2. DESCRIPTION

1 2

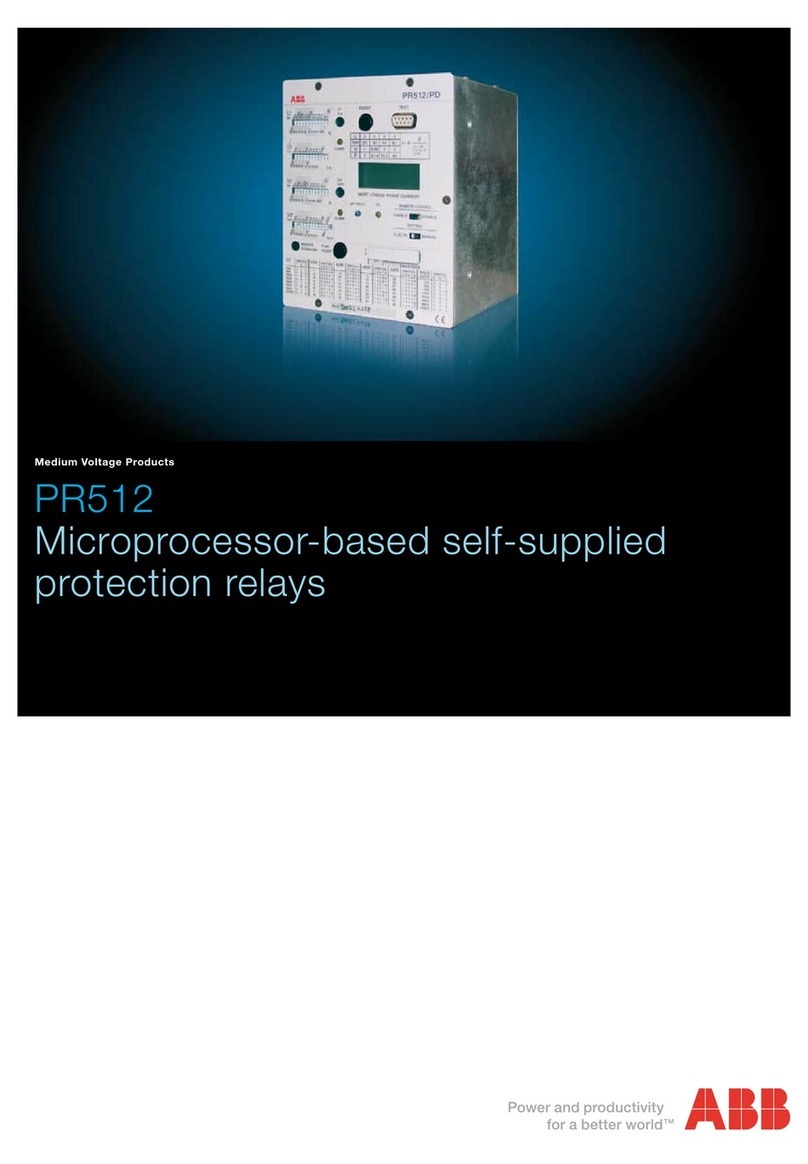

The RNPP-301 relay (hereafter “the relay”) is a digital microprocessor device that provides a high degree of

reliability and accuracy. The relay doesn’t require any auxiliary power supply because it is self-powered by the

three-phase voltage to be monitored. This permits the relay to keep operate capability even when only one

phase is present (in the three-phase systems with neutral). Two modes of the mains voltage monitoring can

be selected at the user’s option:

