Novatek-electro TK-415 User manual

“NOVATEK-ELECTRO” LTD.

Sequential and Combination Timer TK-415

with RS-232 communication

OPERATION MANUAL

WWW.NOVATEK-ELECTRO.COM/EN

2011

www.novatek-electro.in

15 channel Traffic Controller TK-415

Sequential cum Combination timer TK-415

2

1. GENERAL PROVISIONS

1.1. BASIC FUNCTIONS

- microprocessor controlled.

- simple change-over between sequential and combination timer.

- 7-segment LED indications.

- selectable 3 time ranges (SEC:MSEC, MIN:SEC, HRS:MIN)

- cascade connection of several devices for extended total number of channels.

- memorization of program and device mode after switching off and program operation restart

from point of stoppage.

- inputs for timer start and pause control.

- fast resetting.

- copy of settings.

- program can be executed only one time or/and cyclic operation possible.

- RS-232 communication port for programming and possibility of operation through PC/ DCS

(free PC software).

1.2. BASIC TECHNICAL BRIEF

Table 1.1.

Supply voltage, V

85 to 270 AC/DC

Frequency range, Hz

47-63

Power consumption, VA

8

Time setting range

From 100ms to

99hr59min.

Commutation accuracy

±0.1% + 20ms

Number of channels

15

Number of combinations per channel (ON/OFF)

8

Operating temperature range, °C

from -25 through +55

Storage temperature, °С

from -35 through +80

Humidity (non condensing)

95% @ 40°С

Insulation resistance

>100МOhm @ 500V

DC

Dimensions, mm

85.8 х 156.2 х 56.8

Indication of load relay

Yes

Protection level

ІР20

Climatic resistance version

УХЛ4

Data memory, years, minimum

10

Output Relays, CO

15

Channel contacts type

normally open

contact (NO)

3

Characteristics of output channels

сos ϕ

Maximum current at

U~250V

Maximum capacity

Maximum current at

Uconst=24V

1.0

10 A

2500 VA

10 A

0.4

4 A

1000 VA

Commutation resource of output contacts:

- mechanical resource

- electric resource 10A 250V AC, times, minimum

- electric resource 10A 24V DC, times, minimum

- electric resource 4A 250V AC (сos ϕ = 0,4 ), times, minimum

107

100 000

30 000

100 000

Signal «Start»

