NRD, LLC / 2937 Alt Boulevard / Grand Island, NY 14072

PHONE 716 773 7634 / FAX 716 773 7744 / EMAIL sales@nrdllc.com / WEB www.nrdllc.com

NRD Asia Pte. Ltd

PHONE +65 6679 1707 / EMAIL sales@NRDasia.com / WEB www.nrdllc.com

INST2001 – 12/22

Please keep this document in a convenient place to refer to as a guide

Maintenance

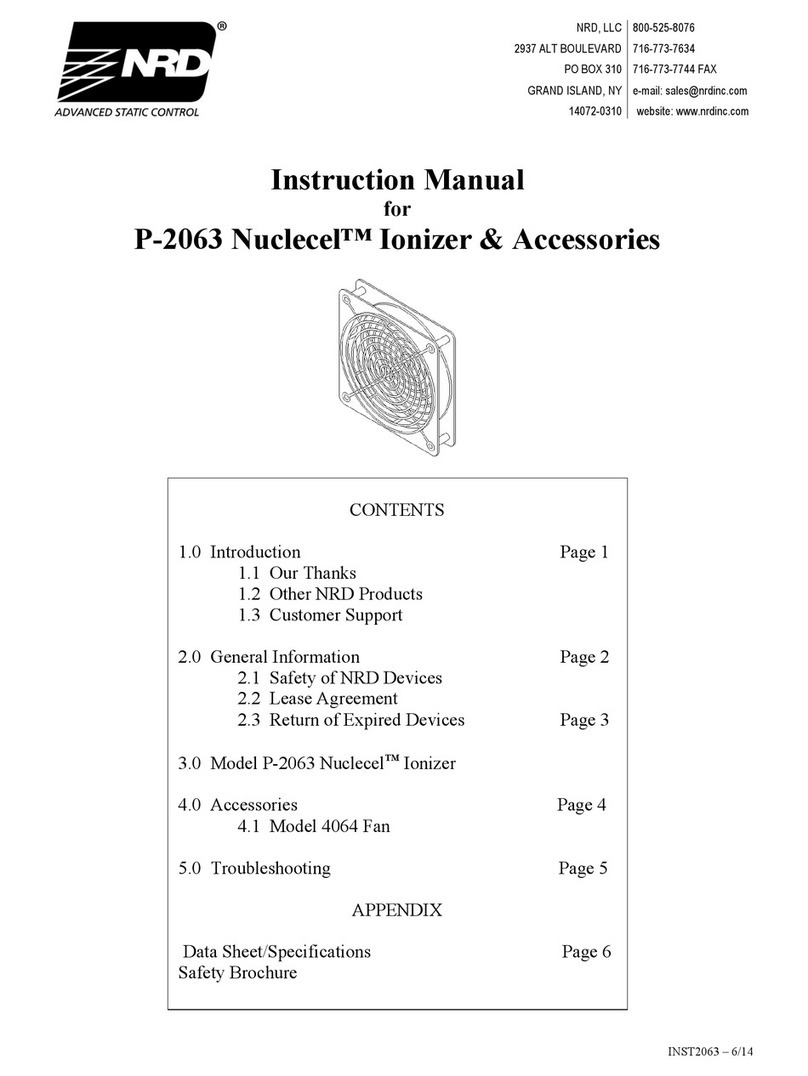

•Maintenance is not required except that the

Nuclestat®

must be kept clean by blowing

dry, filtered, compressed air over its

surface.

Calibration is not required.

•To ensure maximum static removal

efficiency, the Nuclestat®

an

nually regardless of use. The

replacement date is one year after the date

manufactured (printed on each Nuclestat®

).

NRD will remind customers of the

replacement date.

