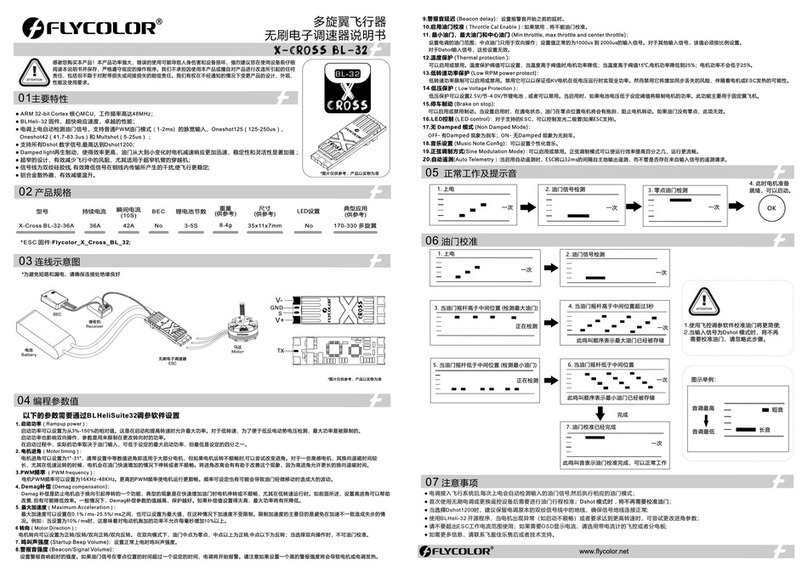

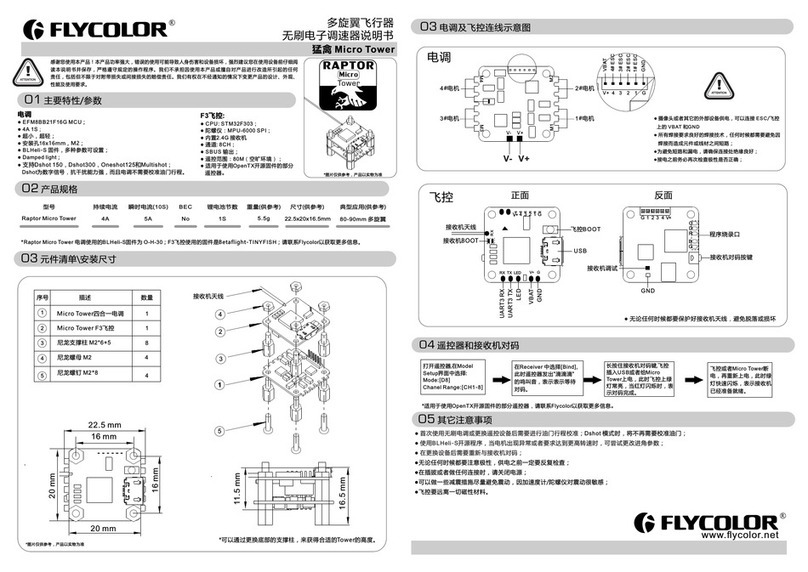

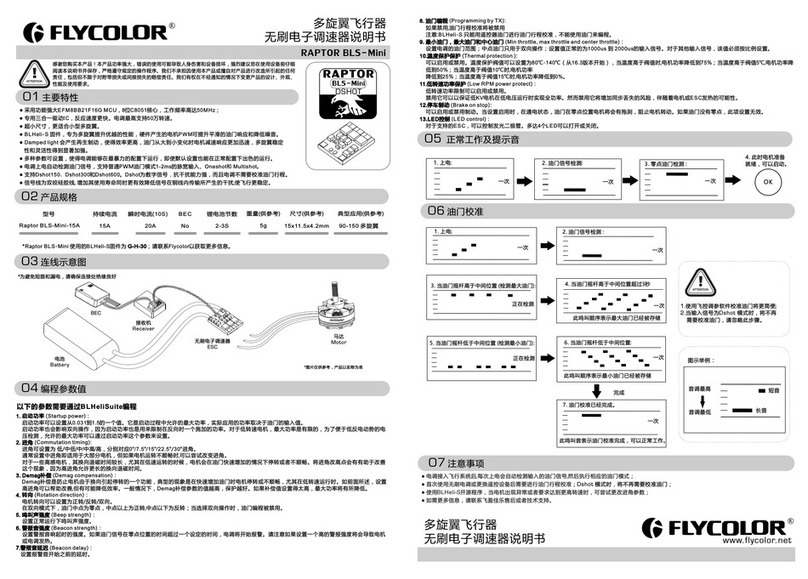

05 ESC Programming parameter

www.flycolor.net

251400-1062,V 1.0

06 Attention

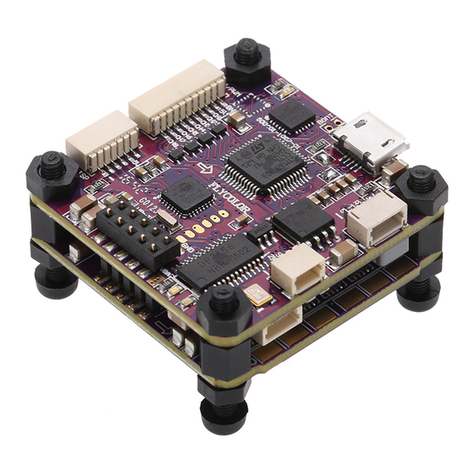

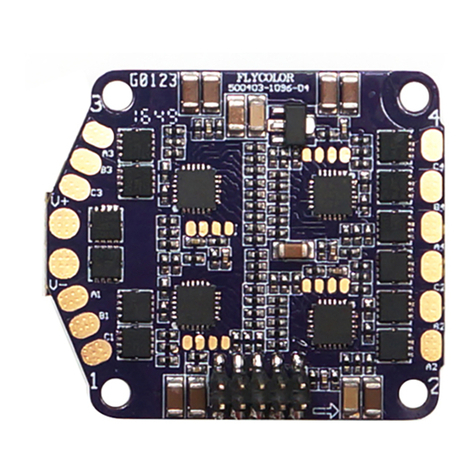

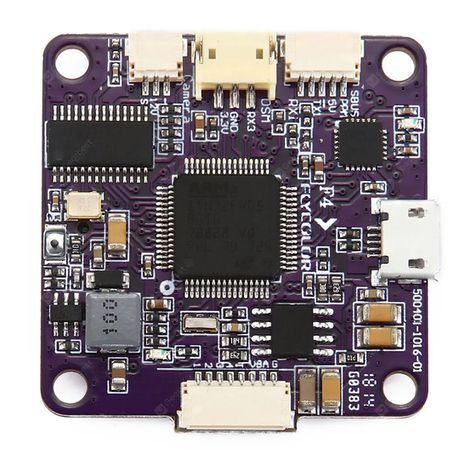

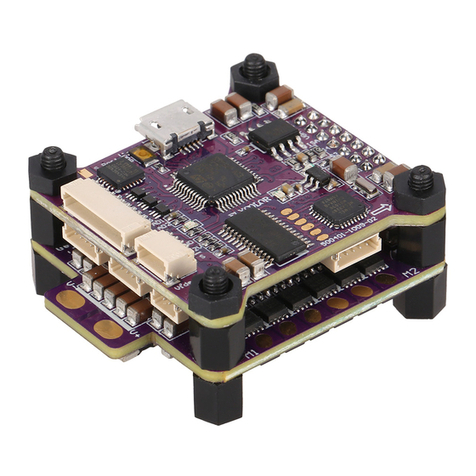

TOP

GND

5V

1

2

3

4

5

6

AD1

AD2

GND

12V

S

S.Port

BOOT

AD2

RSSI

Video

PPM/PWM

Press “BOOT” for recovering firmware

Smart Port Pad

GND

Vin

GND

VIDEO

GND

12V

S

Image

transmitter

GND

5V

CH1

PPM

Receiver

GND

5V

1

12V

Camera

S

12V

GND

3

2

1

ISP programming (OSD Debug)

