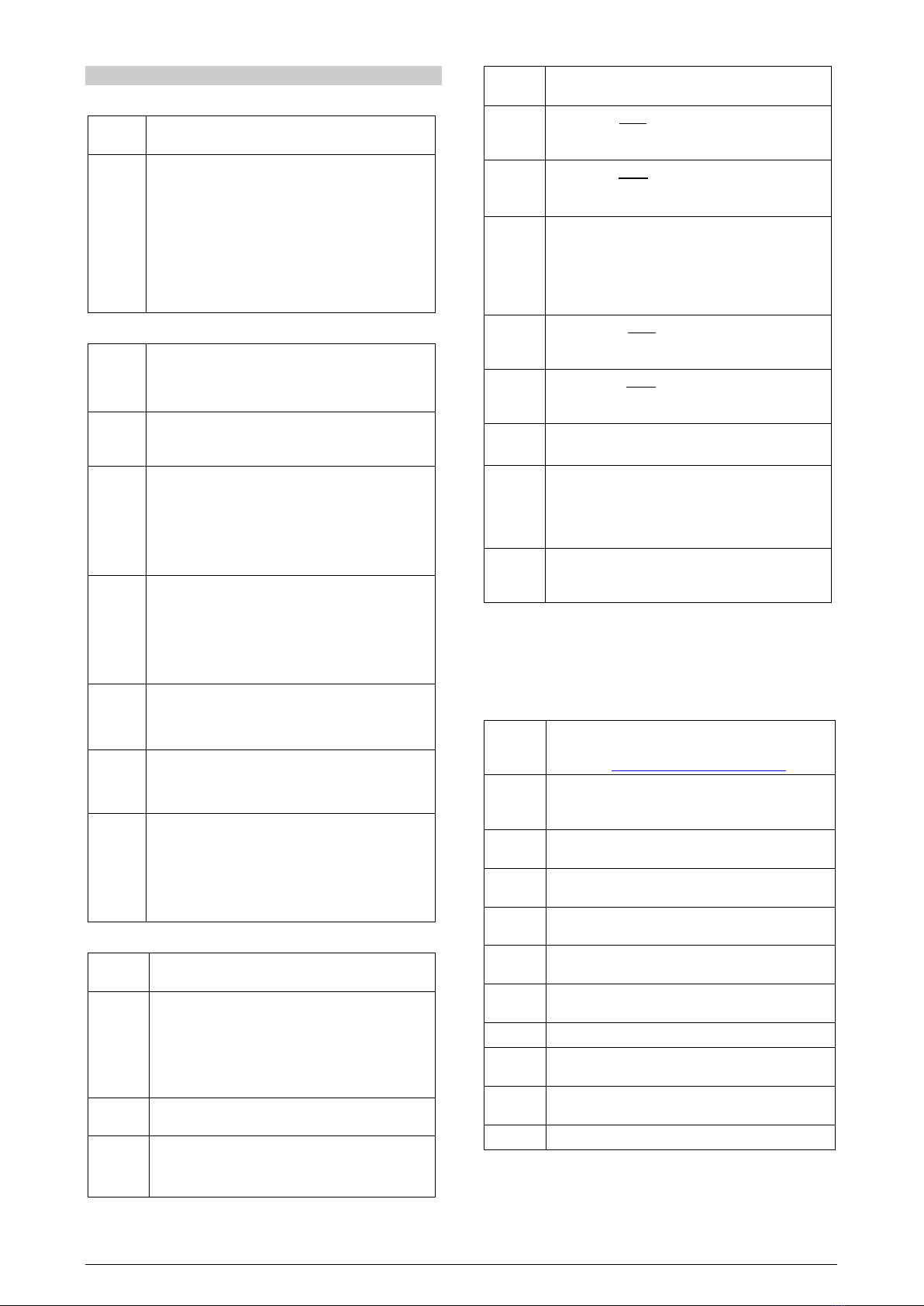

N1040i Digital Panel Meter

NOVUS AUTOMATION 2/7

Alarm of the maximum differential value. It triggers when

the PV value is above the point defined by:

+

(using alarm 1 as an example).

SPA1 positive SPA1 negative

Alarms of the Sensor Break. It is activated when the

Input presents problems such as interrupted sensor, bad

connection, etc.