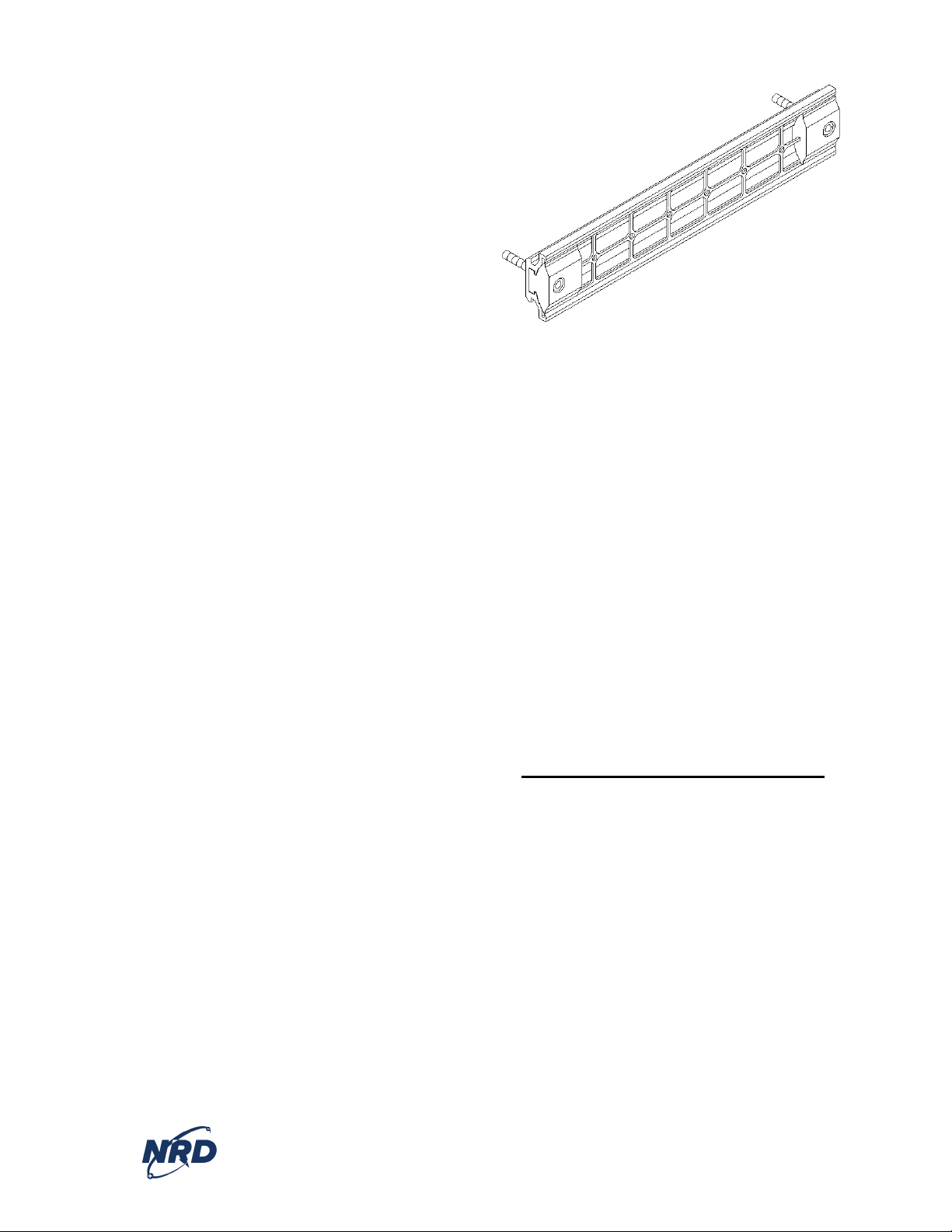

This family of ionizers neutralizes the high

static charges developed in materials being

processed by providing ionized air to them.

Remove the protective cover shield by

sliding it off either end.

Determine a mounting location that will

satisfy the following requirements:

A)

The ionizer will face the side of the

material that is statically charged.

B) The ionizer

will be positioned after the

point where static is developed, e.g.,

after the last static generating roller or

friction point.

C)

The distance between the ionizer (i.e.,

Nuclestat®

grid or Induction Bar

brushes or points) and the charged

material will be 2pprox.. 1-1/8”(3 cm).

D)

No part of the ionizer will contact the

charged material during normal process

operations.

E) If the Model P-2001-

I is to be installed,

the processed material must pass by the

Induction Brushes without contact.

F)

If installing more than one ionizer for a

single application, the ionizers will not

be positioned directly opposite each

other on both sides of the material being

processed.

Mount the ionizer to a rigid structure in the

selected location. Attachment hardware

(two #8-

32 socket head cap screws) is

provided.

Ground the ionizer by attaching the eyelet at

the free end of the grounding strap to ground

potential. (Attachment hardware is not

provided). Ensure that the process

machinery is also grounded. Verify that the

ionizer and machinery are grounded by

having them checked by a qualified

electrician.

The ionizer is now ready for use.