Contact Closure S1

and S2 maximum at

150 milliseconds

Mounting

onto standard 35 mm

DIN-rail

Mounting position

any

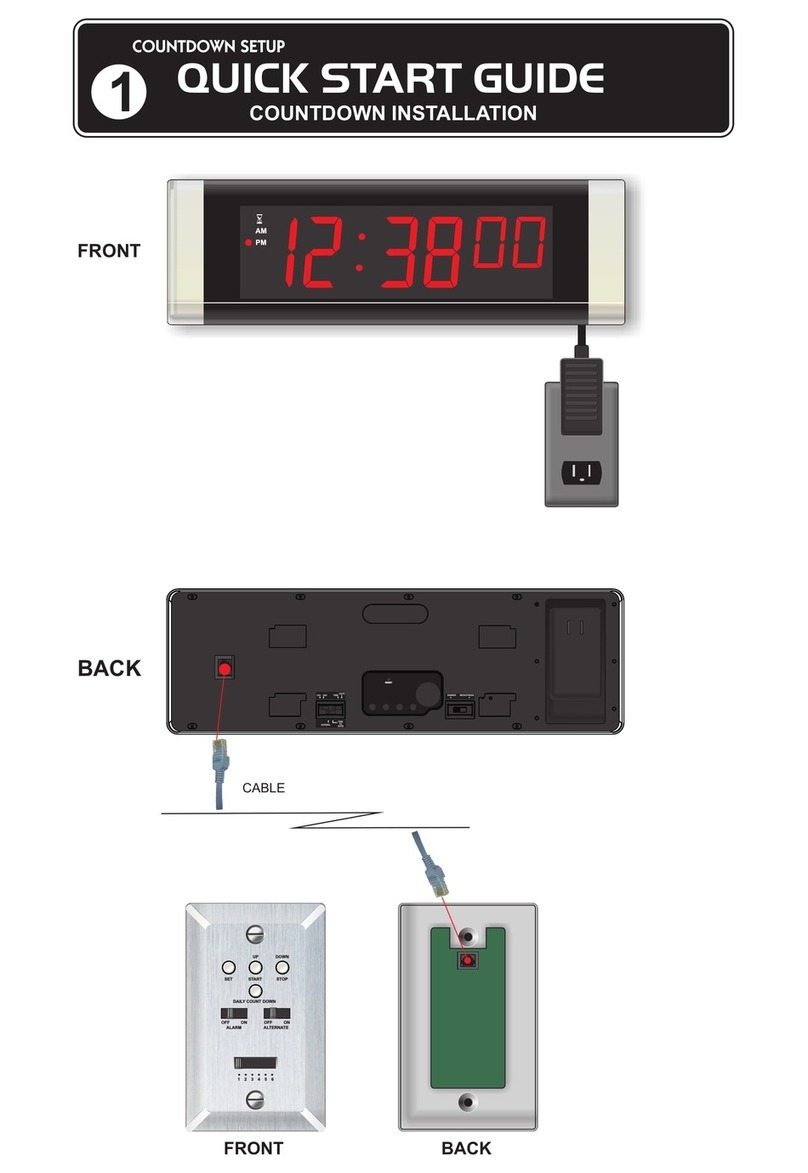

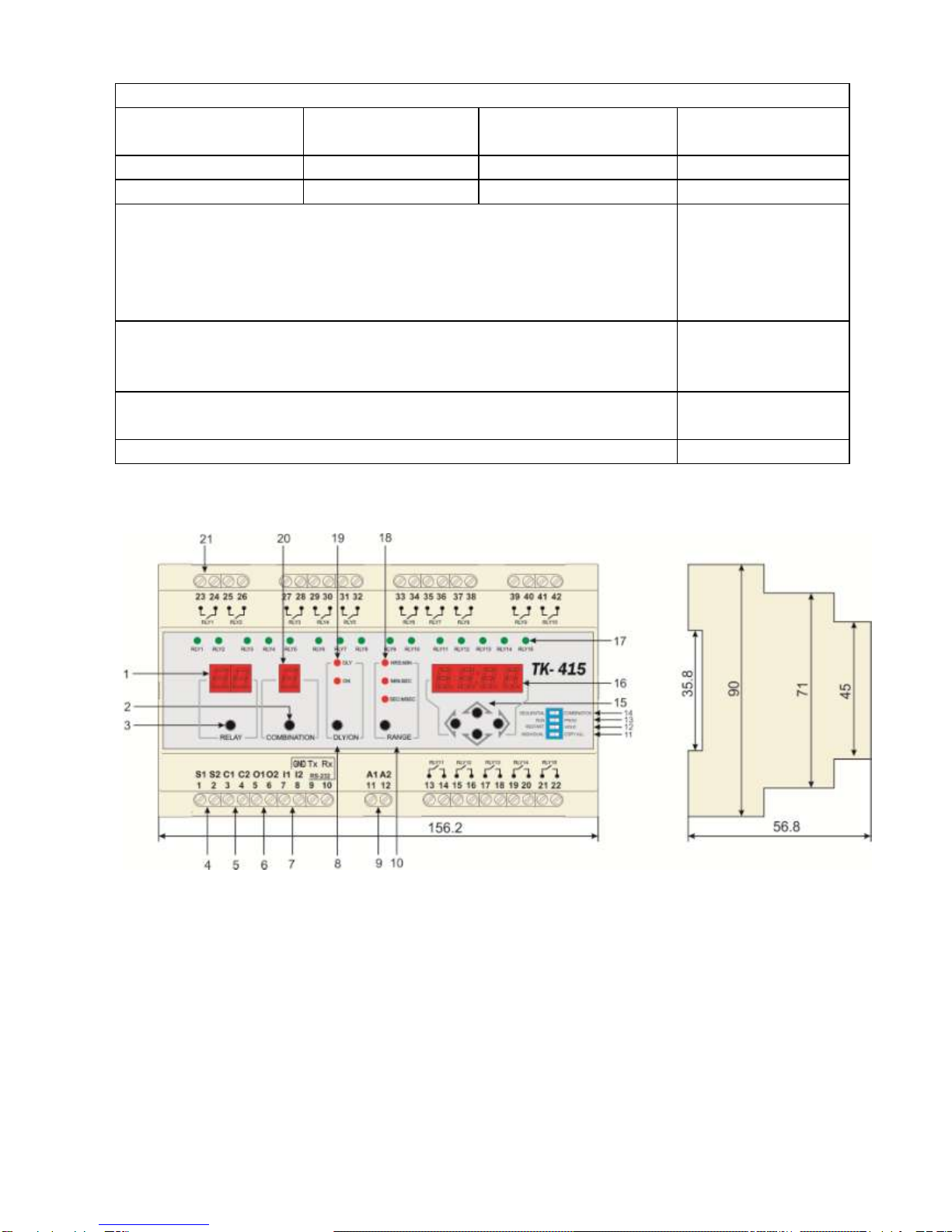

1.3. EXTERNAL VIEW AND DIMENSIONS

Figure 1.1.

1. Indicator for selected channel.

2. COMBINATION

Button of selection of combination DLY/ON of active channel in case of timer operation in

combination mode.

3. RELAY

Button of selection of channel for programming or channel information displaying.

4

4. S1/S2

Inputs of timer start for program execution. For start of program processing inputs S1 and S2

should be closed for 150 milliseconds. Switch RUN/PROG should be in position RUN.

5. C1/C2

Inputs of looping execution of program. If inputs C1 and C2 are closed, the program is executed

only one time. Otherwise, the program would be in cyclic mode.

6. O1/O2

Outputs of cascade connections of devices. After completion of execution of program outputs O1

and O2 are closed for 200 milliseconds.

7. I1/I2

Inputs of pause control. Zero potential between I1 and I2 suspends the program execution. After

un-shorting between I1 and I2, the execution of program is continued from the suspension time.

8. DLY/ON

Button of selection of time setting of open (DLY) or closed (ON) contacts of active channel

output.

9. A1/A2

Power inputs according to technical specifications.

10. RANGE