5V

LED

5V

Buz -

RX

TX

5V

LED

GND

5V

LED

Buzzer

5V

Buzzer

1

2

3

4

5

S

12V

Camera

SBUS

ISP

T

X R

X

D

T

R 5

V

G

N

D

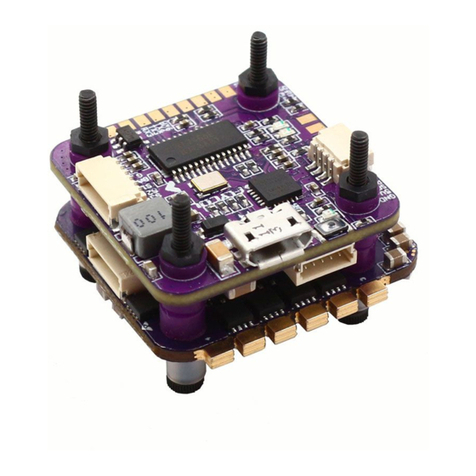

BOTTOM

UART3

RX

TX

5V

GND

12V

Camera

S

12V

GND

3

2

1

ISP programming (OSD Debug)

5V

LED

5V

Buz -

RX

TX

5V

LED

GND

5V

LED

Buzzer

5V

Buzzer

1

2

3

4

5

S

12V

Camera

SBUS

ISP

T

X R

X

D

T

R 5

V

G

N

D

BOTTOM

UART3

RX

TX

5V

GND

TOP

GND

5V

1

2

3

4

5

6

AD1

AD2

GND

12V

S

S.Port

BOOT

Video

PPM/PWM

Press “BOOT” for recovering firmware

Smart Port Pad

GND

Vin

GND

VIDEO

GND

12V

S

Image

transmitter

PWM

Receiver

GND

5V

CH1

CH2

CH3

CH4

CH5

CH6

GND

5V

1

2

3

4

5

6

AD2

RSSI

PPM Mode

PWM Mode

1. Startup power:

Startup power can be set to relative values from 0.031 to 1.5. This is the maximum power that is allowed during startup. Actual applied power depends on throttle input, and

can be lower, but the minimum level is a quarter of the maximum level. Startup power also affects bidirectional operation, as the parameter is used to limit the power applied

during direction reversal. For low rpms, the maximum power to the motor is limited, in order to facilitate detection of low BEMF voltages. The maximum power allowed can be

set via the startup power parameter.

2. Commutation timing:

Commutation timing can be set to low/mediumlow/medium/mediumhigh/high, that correspond to 0°/7.5°/15°/22.5°/30° timing advance.

Typically a medium setting will work fine, but if the motor stutters it can be beneficial to change timing. Some motors with high inductance can have a very long commutation

demagnetization time. This can result in motor stop or stutter upon quick throttle increase, particularly when running at a low rpm. Setting timing to high will allow more time for

demagnetization, and often helps.

3. Demag compensation:

Demag compensation is a feature to protect from motor stalls caused by long winding demagnetization time after commutation. The typical symptom is motor stop or stutter

upon quick throttle increase, particularly when running at a low rpm. As mentioned above, setting high commutation timing normally helps, but at the cost of efficiency.

Generally, a higher value of the compensation parameter gives better protection. If demag compensation is set too high, maximum power can be somewhat reduced.

4. Direction:

Rotation direction can be set to fwd/rev/bidirectional fwd/bidirectional rev. In bidirectional mode, center throttle is zero and above is fwd rotation and below is reverse rotation.

When bidirectional operation is selected, programming by TX is disabled.

5. Beep strength:

Sets the strength of beeps under normal operation.

6. Beacon strength:

Sets the strength of beeps when beeping beacon beeps. The E S C will start beeping beacon beeps if the throttle signal has been zero for a given time. Note that setting a high

beacon strength can cause hot motors or ESCs!

7. Beacon delay:

Beacon delay sets the delay before beacon beeping starts.

