Controller N3000

NOVUS AUTOMATION

8/9

ANALOG OUTPUT CALIBRATION

1. Select type 11 or 12 at the I/O5 prompt.

2. Connect a current meter at the analog output.

3. Disable the auto-tune and soft-start functions.

4. Set the output low limit ovLL

ovLLovLL

ovLL to 0.0 % and the output high limit

ovkL

ovkLovkL

ovkL to 100.0 %.

5. Select the manual mode at the avto

avtoavto

avto prompt.

6. Enable the output at the rvn

rvnrvn

rvn prompt.

7. t the operation cycle, set the MV to 0.0 %.

8. t the output low calibration ovLC

ovLCovLC

ovLC prompt, press the and

key until the m meter reads zero m . pproach this value

from above.

9. Set 100.0 % for the manipulated variable (MV).

10. t the output high calibration ovkC

ovkCovkC

ovkC prompt, press the and

key until the m meter reads 20 m . pproach this value

from below.

11. Repeat steps 7. to 10. as necessary.

PROBLEMS WITH THE CONTROLLER

Connection errors or improper configuration will result in malfunctioning

of the controller. Carefully revise all cable connections and programming

parameters before operating the unit.

Some error messages will help the user identify possible problems.

MESSAGE POSSIBLE PROBLEM

-----

----------

-----

Open input. No sensor is connected or the sensor is

broken.

Err1

Err1Err1

Err1

Err6

Err6Err6

Err6

Pt100 cable resistance is too high or the sensor is badly

connected.

Different messages other than the ones above should be reported to

the manufacturer. Please inform the serial number if this should

occur. The serial number can be viewed at the display by pressing

the key for about 3 seconds.

The software version of the instrument can be viewed at the time the

unit is powered.

When not properly configured, the instrument may show false error

messages, particularly those related to the type of input selected.

The controller also has a visual alarm (the display flashes) when the

PV value is out of the range set by spxl

spxlspxl

spxl and spll

spllspll

spll.

SERIAL COMMUNICATION

The indicator can be supplied with an asynchronous RS-485 digital

communication interface for master-slave connection to a host

computer (master).

The indicator works as a slave only and all commands are started by

the computer which sends a request to the slave address. The

addressed unit sends back the requested reply.

Broadcast commands (addressed to all indicator units in a multidrop

network) are accepted but no reply is sent back in this case.

CHARACTERISTICS

•RS-485 compatibility with two-wire connection from the host to up

to 31 slaves in a multidrop network topology. Up to 247 units can

be addressed by the MODBUS RTU protocol. Maximum network

distance: 4,000 feet. Time of indicator disconnection: Maximum of

2 ms after the last byte.

•Te communication signals are electrically isolated from the rest of

the instrument, and can be 1200, 2400, 4800, 9600, 19200, 38400,

and 57600 bps.

•Number of data bits: 8, without parity or pair parity

•Number of stop bits: 1

•Time to start response transmission: up to 100 ms after

acknowledging the command.

•Protocol: MODBUS (RTU)

RS485 INTERFACE: ELECTRICAL CONNECTION

The RS-485 signals are:

D1

D D +

B Bidirectional data line Terminal 25

D0

D:

