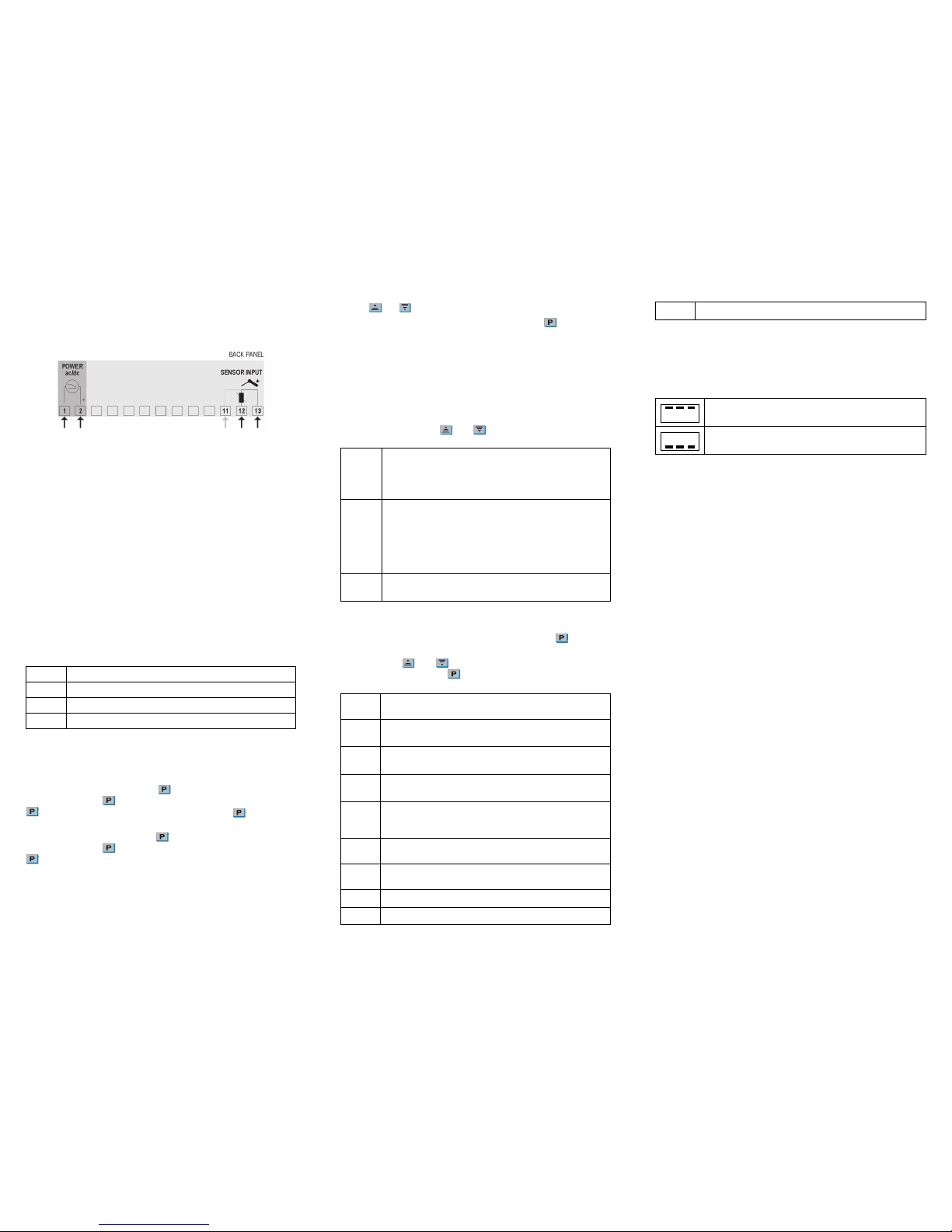

ELECTRICAL WIRING

Fig. 1 below shows the temperature meter connections to sensor, mains and

outputs.

Fig. 1 – N320 terminals

Pt100 with 3 conductors. Terminals 11, 12 and 13 must have the same wire

resistance for proper cable length compensation. For 2 wire Pt100, short circuit

terminals 11 and 13.

