User Manual XTO 2.ie

Contents

Information................................................................................................................................2

NOTES ON THE CORRECT USE OF THE PRINTER ..............................................................................2

GENERAL NOTES...............................................................................................................................2

SAFETY NOTICES...............................................................................................................................3

GENERAL PRECAUTIONS ..................................................................................................................3

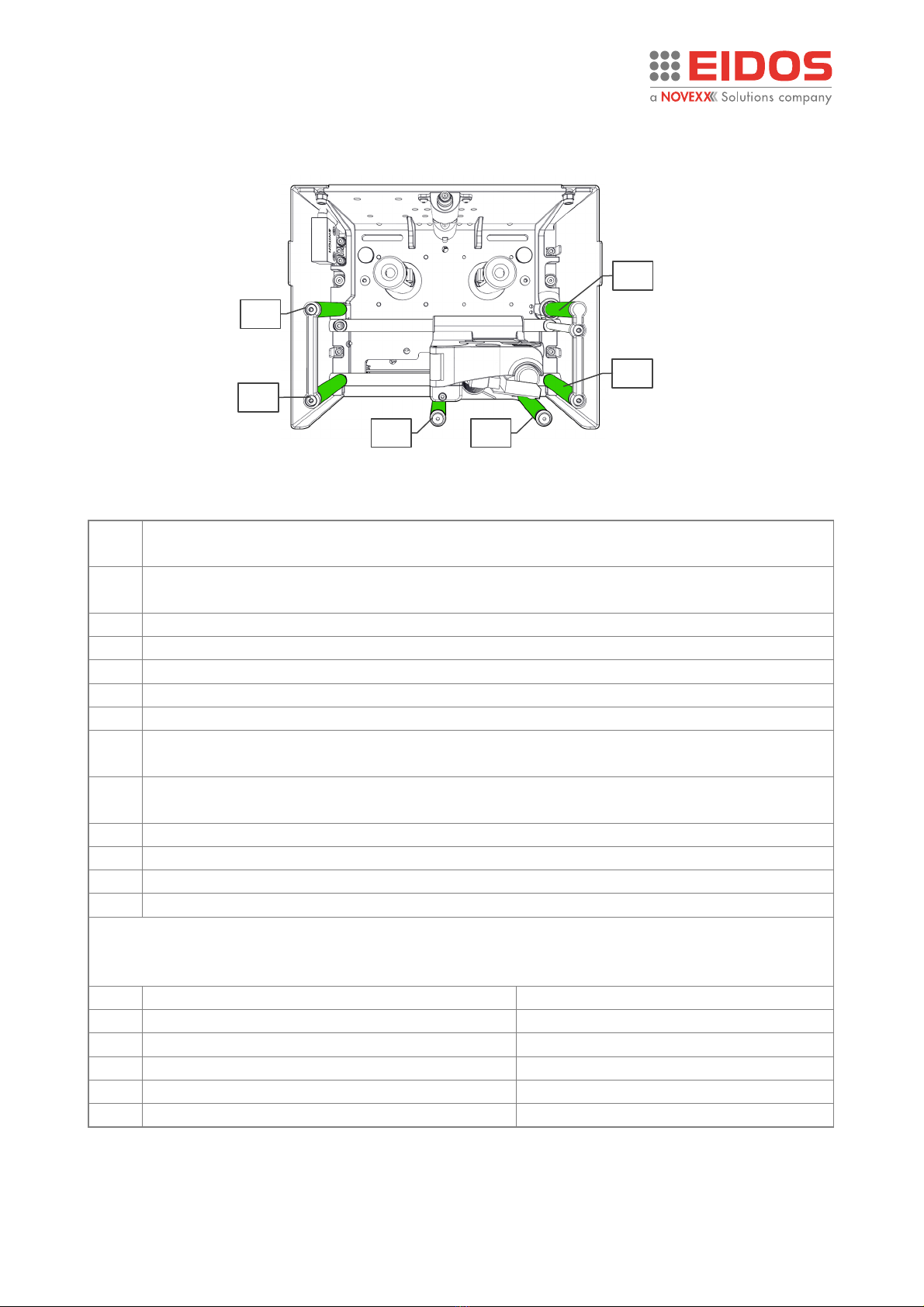

DANGEROUS AREAS ON THE XTO2.IE PRINTING UNIT ....................................................................4

PROTECTION ELEMENTS PROVIDED ON XTO2.IE.............................................................................7

Product Description .................................................................................................................11

FUNCTIONALITY .............................................................................................................................11

PECULIARITY ...................................................................................................................................11