8. Programming by TX: If disabled, throttle calibration is disabled.

Please notice that throttle stick can calibrate throttle range only, and can not programming paramenter via throttle stick .

9. Min throttle, max throttle and center throttle:

These settings set the throttle range of the E S C. Center throttle is only used for bidirectional operation. The values given for these settings are for a normal 1000us to 2000us

input signal, and for the other input signals, the values must be scaled.

10.Thermal protection:

Thermal protection can be enabled or disabled. And the temperature threshold can be programmed between 80°C and 140°C(from rev16.3).

The E S C measures temperature within the MCU and limits motor power if the temperature is too high. Motor power is limited in four steps:

- If the temperature is above threshold , motor power is limited to 75%.

- If the temperature is above threshold 5°C, motor power is limited to 50%.

- If the temperature is above threshold 10°C, motor power is limited to 25%.

- If the temperature is above threshold 15°C, motor power is limited to 0%.

11.Low RPM power protect:

Power limiting for low RP Ms can be enabled or disabled. Disabling it can be necessary in order to achieve full power on some low kV motors running on a low supply voltage.

However, disabling it increases the risk of sync loss, with the possibility of toasting motor or ESC.

12.Brake on stop:

Brake on stop can be enabled or disabled. When enabled, brake will be applied when throttle is zero. For nonzero throttle, this setting has no effect.

Programming parameters below can be accessed from the configuration software (BLHeliSuite):

● User need to calibrate the throttle range when starting to use a new ESC or another transmitter. When the input signal is Dshot, throttle calibration is disabled

● BLHeli-S open-source firmware, when some abnormality occurs in ES C driving the motor or need the motor to reach a higher RP M, user can try to change the timing.

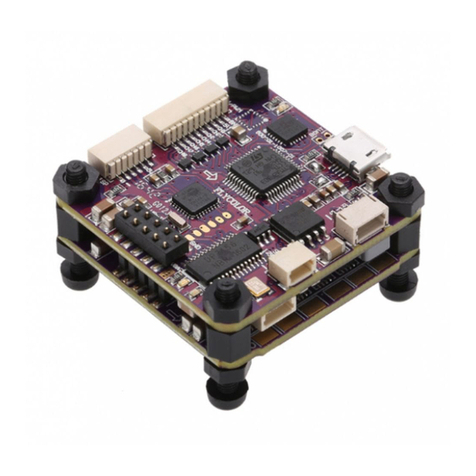

● Observe polarity at all times. Check and double check before applying power. ● Power off before unplugging ,plugging in or making any connections.

● 5V ,12Vsupply is for low-current use only(5V 1A MAX, 12V 500mA MAX). ● Keep magnets away from the Flight Controller.

● Do everything you can to prevent vibrations. ● Please contact Flycolor sales or technical support for more information.