It is important to follow the recommendations below

•Signal wires should be installed in grounded conduits and away from power or

contactor wires.

•The instrument should have its own power supply wires that should not be

shared with electrical motors, coils, contactors, etc.

•Installing RC filters (47 R and 100 nF, series combination) is strongly

recommended at contactor coils or any other inductors.

•System failure should always be taken into account when designing a control

panel to avoid irreversible damage to equipment or people.

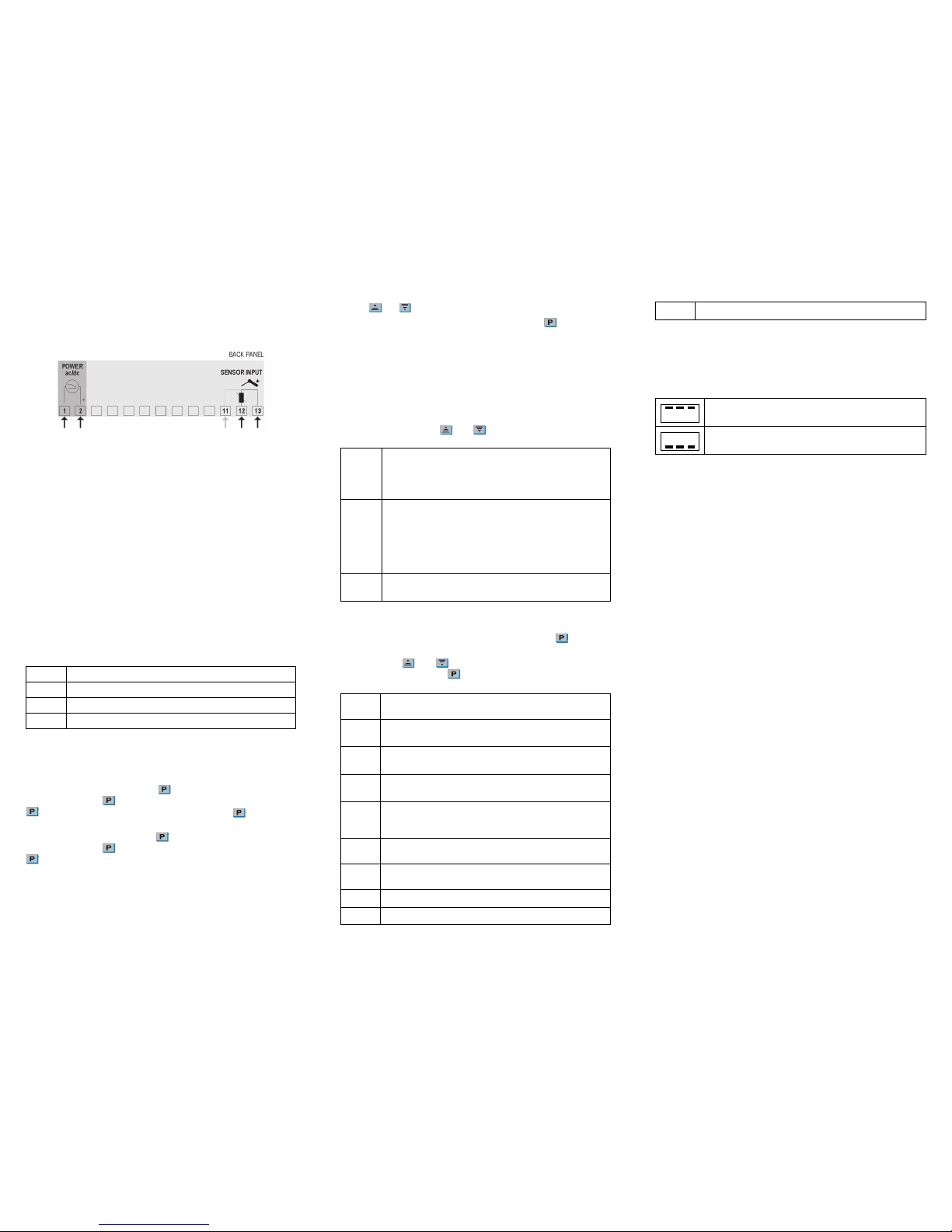

OPERATION

The temperature meter requires the internal parameters to be configured according

to the intended use for the instrument. The parameters are organized in 3 groups or

levels:

Level Function

2 Calibration

Upon power-up, the N320 display shows for 1 second its firmware version. This

information is useful when consulting the factory.