Button for selection of range of time programming DLY/ON according to the Table 1.2:

Table 1.2

Designation

Range

HRS:MIN

from 1 minute to 99 hours 59 minutes

MIN:SEC

from 1 second to 99 minutes 59 seconds

SEC:MSEC

from 100 millisecond to 999.9 seconds

11. INDIVID/COPY ALL

When the switch is in position INDIVID, the program will be executed for every channel

independently as it have programmed. If switch is in position COPY, during execution of the

program the values of times DLY and ON for every channel will be used from first channel.

12. RESTR/HOLD

Selection of device behavior in case of absence of external power. If the switch is in position

RESTR, the program will restart from the very beginning after restoration of power supply. If it

is in position HOLD, the timer settings at the moment of emergency switching will be stored in

nonvolatile memory and the program will be restarted after restoration of power supply.

13. RUN/PROG

The selection of PROGRAM or RUN timer mode.

5

14. SEQ/COMB

Selection of timer principle of operation: sequential or combination.

15. Buttons for selection of position and setting of values on Time indicator 16.

16. Time Indicator.

17. Indicator displaying closed/open mode of channel contacts.

18. Indicator of selected time range (see Table1.2).

19. Indicator displaying current mode of time programming of open (DLY) or closed (ON) contacts

on Time indicator.