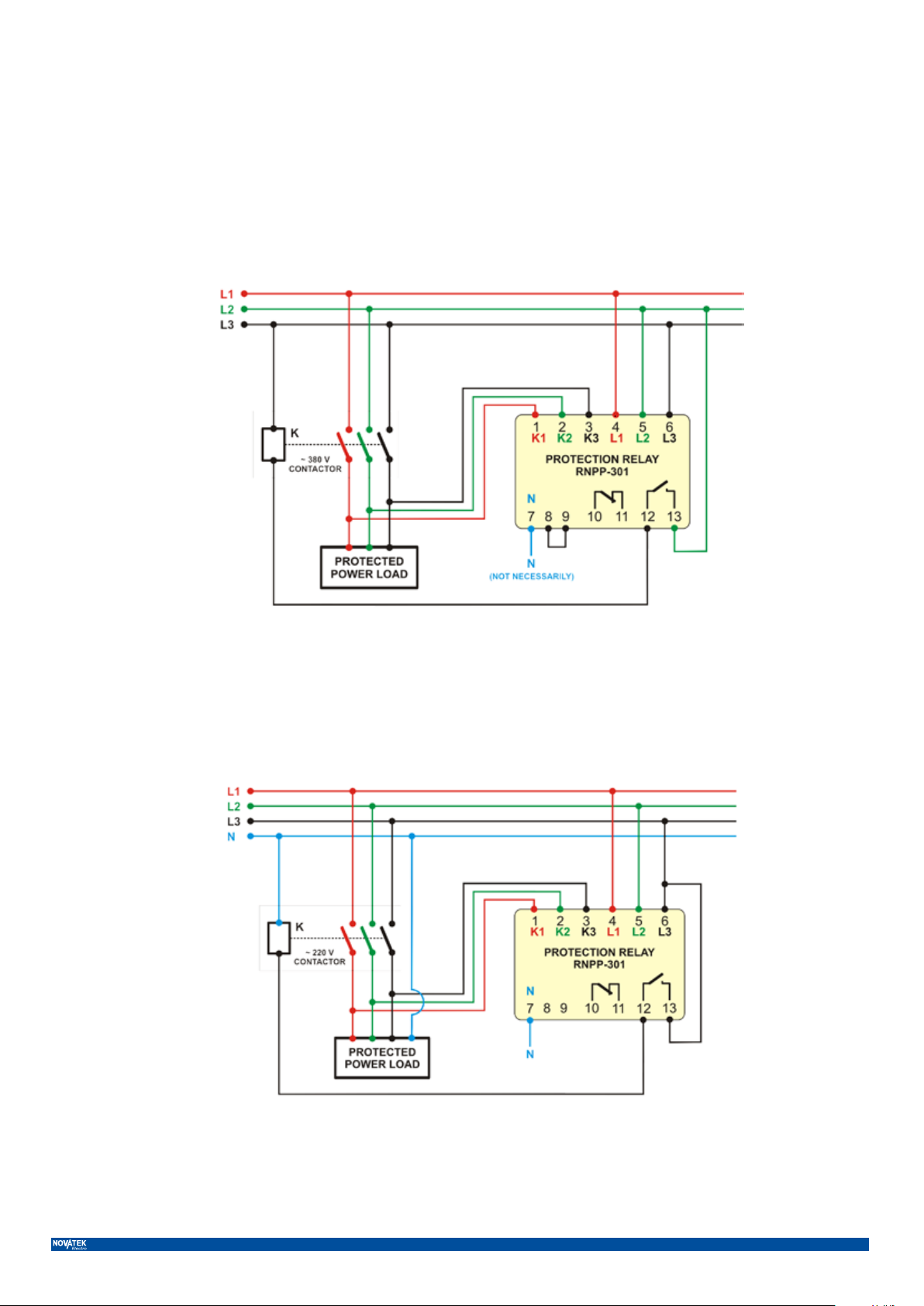

The line voltage monitoring mode.

To go into this mode of operation one needs to apply the jumper strap between terminals 8-9; in this case to

connect the neutral is not necessary. This mode of operation is recommended when the neutral drift value and

phase voltage imbalance is not important as well as for isolated neutral three-phase systems. The relay will

trip when line voltage imbalance between phases occurs.

Note:To keep the relay operative and informative when only one phase is present it’s advisable to connect the

neutral to the terminal 7 not removing the jumper strap between terminals 8-9. In 3-Phase systems without

neutral the relay keeps operational capability when at least two phases are present.