D -

A Inverted bidirectional data line Terminal 26

C

GND

Optional connection to improve

communication performance

Terminal 27

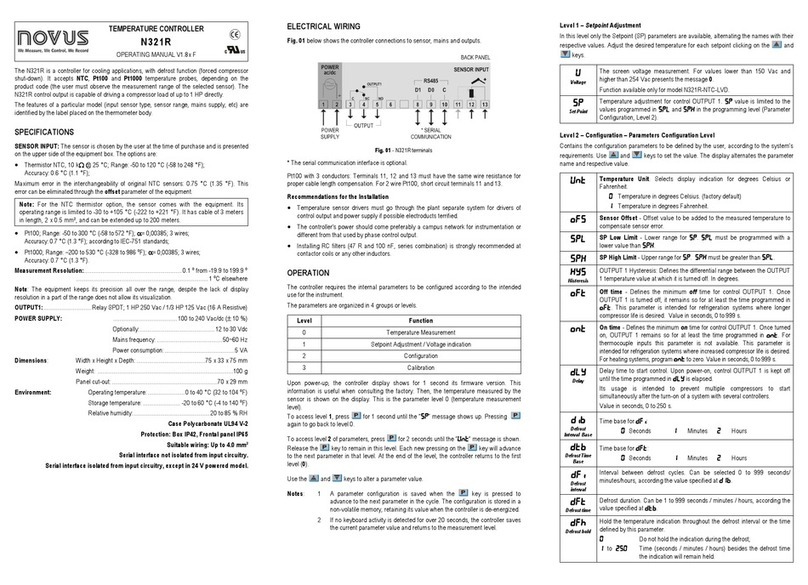

SPECIFICATIONS

DIMENSIONS: ................. 96 x 96 x 92 mm. Peso proximado: 350 g

TERMINAL CONECCTION: ..... 24 screws acceping 6.3 mm fork lugs

PANEL CUT-OUT: ...................................93 x 93 mm (+0.5 -0.0 mm)

POWER:..................................... 100 a 240 Vac/dc (±10 %), 50/60 Hz

Optional: ............................................................ 24 Vac/dc ±10 %

Max. Consumption:................................................................ 9 V

ENVIRONMENTAL CONDITIONS:....................................... 5 a 50 ºC

Relative humidity (maximum): .............................80 % up to 30 ºC

.................... For temperatures above 30 ºC, decrease 3 % per ºC

....... Installation category II. Pollution degree 2. ltitude < 2000 m

INPUT.................... Keyboard selection of input type (refer to Table 1)

Internal resolution: .................................................. 19500 levels

Display resolution: .................12000 levels (from -1999 to 9999)

Input sample rate:....................................................5 per second

Accuracy: ..........Thermocouples J, K e T: 0.25 % of span ±1 ºC

.............................Thermocouples N, R, S: 0.25 % do span ±3 ºC

...................................................................... Pt100: 0.2 % of span

....................................4-20 m , 0-50 mV, 0-5 Vdc: 0.2 % of span

Input impedance:. 0-50 mV, Pt100 and thermocouples: >10 MΩ

................................................................................. 0-5 V: >1 MΩ

.................................................4-20 m : 15 Ω (+2 Vdc @ 20 m )

Pt100 measurement:................................... standard (=0.00385)

Excitation current:.................................0,170 m . 3-wire circuit,

cable resistance compensation.

ll input types are factory calibrated according to IEC-584 for

thermocouples and IEC-751 for Pt100.

DIGITAL INPUT (I/O6): .................. Dry contact or NPN open collector

ANALOG OUTPUT (I/O5):..............0-20 m or 4-20 m , 550 Ω max.

1500 levels, Isolated, para controle ou retransmissão de PV e SP

.....................................Control output or PV or SP retransmission

CONTROL OUTPUT: 2 Relays SPDT (I/O1 and I/O2): 3 / 240 Vac

2 Relays SPST-N (I/O3 and I/O4): 1,5 / 250 Vac

Logic pulse for SSR drive (I/O5): 10 V max / 20 m

SECOND ANALOG INPUT: 4-20 m remote set point (standard).

EMC:................................EN 61326-1:1997 and EN 61326-1/ 1:1998

SAFET : ...........................EN61010-1:1993 and EN61010-1/ 2:1995

Back panel: IP65, Polycarbonate UL94 V-2; Box: IP30, ABS+PC

UL94 V-0

Programmable PWM cycle from 0.5 seconds and 100 seconds;

Start up 3 seconds after power up.

ORDERING INFORMATION:

N3000 - 485 - 24V

A B C

A: Series model: N3000;

B: Digital communication: blank

485 (RS485, Modbus protocol)

C: Voltage rating: blank (100 to 240 Vac);

24V (24 Vac/dc);