Power Controller

NOVUS AUTOMATION 2/4

Figure 3

Figure 4

Figure 5

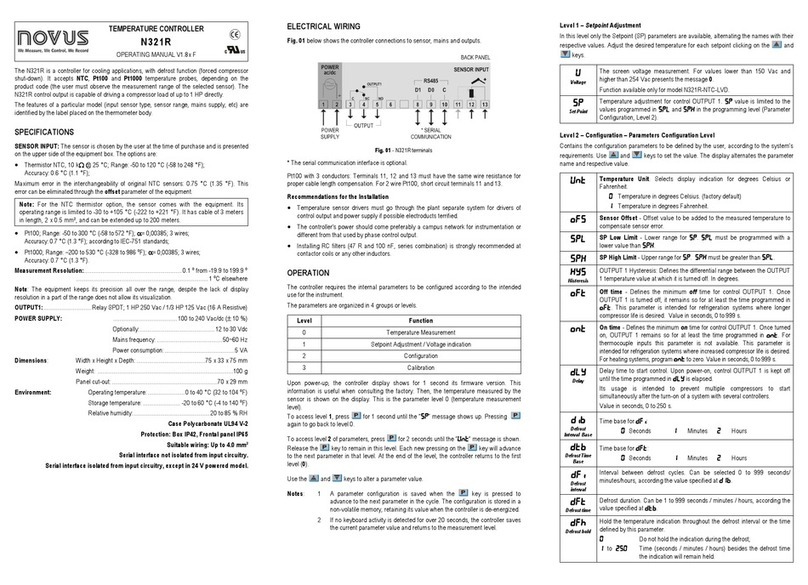

ELECTRICAL CONNECTIONS

The available features of the connector bar for the power controller is

shown in Figure 6 and 7:

Figure 6 – Connector bar for the power controller, model PCW

Figure 7– Connector bar for the power controller, model PCWE

RECOMMENDATIONS FOR THE INSTALLATION

•To minimize the pick-up of electrical noise, the low voltage DC

connections and the sensor input wiring should be routed away

from high-current power conductors. If this is impractical, use

shielded cables. In general, keep cable lengths to a minimum.

•All electronic instruments must be powered by a clean mains

supply, proper for instrumentation.

•It is strongly recommended to apply RC'S FILTERS (noise

suppressor) to contactor coils, solenoids, etc.

•In any application it is essential to consider what can happen

when any part of the system fails. The controller features by

themselves can not assure total protection.

RESOURCES

CONTROL SIGNAL (INPUT)

The control signal is selected by the user during the configuration of

the power controller. There are (7) different types of control signals

accepted:

•4~20 mA

•0~20 mA

•1~5 V

•2~10 V

•0~5 V

•0~10 V

•10 k Power meter

The control signal should be applied in terminals 1, 2 and 3 of the

controller’s connector bar.

MANUAL CONTROL

Feature that allows the user to manually establish the percentage

value of the power delivered to the load. The options for a manual

control are:

- Via keypad adjustment. Available when following a

recommendation such as "Manual percentage value of the power

delivered to the load." See Mode of Operation later in this manual.

- Via power meter in Input.

- Via power meter in Limit. MANUAL digital entry, available in

terminals 6 and 7, selects the adoption of the manual control mode

when activated (closed switch). In the open switch position, the

Limit connected power meter begins to execute the Load Limit

function.

LOAD LIMIT (LIMIT)

Feature that determines the maximum power limit to be delivered to

the load, regardless of the value demonstrated by the control signal.

A potentiometer, of 10 k Ohms, installed in the Limit establishes this

maximum value. For this function to work, the MANUAL digital entry

should remain in the closed position (AUTO).

This limit is not in regards to the load current. It limits the portion

of the network cycle, or the network cycle number, applied to the

load. For the processes where the load does not have linear

behavior, the load current should be known and considered.

TYPE OF CONTROL

There are two types of possible controls in this power controller:

PWM control and Phase Angle control.