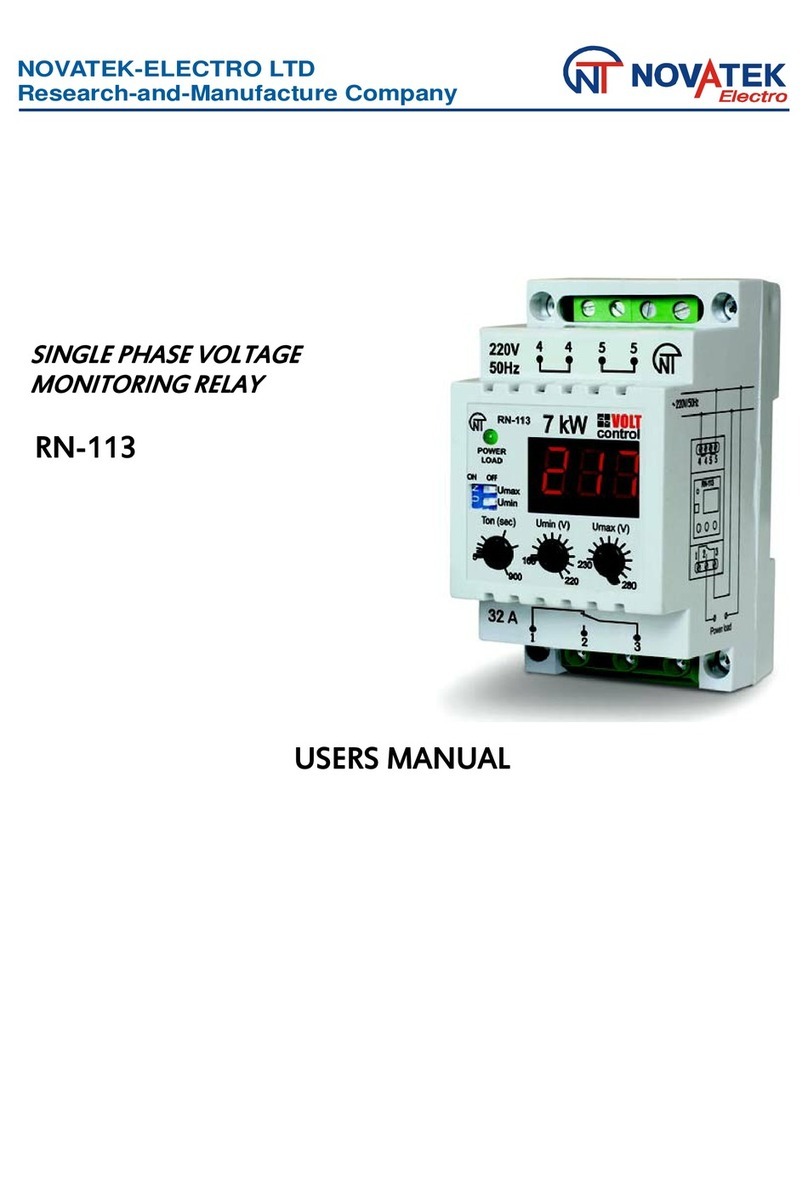

The relay is connected in parallel to load by the L1, L2, L3 input contacts (the 4, 5, 6 terminals respectively).

The neutral connection mode (N, the 7 terminal) corresponds to the mains voltage monitoring mode of

operation selected by user. The 1, 2, 3 terminals provide the MS power contacts status monitoring and are

connected to the output MS power contacts terminals (see the wiring diagram). The relay has two groups of

independent output contacts (10-11, 12-13). In the “dead status” of the relay (a voltage is not applied to the

relay, the relay is not connected) the 12-13 are the N.O. contacts and the 10-11 are N.C. contacts. After the

relay has been connected in parallel to load when voltage is present in the mains and there is no cause for the

relay to trip, the 12-13 contacts are being closed and the 10-11 contacts are being opened with the user-set

reset delay Ton.

It is recommended the 12-13 contacts to connect in series with the MS coil power supply.

When the relay tripped, load is de-energized due to the break in the MS coil power curcuit by the N. O. 12-13