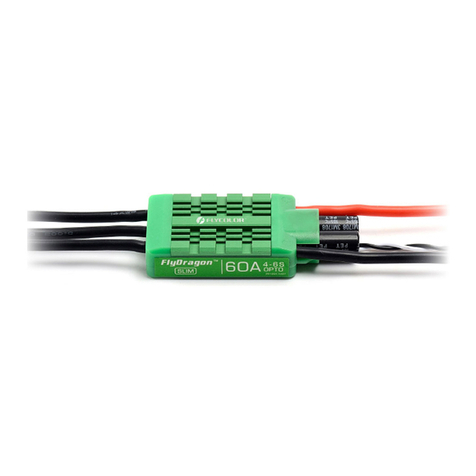

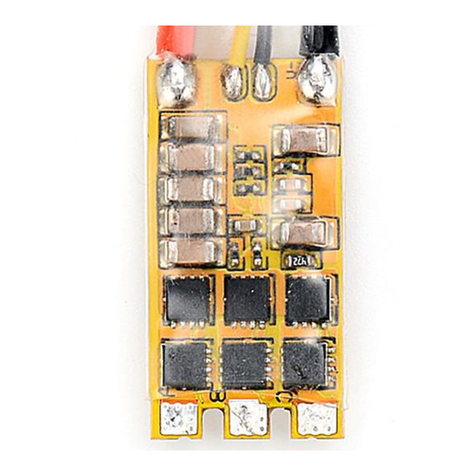

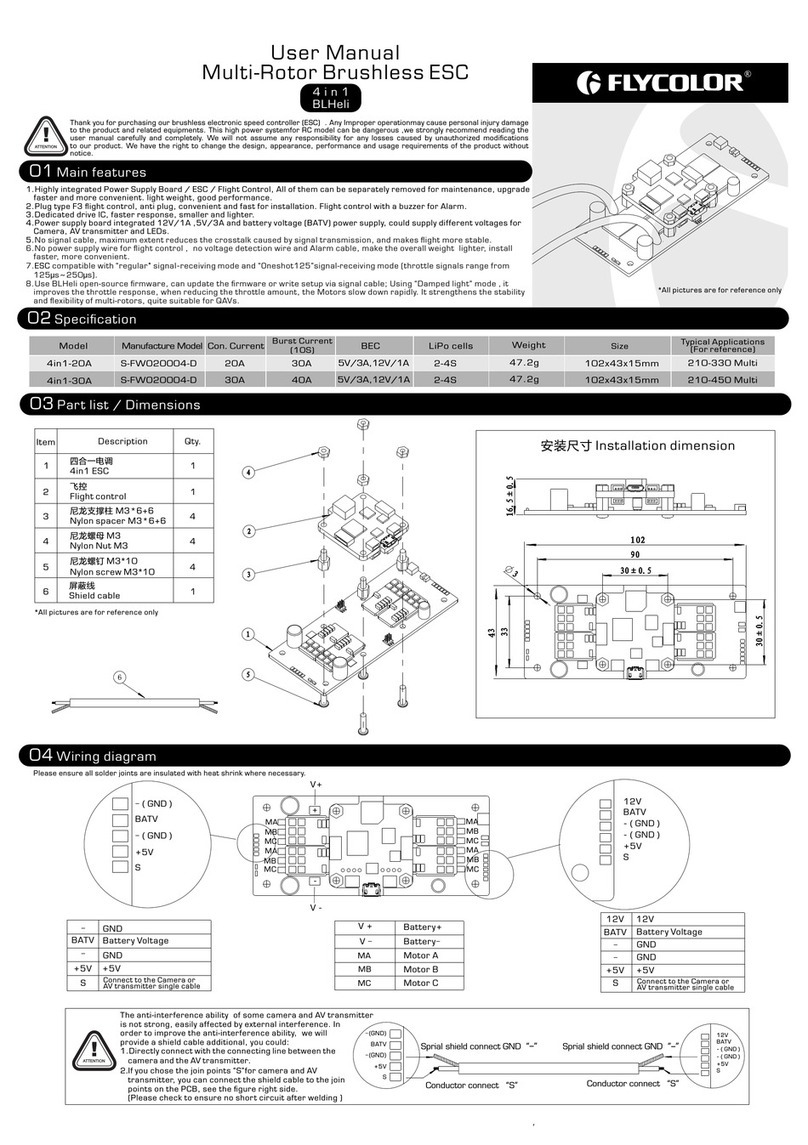

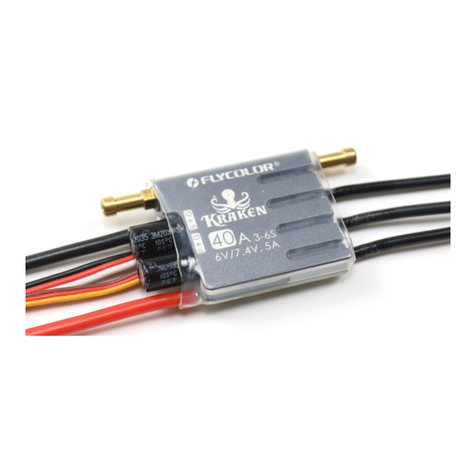

User Manual

Multi-Rotor Brushless ESC