Then, the temperature measured by the sensor is shown on the display. This is

the parameter level 0(Temperature Measurement level).

To access level 1 of parameters, press for 1 second until the

message

is shown. Release the key to remain in this level. Each new pressing on the

key will advance to the next parameter in the level. Press again to return

to the initial screen (temperature display).

To access level 2 of parameters, press for 2 seconds until the

message

is shown. Release the key to remain in this level. Each new pressing on the

key will advance to the next parameter in the level. At the end of the level, the

temperature meter returns to the first level (0).

Use the and keys to alter a parameter value.

Notes: 1 A parameter configuration is saved when the key is pressed

to advance to the next parameter in the cycle. The configuration

is stored in a non-volatile memory, retaining its value when the

thermometer is de-energized.

2 If no keyboard activity is detected for over 20 seconds, the

thermometer saves the current parameter value and returns to

the measurement level.

Level 1 – Configuration Level

Contains the configuration parameters to be defined by the user, according to the

system’s requirements. Use and keys to set the value. The display

alternates the parameter name and respective value.

Selects display indication for degrees Celsius

Temperature in degrees Celsius

Temperature in degrees Fahrenheit

Input Type - Selects the input sensor type to be connected to the

temperature meter. Available only for thermocouple models,

allowing selection of types J, K and T.

Offset value to be added to the measured

temperature to compensate sensor error.

Level 2 – Calibration level

The temperature meter is factory calibrated. The following parameters should be

accessed only by experienced personnel. To enter this cycle, the key must be

kept pressed for 3 seconds.

Don’t press the and keys if you are not sure of the calibration

procedures. Just press the key a few times until the temperature

measurement level is reached again.

Password - Enter the correct password to

for the parameters in the following levels.

Offset value of the input. It adjusts the lower

measurement range of the sensor.

Calibration High - Gain calibration

measurement range of the sensor.

Cold Junction Offset calibration -

This parameter is available

Restores factory calibration

parameters. Change from 0to 1to restore the calibration

parameters with factory values.

the levels of parameters that will be password

protected. See "Configuration Protection" for details.

Password Change - Allows changing the current password to a

new one. Values from 1 to 999 are allowed.

Serial number - First part of the temperature meter serial number.

Serial number - Second part of the temperature meter serial number.

Serial number - Third part of the temperature meter serial number.

ERROR MESSAGES

Sensor measurement errors force the temperature meter outputs to be turned off.

The cause for these errors may have origin in a bad connection, sensor defect

(cable or element) or system temperature outside the sensor working range. The

display signs related to measurement errors are shown below:

Measured temperature exceeded maximum allowed range for

the sensor. Broken Pt1000 or T/C. Short circuited NTC sensor.

Measured temperature is below m

inimum measurement range of

the sensor. Short circuited Pt1000 or T/C. Broken NTC.

CONFIGURATION PROTECTION

A protection system to avoid unwanted changes to the temperature meter

parameters is implemented. The level of protection can be selected from partial to

full. The following parameters are part of the protection system:

When this parameter is presented, the correct password should be entered

to allow changes of parameters in the following levels.

Defines the level of parameters that will be password protected:

1 -Only calibration level is protected (factory configuration);

2 -Calibration and configuration levels are protected;

3 -All levels are protected - calibration, configuration and SP.

Parameter for definition of a new password. Since it is located in the

calibration level, can only be changed by a user that knows the current

password. Valid passwords are in the range 1 to 999.

CONFIGURATION PROTECTION USAGE

parameter is displayed before entering a protected level. If the correct

password is entered, parameters in all following levels can be changed. If wrong

or no password is entered, parameters in the following levels will be read only.

Important notes:

1- After five consecutive attempts to enter a wrong password, new tentative will

be blocked for the next 10 minutes. If the current valid password is unknown,

the master password can be used only to define a new password for the

temperature meter.

2 - The password for a brand new device is 111.