Resin Conveying System Components to Include

** VPDB Vacuum Positive Displacement Pumps

** SVP Vacuum Pumps

** MVP Vacuum Pumps

** Railcar Unloading Systems

**5-Year Extended Warranty- When a MachineSense® data plan is activated for products with **, Novatec automatically extends the warranty to 5

years. The data plan must be activated within 60 days after product shipment, and remain active through the warranty period to maintain extended warranty

eligibility. The first 6-months of data plan usage is free from Novatec.

1-Year

Infrared Dryers

UltraVac Vacuum Pumps Vacuum Regenerative Blower Pumps

Custom Equipment of any kind unless otherwise specified

Exclusions:

Routine maintenance/replacement parts are excluded from the warranty. These include, but are not limited to: hoses, desiccant, filters, filter elements,

wiper seals, gaskets, dew point sensors, infrared lamps, motors, internal solenoids, fuses and motor brushes. Use with abrasive materials will void

the warranty of any standard product. Wear resistant options may be available to extend usable service life with abrasive materials. Novatec

reserves the right to limit the warranty if the customer installs replacement parts that do not meet the specifications of the original parts supplied by

Novatec.

*Specific Exclusions:

1. NovaDrier and NovaDrier-Nitro warranty is void if coalescing filters are not replaced on a 6-month or yearly basis (per

instruction manual) and/or membrane has been exposed to ozone.

2. NovaVac Dryer -The ability of the canisters to hold vacuum will be compromised if the vacuum seal edge is damaged

from mishandling. We do not warranty canisters damaged from improper handling. We do, however, warranty the seals.

3. LOAD CELLS on our WSB’s are covered by Novatec standard warranty as long as they have not been damaged from

improper handling.

4. Desiccant Wheel Warranty will be void if the wheel has been exposed to plasticizer, dust or other contaminants as a result

of negligence on the part of the processor.

This warranty shall not apply to equipment:

1. Repaired or altered without written approval of NOVATEC unless such repair or alteration

was, in our judgment, not responsible for the failure

2. Which has been subject to misuse, negligence, accident or incorrect wiring by others

3. Warranty is void if processing rates exceed manufacturer-recommended levels or if damage is caused by

ineffective power isolation and/or power spikes/sags or incorrect installation.

NOTE: All conditions and content of this warranty are subject to changes without notice.

Exclusions:

Routine maintenance/replacement parts are excluded from the warranty. These include, but are not limited to: hoses, desiccant, filters,

filter elements, wiper seals, gaskets, dew point sensors, infrared lamps, motors, internal solenoids, fuses and motor brushes. Use with

abrasive materials will void the warrantyof any standard product. Wear resistant optionsmay be available to extend usable service life

with abrasive materials. Novatec reserves the right to limit the warranty if the customer installs replacement parts that do not meet the

specifications of the original parts supplied byNovatec.

*Specific Exclusions:

1.

NovaDrierwarrantyisvoidifcoalescingfiltersarenotreplacedona6-monthoryearlybasis(perinstructionmanual)

and/or membrane has been exposed to ozone.

2.

NovaVacDryer-Theabilityofthecanisterstoholdvacuumwillbecompromisedifthevacuumsealedgeisdamaged

frommishandling.Wedonotwarrantycanistersdamagedfromimproperhandling.Wedo,however,warrantytheseals.

3.

LOADCELLSonourWSB’sarecoveredbyNovatecstandardwarrantyaslongastheyhavenotbeendamagedfrom

improper handling.

4.

DesiccantWheelWarrantywillbe void ifthewheelhas beenexposedto plasticizer,dust or othercontaminantsasa

result

of negligence on the part of the processor.

This warranty shall not apply to equipment:

1.

Repaired or altered without written approval of NOVATEC unless such repair or

alteration was, in our judgment, not responsible for thefailure

2.

Which has been subject to misuse, negligence, accident or incorrect wiring byothers

3.

Warranty is void if processing rates exceed manufacturer-recommended levels or if damage is caused by

ineffective power isolation and/or power spikes/sags or incorrectinstallation.

NOTE: All conditions and content of this warranty are subject to changes without notice.

BC-1 IM 31 OCT 2017 © 2017 NOVATEC, Inc. AllRights Reserved Page 8

This manual suits for next models

2

Table of contents