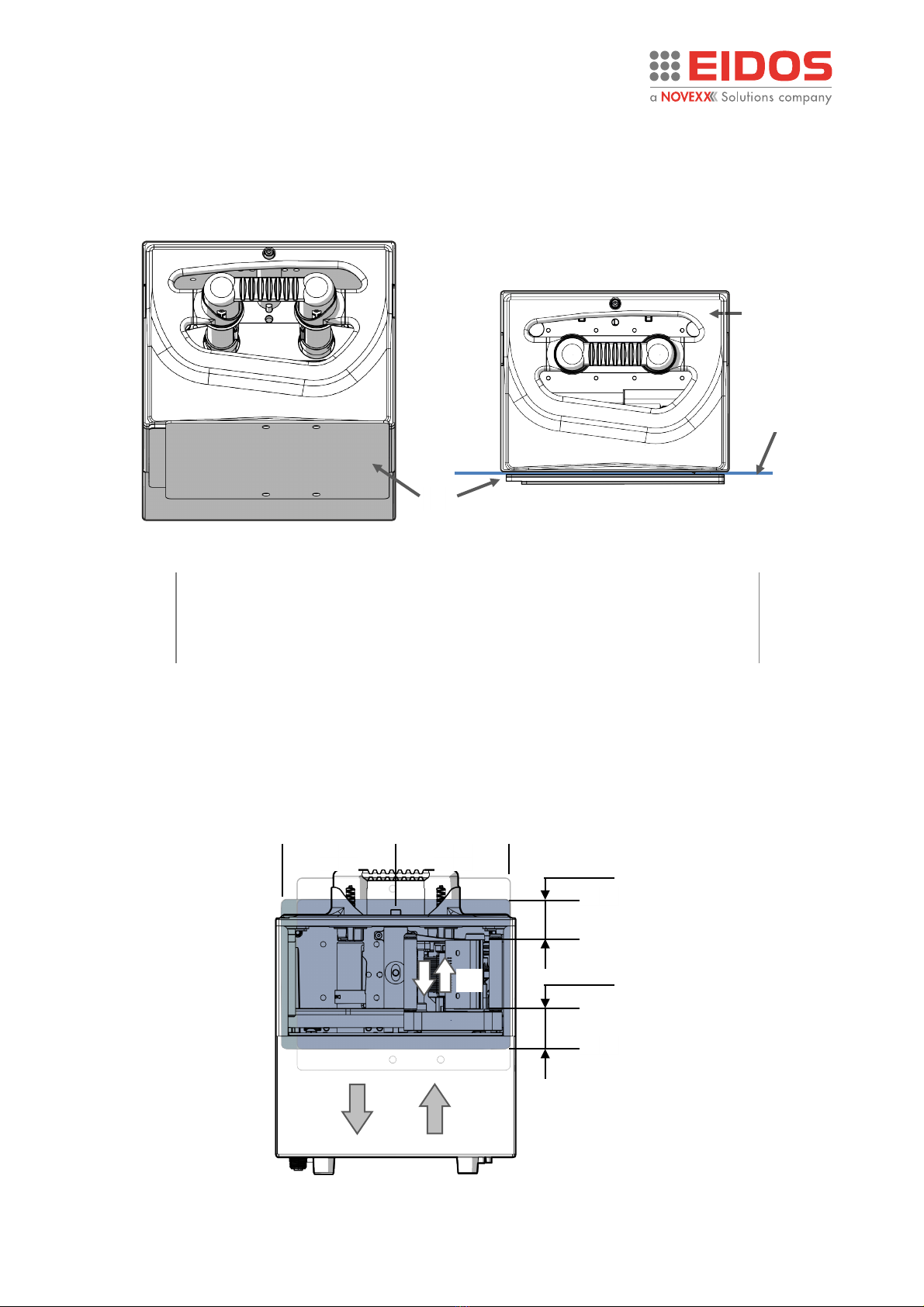

SYSTEM MODELS............................................................................................................................12

REAR CONNECTION PANEL ............................................................................................................13

OPERATING PANEL.........................................................................................................................14

BASIC SETTINGS..............................................................................................................................17

Operation ................................................................................................................................22

INSERTING CONSUMABLES ............................................................................................................22

THE THERMAL RIBBONS .................................................................................................................24

PRINTING........................................................................................................................................25

CREATION AND SENDING OF THE LABEL WITH EASYCODE ...........................................................26

HOW TO STORE LABEL FILES (.LM1)...............................................................................................28

HOW TO BACK UP ..........................................................................................................................28

SETTING AND MONITORING ..........................................................................................................29

STATUS MESSAGES.........................................................................................................................45

Preventive Maintenance ..........................................................................................................47

CLEANING INSTRUCTIONS..............................................................................................................47

CLEANING THE PRINT HEAD...........................................................................................................48

CLEANING THE PRINTING PLATE....................................................................................................48

CLEANING ROLLS AND RIBBON PASSAGES ....................................................................................49

CLEANING THE CARRIAGE SLIDING GUIDE.....................................................................................50

XTO 2.ie with XLS 20x labeller ..................................................................................................51

SYSTEM CONFIGURATION..............................................................................................................51

START UP AND OPERATION ...........................................................................................................52

FUNCTIONALITY DESCRIPTION AND SYNCHRONISMS ...................................................................53

CHANGE OF LABEL ROLL AND LABEL RIBBON................................................................................54

REGULAR MAINTENANCE OF THE LABELLER .................................................................................54

Appendix 1...............................................................................................................................55

EC DECLARATION OF CONFORMITY...............................................................................................55

Appendix 2...............................................................................................................................56

CE LABEL.........................................................................................................................................56