TEMPERATURE CONTROLLER

N323TR

OPERATING MANUAL -V1.8x E

Man 5001288

N323TR is a temperature controller for cooling systems that has a number of specially developed

functions for applications in temperature control and defrosts optimization. It presents an internal

clock for defrost schedule, with weekly schedule, daily or days or working days. It has two input

channels for temperature sensors, NTC thermistors, to measure the temperature of the supervised

environment and the evaporator module. It has three independent outputs for the control of the

compressor (cooling output), defrost module and fan.

The characteristics of the controller are in accordance with the purchase order and are shown on

the label attached to the case of the controller.

SPECIFICATIONS

SENSOR INPUT:.................................................................................................... 2 Thermistors NTC

............................................................................................................................ Type 10 k

@ 25 °C

................................................................................................... Range: –50 to 120 °C (-58 to 248°F)

......................................................................................................................Accuracy: 0.6 °C (1.1 °F)

Note: The sensors come with the equipment. Its operating range is limited to –30 to +105 °C (–222

to +221 °F). It has cable of 3 m in length, 2 x 0.5 mm², and can be extended up to 200 meters.

Maximum error in the interchangeability of original NTC sensors: 0.75 °C (33.35 °F). This error can

be eliminated through the offset parameter of the equipment.

Measurement Resolution:.................................................. 0.1 °C in the range of –19.9 to 119.9 °C

.................................................................................................................. 1 °C in the rest of the range

Note: The equipment keeps its precision all over the range, despite the lack of display resolution

in a part of the range does not allow its visualization.

OUTPUT1: ............................................... Relay SPDT; 1 HP 250 Vac / 1/3 HP 125 Vac (16 A Res.)

..................................................................Optionally: Pulse, 5 Vdc, 25 mA max.

OUTPUT2:...........................................................................................Relay SPST-NA, 3 A / 250 Vac

OUTPUT3:...........................................................................................Relay SPST-NA, 3 A / 250 Vac

POWER SUPPLY: Tension:..................................... 100 to 240 Vca/cc ±10 %

Optionally:...................................................... 12 to 30 Vdc

Frequency:.......................................................... 50~60 Hz

Consumption: ............................................................. 5 VA

Dimensions: Width x Height x Depth:.................................................... 75 x 33 x 75 mm

Weight: ...............................................................................................100 g

Panel cut-out:............................................................................70 x 29 mm

Environment: Operation temperature:...............................0 to 40 °C (32 to 104 °F)

Storage temperature: ............................... -20 to 60 °C (-4 to 140 °F)

Relative Humidity: ....................................................... 20 to 85 % UR

Case in Polycarbonate UL94 V-2; Protection: box IP42, front panel IP65;

Suitable wiring 4.0 mm²; Interface RS485 MODBUS protocol (optional);

Non-isolated serial interface input circuit. Isolated interface from the supply circuit except in the 24

V supply model.

Recommendations for the Installation

The cables of the temperature sensors must be separated from the control and power supply cables, if

possible, in grounded conduits.

The controller power supply should preferably come from an exclusive power network for the

instruments or in a different circuit from that used by the control output stage.

It is recommended to use RC filters (47 R and 100 nF, series) in coils of contactors, solenoids, etc.

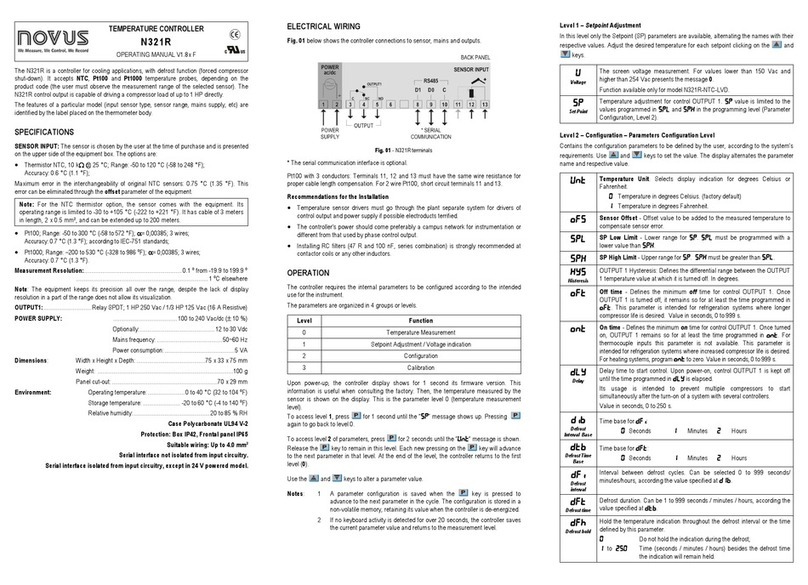

ELECTRICAL WIRING

Figure 01 shows the connection terminals for power supply, sensors and outputs.

Figure 01 – Connections shown in the label on the controller case.

OPERATION

Before using the controller, it must be configured by the user. This setting is to set the values for

the various parameters that determine the operation mode of the equipment. These configuration

parameters are organized into groups or levels, called level parameters.

0 Temperature measurement

1 Setpoint Adjustment

2 Operation Mode

3 Defrost Schedule

4 Calibration

Upon power-up, the N323TR display shows for 1 second its firmware version. This information is

useful when consulting the factory.