Table 2 –Alarm functions

Note: The figures are also valid for Alarm 2 (SPA2).

Important note: Alarms configured with the ki, dif and dif.k

functions also trigger their associated output when a sensor fault is

identified and signaled by the digital panel meter. A relay output, for

example, configured to function as a High Alarm (ki), will operate

when the SPAL value is exceeded and when the sensor connected

to the digital panel meter input is broken.

ALARM INITIAL BLOCKING

The initial blocking option inhibits the alarm from being recognized

if an alarm condition is present in the process when the digital panel

meter is turned on. The alarm will be enabled only after the

occurrence of no alarm condition.

The initial blocking is useful, for example, when one of the alarms is

configured as a minimum value alarm, which can cause the alarm to

be triggered as soon as the process is started (often undesired

behavior).

The initial blocking is not valid for theierr (Sensor Break) function.

OFFSET

Feature that enables you to make small adjustments to the PV

indication. Allows to correct measurement errors that appear, for

example, when replacing the temperature sensor.

USB INTERFACE

The USB interface is used to CONFIGURE, MONITOR or UPDATE

the controller FIRMWARE. You should use QuickTune software,

which offers features to create, view, save and open settings from

the device or files on the computer. The tool for saving and opening

configurations in files allows you to transfer settings between devices

and perform backup copies.

For specific models, QuickTune allows to update the controller

firmware (internal software) via the USB interface.

For MONITORING purposes, you can use any supervisory software

(SCADA) or laboratory software that supports the MODBUS RTU

communication over a serial communication port. When connected to

a computer USB, the controller is recognized as a conventional serial

port (COM x).

You must use QuickTune software or consult the DEVICE

MANAGER on the Windows Control Panel to identify the COM port

assigned to the controller.

You should consult the mapping of the MODBUS memory in the

controller communication manual and the documentation of the

supervision software to start the MONITORING process.

Follow the procedure below to use the USB communication of the

device:

1. Download QuickTune software from our website and install it on

the computer. The USB drivers necessary for operating the

communication will be installed with the software.

2. Connect the USB cable between the device and the computer.

The controller does not have to be connected to a power supply.

The USB will provide enough power to operate the

communication (other device functions may not operate).

3. Run QuickTune software, configure the communication and

start the device recognition.

The USB interface IS NOT ISOLATED

signal input (PV) or the digital inputs and outputs. It is

intended for temporary use during CONFIGURATION

and MONITORING periods.

For the safety of people and devices, it must only be

used when the device is completely disconnected

from the input/output signals.

Using the USB in any other type of connection is

possible but requires a careful analysis by the person

responsible for installing it.

When MONITORING for prolonged periods and with

connected inputs and outputs, it is recommended to

use

the RS485 interface, which is available or

optional in most of NOVUS products.

PV RETRANSMISSION

The digital panel meter may include an analog output which performs

the retransmission of the values of PV into a signal of 0-20 mA or 4-

20 mA. The analog retransmission can be scaled, i.e., there are

minimum and maximum limits to establish the retransmission range,

defined in the rtLL and rtkL parameters.

The analog output is available on terminals 13 and 14 for models

N1040i-RA and N1040i-RA-485.

To obtain retransmission in electrical voltage, you must install a

shunt resistor (500 Ω max.) across the analog output terminals. This

resistor value depends on the desired voltage range.

The analog retransmission output is not electrically isolated from the

RS485 serial communication.

24 Vdc AUXILIARY VOLTAGE SOURCE

Another feature that may be available in the digital panel meter is an

auxiliary power supply for exciting field transmitters (two-wire 4-20

mA transmitters).

The 24 Vdc output is on terminals 13 and 14 for models N1040i-RE

and N1040i-RE-485.

The 24 V auxiliary power supply is not electrically isolated from the

RS485 serial communication.

INSTALLATION / CONNECTIONS

The digital panel meter shall be fastened on a panel, following the

sequence of steps described below:

•Make a 46 x 46 mm cutout in the panel.

•Remove the mounting clip from the digital panel meter.

•Insert the digital panel meter.in the cutout from the front of the

panel.

•Replace the clip on the digital panel meter, pressing until you get

a tight hold.

ELECTRICAL CONNECTIONS

Figure 1 shows the layout of the features on the rear panel of the

digital panel meter:

Figure 1 –Inputs connections and power supply