20. Indicator of selected combination for combination timer.

21. Terminals for load connection to output channel contacts.

1.4. TIME DIAGRAMS

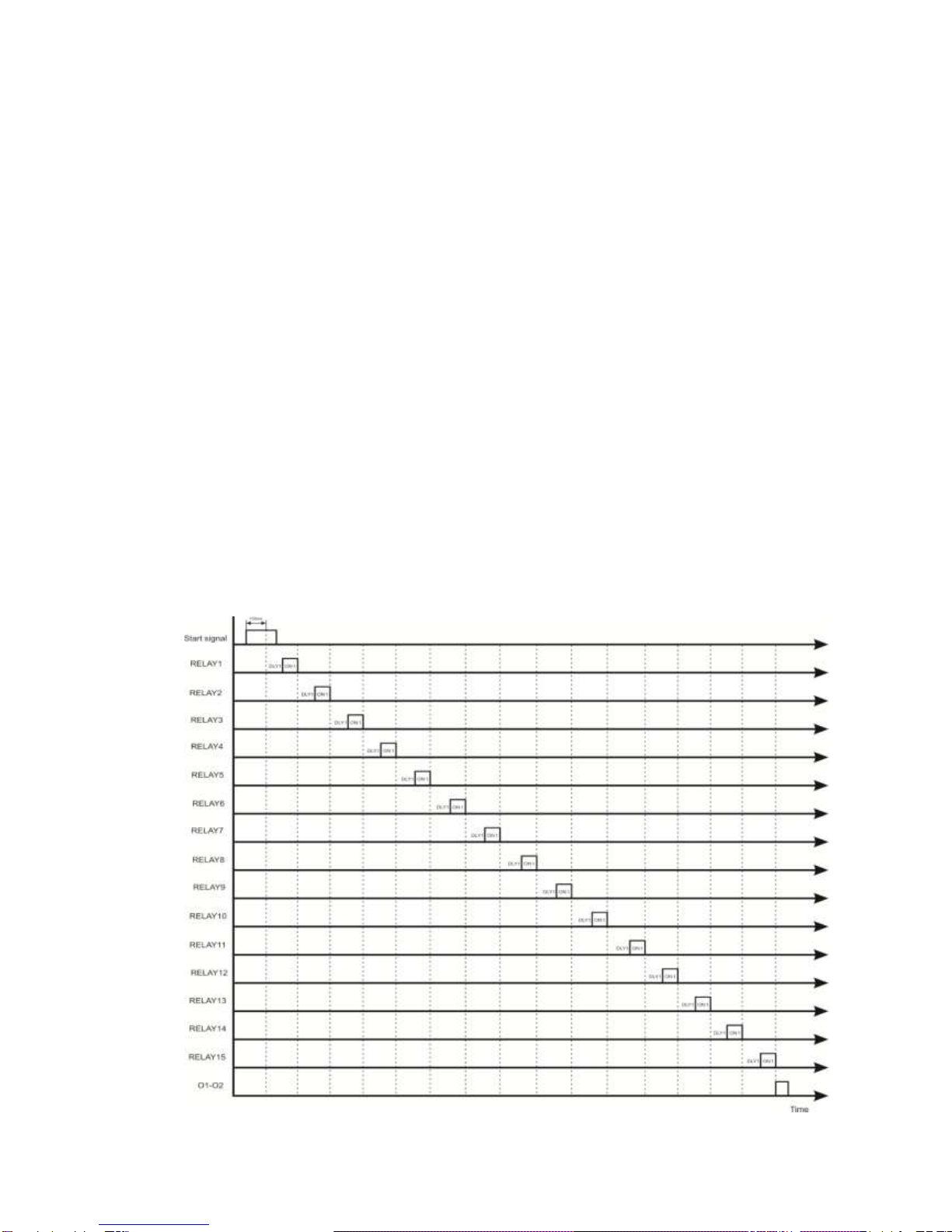

I. Sequential timer, mode of execution of one cycle of program (inputs C1 and C2 are shorted):

Diagram 1.1.

6

II. Sequential timer, cycling mode (inputs C1 and C2 are not shorted):

Diagram 1.2.