contacts

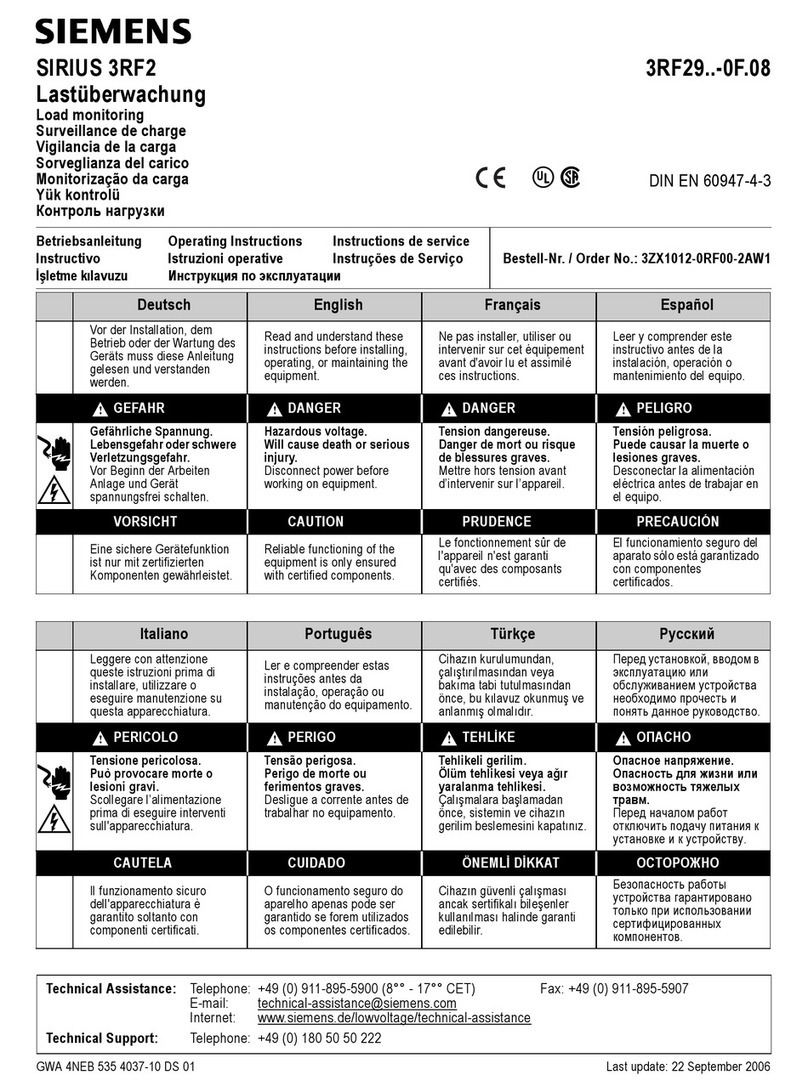

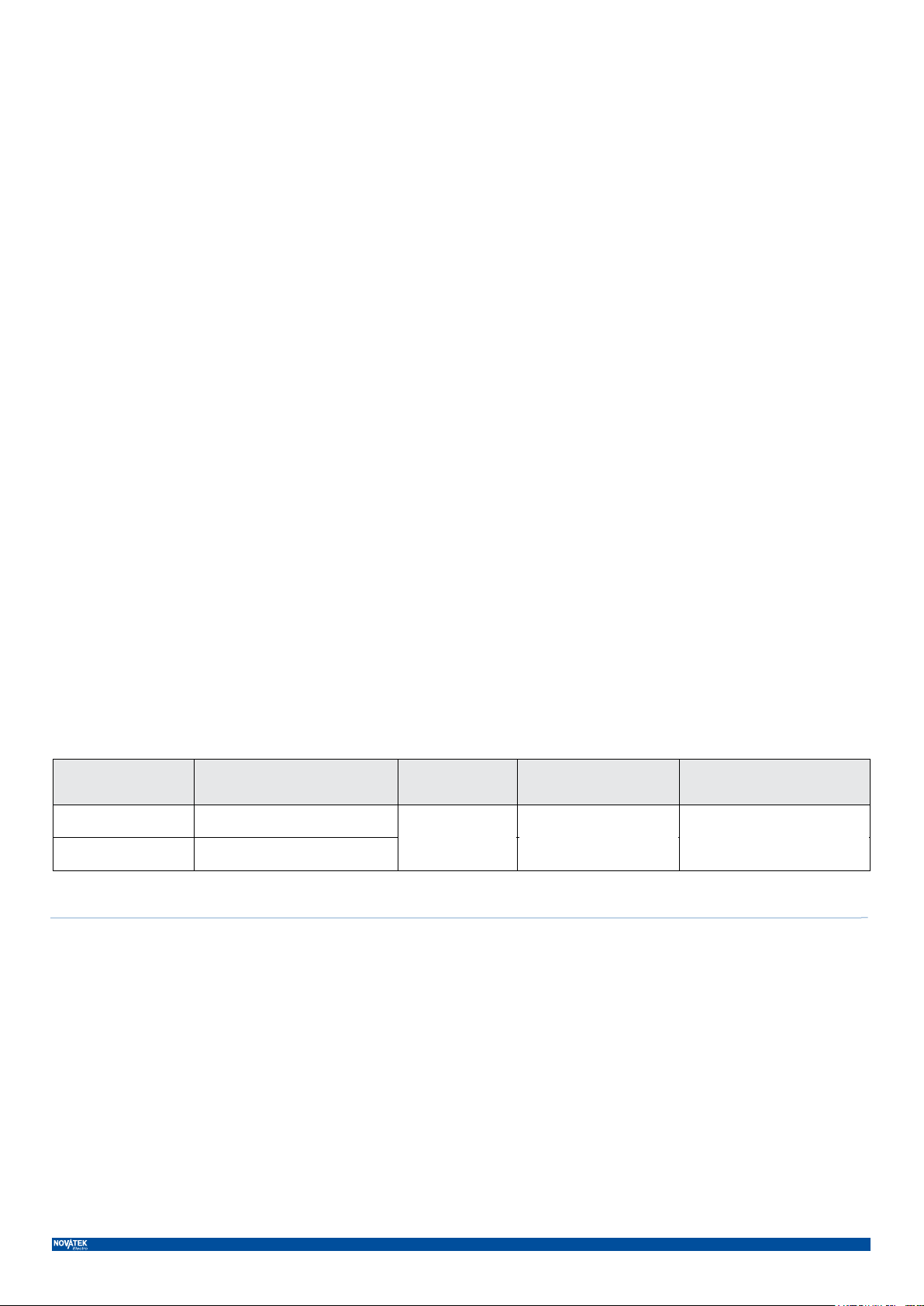

THE 10-11, 12-13 OUTPUT CONTACTS SPECIFICATION

Max. current for

~ 250 V A. C. Max. power Max sustained

safe voltage ~

Max. current for

U = 30V D.C.

Cosφ = 0.4 3A

Cosφ = 1.0 5A

2000VA 460V 3V

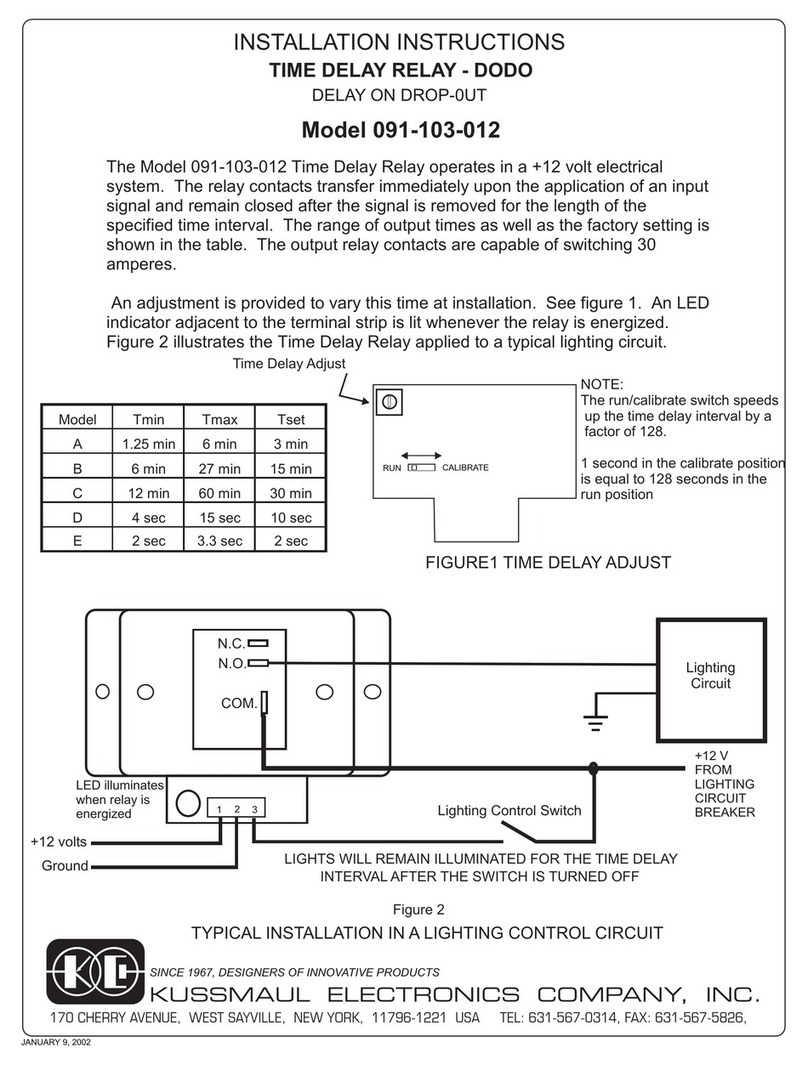

One of the relay functions is the monitoring of the MS power contacts position before load energization and

after load is energized. The monitoring is performed if the1, 2, 3 terminals are connected to the corresponding

phases of the MS output contacts. The monitoring is performed as follows:

Before load is energized a test for open position of all three MS power contacts is performed. If at least•

one contact is closed (“sticks”) the relay will be disabled, the load is not energized, all red “FAULT” LEDs

are ON. To enable the relay one needs to remove supply voltage from it. It’s recommended to test the MS

running order, following safety regulations.

When load is energized, the test for closed position of all three MS power contacts is performed. If at least•

one MS phase contact is open, the relay will trip to de-energize load and will be disabled. All red “FAULT”

LEDs are ON. To enable the relay one needs to remove supply voltage from it. It’s recommended to test

the MS running order, following safety regulations.

MS POWER CONTACTS TRANSFER MONITORING