Controller N2000S

NOVUS AUTOMATION 2/9

To run smoothly, the controller requires some basic configuration:

•Input type (Thermocouples, Pt100, 4-20 mA, etc.).

•Control setpoint value (SP).

•Control output type (relays, 0-20 mA, pulse).

•PID parameters (or hysteretic for ON / OFF control).

Other special functions, including ramp and soak, alarm timer, digital

input, etc., can be used to achieve better performance.

The setup parameters are grouped in cycles, in which each message

is a parameter to be defined. The 7 parameter cycles are:

The operation cycle (1st cycle) is freely accessed. The other cycles

require a keystroke combination to enable access, as shown below:

Press (BACK) and (PROG) simultaneously

When the required cycle is found, all the parameters within this cycle

can be accessed by pressing the key (or pressing the key to

go backwards). To return to the operation cycle, press many

times up to all parameters of the current cycle have been shown.

All parameters set up are stored in a protected memory. Changed

values are automatically saved when the user goes to the next

parameter. The SP value is saved when parameters are changed or

at every 25 seconds.

CONFIGURATION PROTECTION

It is possible to prevent undue changes, so that the parameter values

cannot be changed after the final configuration. The parameters are

still displayed but can no longer be changed. The protection happens

with the combination of a key sequence and an internal key.

The sequence of keys to protect is and , pressed

simultaneously for 3 seconds in the parameter cycle to protect. To

unprotect a cycle, just press and simultaneously for 3

seconds.

Displays will flash briefly to confirm locking or unlocking

operation.

Within the controller, the PROT key completes the locking function.

When PROT is OFF, the user can lock and unlock the cycles. When

PROT is ON, changes are not allowed. If there are protections for the

cycles, they cannot be removed; if they do not exist, they cannot be

promoted.

CONTROL OPERATION

The controller is based on the SErt parameter (Servo excursion

time). This is the time the serve requires to open completely when it

is in the closed position. The output percentage calculated by the PID

(0 to 100 %) is transformed into the serve activation time to reach a

relative position.

A new output value of the PID is calculated at every 250 ms. The

SErF parameter defines the time in seconds for the calculation and

activation of a new output value. This parameter works as a filter. It

makes the output slower and increases the time intervals.

The minimum resolution for a new position change is given by the

parameter SErr. If the difference between the current output value

and the new value calculated by the PID is lower than the

programmed percentage of this parameter, no activation is

performed.

If the calculated output is between 0 % or 100 % and it is maintained

for some time, the opening relay (when in 0 %) or the closing relay

(when in 100 %) will be periodically activated for a time fraction to

assure that the real position is close to the estimated position, for

mechanical problems or non-linearity of the process.

CONFIGURATION / RESOURCES

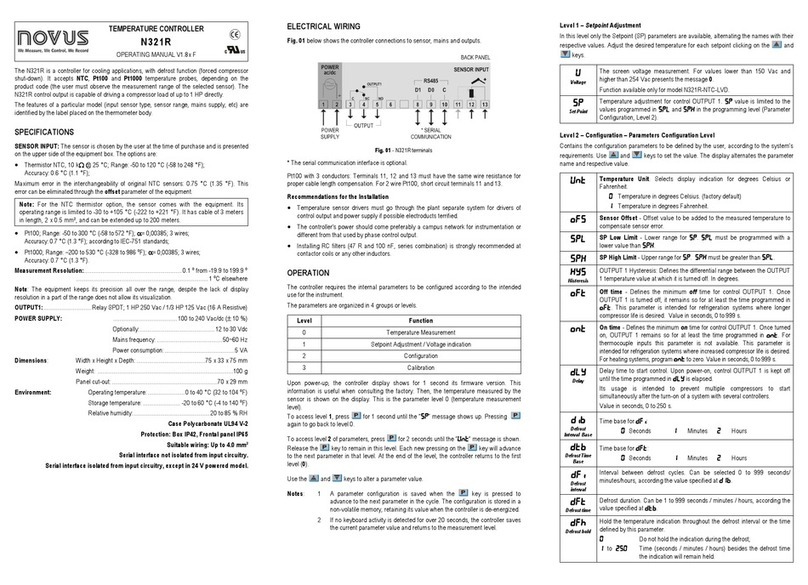

INPUT TYPE SELECTION

The input type must be selected by the user in the Type parameter

and using the keyboard (see input types in Table 1).

J

Range: -50 to 760 °C (-58 to 1400 °F)

K

Range: -90 to 1370 °C (-130 to 2498 °F)

T

Range: -100 to 400 °C (-148 to 752 °F)

N

Range: -90 to 1300 °C (-130 to 2372 °F)

R

Range: 0 to 1760 °C (32 to 3200 °F)

Range: 0 to 1760 °C (32 to 3200 °F)

Pt100

Range: -199.9 to 530.0 °C (-199.9 to 986.0 °F)

Pt100

Range: -200 to 530 °C (-328 to 986 °F)

4-20 mA

J Linearization. Programmable range: -110 to 760 °C

4-20 mA

K Linearization Programmable range: -150 to 1370 °C

4-20 mA

T Linearization. Programmable range: -160 to 400 °C

4-20 mA

N Linearization Programmable range: -90 to 1370 °C

4-20 mA

R Linearization Programmable range: 0 to 1760 °C

4-20 mA

S Linearization Programmable range: 0 to 1760 °C

4-20 mA

Pt100 Linearization. Prog. range: -200.0 to 530.0 °C

4-20 mA

Pt100 Linearization. Prog. range: -200 to 530 °C

0 – 5 0 mV

Linear. Programmable indication from –1999 to 9999.

4-20 mA

Linear. Programmable indication from –1999 to 9999.

0 – 5 Vdc

Linear. Programmable indication from –1999 to 9999.

Input square root extraction.

Table 1 – Input types

Note: All available input types are factory calibrated.

I/O CHANNELS CONFIGURATION

The controller input/output channels can undertake multiple

functions: Control output, digital input, digital output, alarm output,

PV, and SP retransmission. These channels are identified as I/O 1,

I/O2,I/O 3,I/O 4,I/O 5,and I/O 6.

The function code of each I/O can be selected among the following

options. Only valid function codes are displayed for each I/O.

I/O 1 and I/O2 – Used as ALARM outputs

2 SPDT relays are available in terminals 7 to 12. They can be assigned

codes 0, 1 or 2. Where:

0– Disables the alarm.

1– Defines channel as alarm 1.

2 – Defines channel as alarm 2.

I/O 3 and I/O4 – Used as CONTROL outputs

2 SPST relays, available in terminals 3 to 6. They are assigned code

5. Where:

5– Defines channel as control output.

I/O 5 – Analog output

0-20 mA or 4-20 mA analog channel output used to retransmit PV

and SP values or perform functions of digital input and output. They

can be assigned codes 0to 16. Where:

0– No function (disabled).

1– Defines the channel as alarm 1.

2– Defines the channel as alarm 2.

3– Invalid selection.

4– Invalid selection.

5– Invalid selection.

6– Defines the channel to behave as Digital Input and switch

between Automatic and Manual control mode:

Closed = Manual control.