7

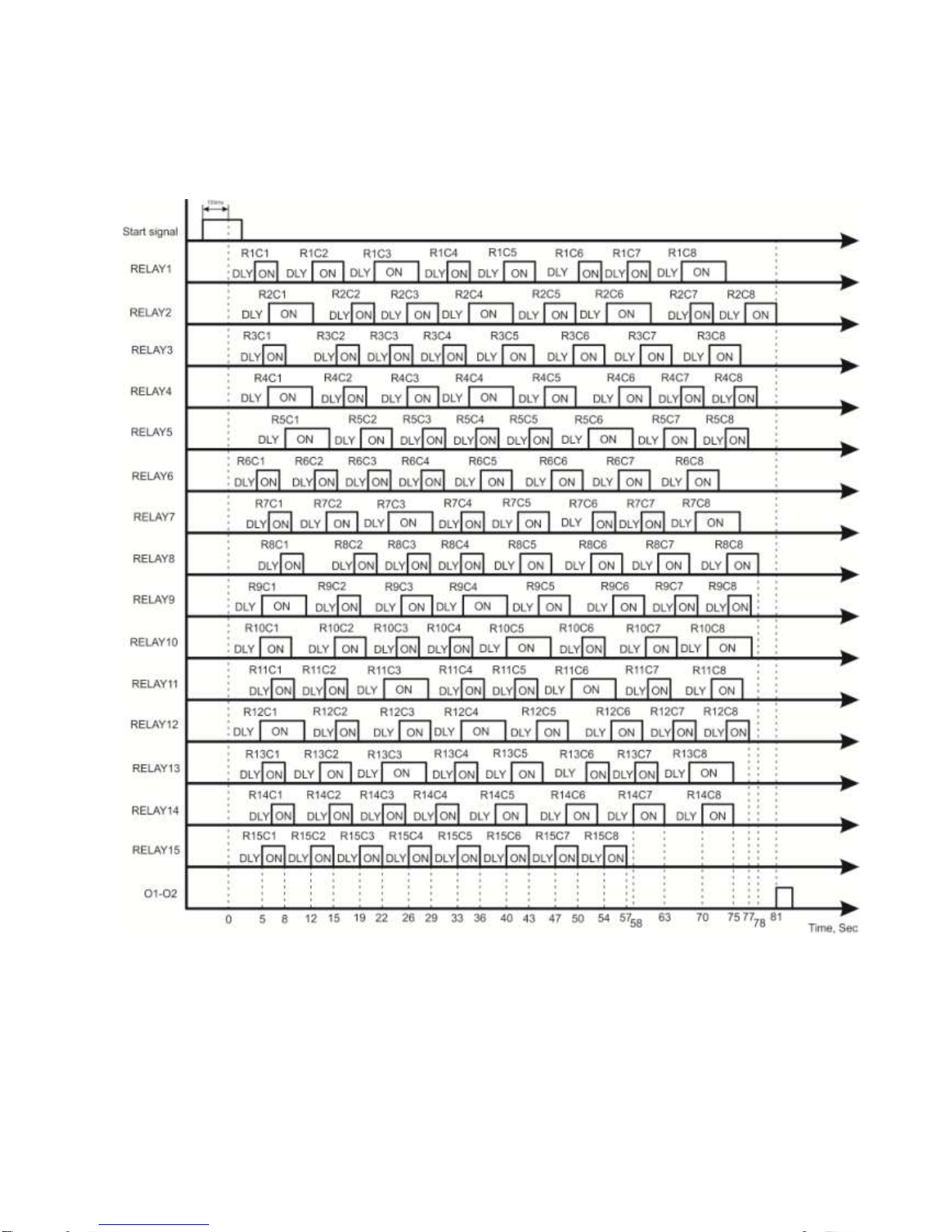

III. Combination timer, mode of execution of one cycle of program (inputs C1 and C2 are

shorted):

Diagram 1.3.

Where, for example, R2C5 means the fifth combination of the second channel (relay).

8

IV. Combination timer, cycle mode (inputs C1 and C2 are not shorted):

Diagram 1.4.

