NOVUS PRODUTOS ELETRÔNICOS LTDA. 2/2

4Serial Communications:

MJ1: (RS-232 / RS-485) Use for Cscape programming and Application-Defined

Communications.

MJ2: (RS-232 / RS-485) Use for Application-Defined Communications.

MJ2 Pinouts in Full and Half Duplex Modes

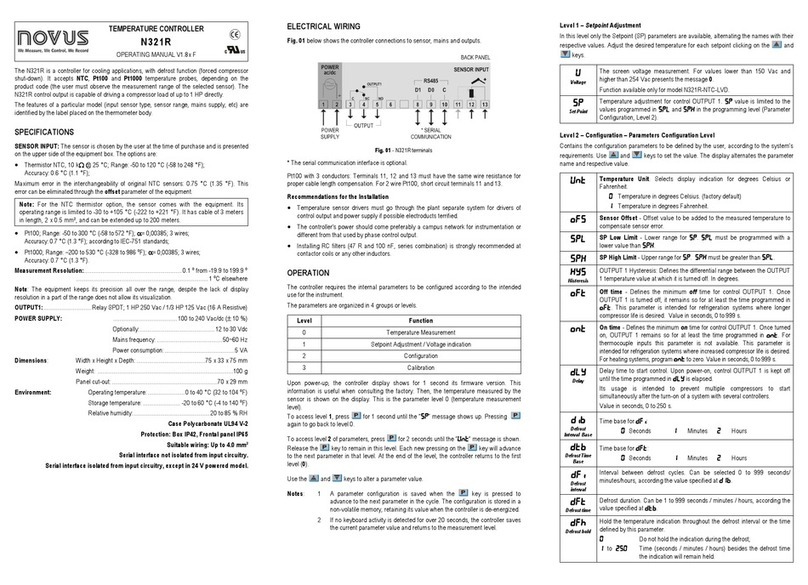

5Wiring and Jumpers

Wire according to the type of inputs / outputs used, and select the appropriate jumper

option.

For I/O wiring / shielded Analog I/O wiring: 0.8 mm2(18 AWG) or larger.

For CAN wiring: 0.2 mm2(24 AWG) or larger.

Use copper conductors in field wiring only, 60/75° C

Orange Connector (J1)

J1 Orange

Terminal

Connector

Black Connector (J2)

J2 Black

Terminal

Connector

I/O Jumpers Settings (JP1 - JP2)

The jumpers JP1 and JP2 are located in the connectors PCB internal to the controller.

JP1 defines the logic of the digital inputs. JP2 defines the input type signal of each

analog channel.

JP1 Digital DC IN1-12 / HSC1-4

Note: When using JP2 (A1-A4), each channel can be independently configured.

(*) Default

External DIP Switch Settings (or Jumpers Settings)

Some XLes have jumpers to set RS-485 port termination, though most use DIP

Switches.

The External Jumpers or DIP Switches are used for termination of the RS-485 ports.

The XLe is shipped un-terminated.

To terminate, select one of the jumpers shipped with the product and insert it based

upon the option that is desired or, select the switch and configure based upon the

option that is desired.

As seen when looking at the top of the XLE unit: Refer to Section 3 for the location of

the DIP Switches (or External Jumpers).

6Safety

This equipment is suitable for use in Class I, Division 2, Groups A, B, C and D or Non-hazardous locations only

WARNING –EXPLOSION HAZARD –Substitution of components may impair suitability for Class I, Division 2

WARNING –EXPLOSION HAZARD –Do not disconnect equipment unless power has been switched off or the

area is known to be non-hazardous.

WARNING: To avoid the risk of electric shock or burns, always connect the safety (or earth) ground before

making any other connections.

WARNING: To reduce the risk of fire, electrical shock, or physical injury it is strongly recommended to fuse the

voltage measurement inputs. Be sure to locate fuses as close to the source as possible.

WARNING: Replace fuse with the same type and rating to provide protection against risk of fire and shock

hazards.

WARNING: In the event of repeated failure, do not replace the fuse again as a repeated failure indicates a

defective condition that will not clear by replacing the fuse.

WARNING: Only qualified electrical personnel familiar with the construction and operation of this equipment and

the hazards involved should install, adjust, operate, or service this equipment. Read and understand this manual

and other applicable manuals in their entirety before proceeding. Failure to observe this precaution could result

in severe bodily injury or loss of life.

7Technical Support

For assistance and manual updates, contact Technical Support at the following

locations:

You can find the complete documentation at www.novus.com.br.

001XLE015

0V ON J1

12-24VDC

R2

C2

R3

C3

R6

C6

R4

C4

R5

C5

R1

C1

H4

H2

H3

LOAD

230VAC

OR

25VDC

N

L

LOAD

230VAC

OR

25VDC

N

L

LOAD

230VAC

OR

25VDC

N

L

LOAD

230VAC

OR

25VDC

N

L

LOAD

230VAC

OR

25VDC

N

L

LOAD

230VAC

OR

25VDC

N

L

I1

I2

I3

I4

0V

A1

A2

0V

I5

I6

I7

I8

A3

A4

H1

001XLE017

12-24VDC

LOOP PWR

20mA

0-10VDC