The controller then starts to display the value of the environment temperature measured by sensor

1.This is the 0level or Temperature Measurement level. To access the level 1, press for 1

second until the "

" parameter appears. Release the key to stay at this level. Press again

to return to the level of temperature measurement. To access the second level, press for 2

seconds until the "

" parameter appears. Release the key to stay at this level. Press again

to access the other parameters in this level. After the last parameter the controller back to the

level of temperature measurement.

Use the and keys to alter a parameter value:

Notes: 1 The parameters are saved by the controller when it passes from a parameter to

another and only then it will be considered valid. The configuration is stored in a

permanent memory, even in the lack of electrical power.

2 If the keys are not used for more than 20 seconds, the controller returns to the level

of measurement, finalizing and saving the programming previously made.

3 While in the temperature measurement level, a momentary pressing on the key

will show the sensor 2 temperature (evaporator temperature).

Level 1 – Setpoint Adjustment

In this level only the Setpoint (

) parameters are available, alternating the names with their

respective values. Adjust the desired temperature for each setpoint clicking on the and

keys.

Set Point

Case of coldroom temperate adjustment.

value is limited to the values

SPk in the programming level (Parameter

configuration, Level 2).

Level 2 – Level of Operation Mode

Show other parameters that must be set by the user. The parameters are shown alternately with their

respective values.

Temperature Unit. Allows the user to select the temperature unit for all parameters of

Offset value to be added to the sensor 1 measured temperature such as to perform

fine adjustments to the value showed on the display (after sensor replacement, for

instance, if required). In degrees, adjustable from 0.1 to 10.0 degrees.

Offset value to be added to the sensor 2 measured temperature to perform fine

adjustments to the value showed on the display (after sensor replacement, for

instance, if required). Adjustable from -10.0 to 10.0 degrees.

SP Low Limit Setpoint low limit: set a minimum value for the setpoint.

Setpoint high limit: set a maximum value for the setpoint. Must be set to a value

greater than

Hysteresis for output cooling: Difference between ON and OFF for the cooling

output. Adjustable from 0.1 to 50.0 degrees.

Defines the output position for the refrigeration (compressor).

0

Refrigeration in OUTPUT1/ Defrost in OUTPUT2. (factory default)

1Refrigeration in OUTPUT2/ Defrost in OUTPUT1.

Delay

Time delay to start cooling. After the controller is turned on, the cooling output will

only be triggered when the elapsed time set in this parameter. Used in large

refrigeration systems to prevent simultaneous starts for compressors in the return

of power failure. Value in seconds, 0 to 250 s.

On Time

Sets the minimum time to be turned ON the cooling output. Once the cooling output

is activated, it will remain so for at least the time set in this parameter. Typically used

to increase the service life of the compressor in the refrigeration system. Value in

seconds, 0 to 999 s.

Off Time

Sets the minimum time to be turned OFF the cooling output. Once the cooling output

is activated, it will remain so for at least the time set in this parameter. Typically used

to increase the service life of the compressor in the refrigeration system. Value in

seconds, 0 to 999 s. Value in seconds, 0 to 999 s.

Defrost starts as configured in

Defrost starts as schedule.

Defrost

Interval

Interval between defrost. Adjustable from 0 to 999 minutes. During this time, the

defrost output remains off.

0(zero), determines no stops in the defrost process.

Defrost duration. Interval time during which the defrost output remains on.

Value in minutes, 1 to 999.

Defrost

Compressor

Compressor output behavior during the defrost cycle.

Cooling output is OFF during defrost;

Cooling output is ON during defrost;

Compressor output works normally, turning on and off to maintain the

Temperature for finalizing the defrost – Value of the evaporator temperature

measured by the sensor 2 which, when reached determines the end of the defrost

cycle, even if the interval of defrost duration has not ended. Adjustable between –

50 and 120 degrees.

Important note: The defrost cycle will not initiate if the evaporator temperature is

the value defined in this parameter.

Drain down time – After defrost is still necessary a time interval with outputs in

OFF; this is because may there be water accumulated on the evaporator. This

interval must be rated so that these drops of water are eliminated. Adjustable

between 0 and 999 minutes.

Evaporator temperature for liberating the fan – After defrost and the draining,

refrigeration is turned ON immediately because the ambient temperature should

be high. To prevent this hot air circulate in a controlled environment, requiring

more energy to lower the temperature, the controller prevents the ventilation

output (OUTPUT3)is turned ON until the evaporator temperature drops to the

value defined in this parameter.

Fan maximum delay after draining – For the safety of products stored, if the

evaporator temperature does not reach the set value in

, the return of ventilation

will happen at the end of the time interval set in this parameter. Adjustable between 0

and 999 minutes.

Fan behavior during refrigeration.

0

Fan is active only when the compressor is on.

Fan is active during the complete refrigeration cycle, even when the

compressor is turned off.

Fan behavior during defrost.

0

Fan is off during the defrost cycle.

Fan is active during the defrost cycle.

Fan deactivation due to evaporator heating – Turn OFF the fan when the

evaporator heats up, improving system efficiency and protecting the compressor.

The fan is allowed to turn on again when the temperature drops 2 degrees below

the value defined in this parameter.

Compressor

Operation

On Sensor

Error

Sets the behavior of the compressor with sensor 1 (room temperature)

disconnected - When sensor 1 is with issues (disconnected, broken, etc.) the

compressor assumes the condition defined in this parameter.

Compressor is deactivated when sensor 1 is in error.

Compressor is activated when sensor 1 is in error.