9

2. SETTING AND OPERATION

2.1. CONNECTION

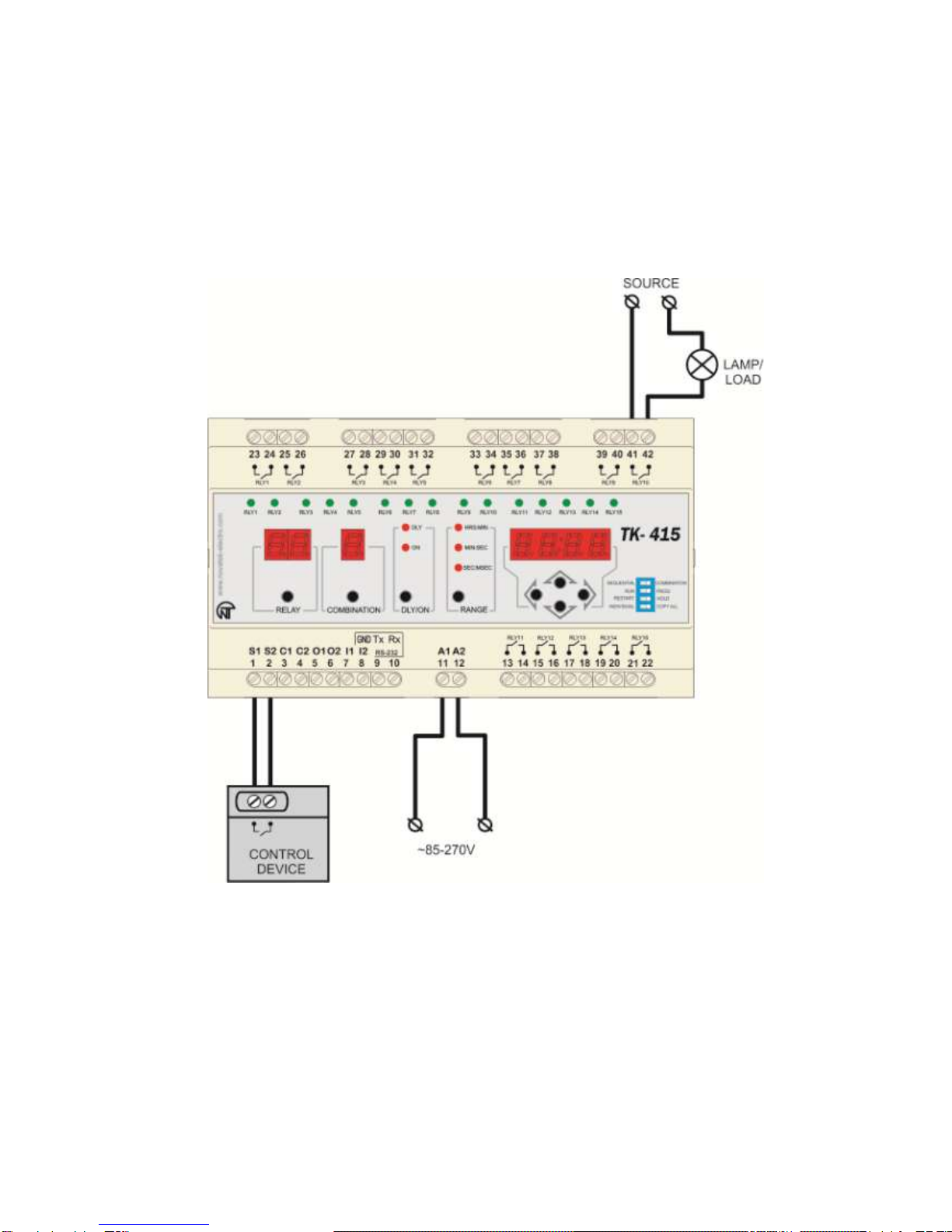

The Figure 2.1 represents the typical method of timer connection. Load is connected to output of

channel RLY10 as an example.

Figure 2.1. Typical method of timer connection.

10

The Figure 2.2 represents the method of cascade connection of three timers. Please, pay attention

that inputs C1 and С2 are shorted.

Figure 2.2. Cascade connection of timers.

Method of cascade connection of timers with possibility of cycle work (upon completion of

operation of last timer the first one starts operating) is represented at Figure 2.3:

Figure 2.3. Cycle operation of timers in case of cascade connection.

2.2. SAFETY MEASURES

ATTENTION! Connection of inputs S1/S2, C1/C2, I1/I2, to external power sources may cause

failure of device. These inputs should be connected only to insulated contacts of relay or switches.

11

2.3. TIMER PROGRAMMING

2.3.1. SEQUENTIAL TIMER PROGRAMMING

1. Fix switch RUN/PROG in position PROG.

2. For sequential timer selection fix switch SEQ/COMB in position SEQ. Supply power to

inputs A1 and A2.

3. Using the button RELAY select the channel 1.

4. Using the button DLY/ON select time DLY for time setting, during which the contacts of

channel relay will be open.

5. Press RANGE for selection of necessary time range.

6. Using arrow buttons set the necessary time.

7. Repeat steps 4 through 6 for status time setting ON, during which the contacts of channel

relay will be closed.

8. Repeat steps 3 through 7 for setting of other channels.

2.3.1. COMBINATION TIMER PROGRAMMING

1. Fix switch RUN/PROG in position «PROG».

2. For selection of combination timer fix switch SEQ/COMB in position COMB. Energize

the inputs A1 and A2.

3. Using button RELAY select channel 1.

4. Using button COMBINATION select combination 1.

5. Using button DLY/ON select time DLY for time setting, during which the contacts of

channel relay will be open.

6. Press RANGE for selection of necessary time range.

7. Using arrow buttons set the necessary time.

8. Repeat steps 5 through 7 for set of status ON, during which contacts of channel relay will

be closed.

9. Repeat steps 4 through 8 for setting the other channel combinations.

10. Repeat steps 3 through 9 for setting of other channels and their combinations.

2.4. TIMER START

1. Fix the switch RUN/PROG in position RUN. Energize inputs A1 and A2.

2. Closure of contacts S1 and S2 on the front panel for at least 150 milliseconds causes

execution of set program by the timer.

3. Execution of program is started from the first channel (first combination) and position of

contacts OFF.

4. Contacts S1 and S2 may be permanently closed from start of program after power supply.

2.5. RESETTING

For resetting to default settings (zero) it is necessary in program mode switch SEQ/COMB in

opposite position.

12

2.6. SETTINGS COPYING

If the switch INDIVID/COPY ALL is in position COPY ALL under mode RUN causes copying

settings of the first channel in settings of other channels. In position INDIVID time of each channel

and combination requires individual setting.

2.7. PAUSE

Zero potential between inputs I1 and I2 causes stop of countdown of current time of active

channel till the moment when the closure between these inputs will be removed.

2.8. CYCLE OPERATION OF TIMER

For timer cycle operation (see Diagram 1.2) it is required that inputs C1 and C2 should be open.

Otherwise, the program will be executed only once (see Diagram 1.1).

2.9. JOINT OPERATION OF SEVERAL TIMERS IN SEQUENTIOAL MODE

In case of cascade connection of several timers, outputs O1 and O2 of the first timer should be

connected to inputs S1 and S2 of the second timer, respectively etc., and inputs C1 and С2 should be

short-circuited between each other. For cycle operation of all timers in case of cascade connection it is

necessary to connect outputs O1 and O2 of last timer to connect to the inputs S1 and S2 of the first

one.

Contact:

NOVATEK ELECTRO (INDIA) PVT. LTD.

C-30, Patparganj Industrial Area, 1st floor,

DELHI –110092, INDIA

TEL: 011 42143253

FAX: 011 43010600

EMAIL: novatek.india@novatek-electro.com

NOVATEK ELECTRO INDIA PVT. LTD.

C-30, 1ST FLOOR,

PATPARGANJ INDUSTRIAL AREA

DELHI- 110092

INDIA

PH. NO:- +91-11-42143253, 43010600

EMAIL:- [email protected]

Table of contents

Other Novatek-electro Timer manuals