NSK Megatorque PS Series User manual

MEGATORQUE®MOTOR SYSTEM

User’s Manual

(EDC Driver Unit System)

M-E099DC0C2-158

Document Number: C20158-04

Limited Warranty

NSK Ltd. warrants its products to be free from defects in material and/or workmanship which NSK

Ltd. is notified of in writing within, which comes first, one (1) year of shipment or 2400 total

operation hours. NSK Ltd., at its option, and with transportation charges prepaid by the claimant,

will repair or replace any product which has been proved to the satisfaction of NSK Ltd. to have a

defect in material and/or workmanship.

This warranty is the sole and exclusive remedy available, and under no circumstances shall NSK

Ltd. be liable for any consequential damages, loss of profits and/or personal injury as a result of

claim arising under this limited warranty. NSK Ltd. makes no other warranty express or implied,

and disclaims any warranties for fitness for a particular purpose or merchantability.

Copyright 2011 by NSK Ltd., Tokyo, Japan

All rights reserved.

No part of this publication may be reproduced in any

form or by any means without permission in writing

from NSK Ltd.

NSK Ltd. reserves the right to make changes to any

products herein to improve reliability, function or design

without prior notice and without any obligation.

NSK Ltd. does not assume any liability arising out of the

application or use of any product described herein;

neither does it convey any license under its present

patent nor the rights of others.

Patents issued and patents pending.

“MEGATORQUE” is a registered trademark of NSK Ltd. in

Japan and that of NSK Corp. in the United States of

America.

Notes for Proper Use of Megatorque Motor System

1. Precautionary statement for the prolonged use of the Driver Unit

1) Temperature

Keep the ambient temperature of the Driver Unit within 0 to 50[°C]. You cannot use the Driver Unit in a

high temperature atmosphere over 50[°C]. Keep a clearance of 100 mm in the upper and the lower side of

the Driver Unit when it is installed in an enclosure. If heat is built up on the upper side of the Driver Unit,

provide ventilation openings on the top surface or equip a forced air cool unit to take the heat out of the

Driver Unit. (Measures against contamination are required for the ventilation openings.)

2) Dust-proof and Waterproof

Put the Driver Unit in an enclosure with the protection code of IP54 or better. Protect the Driver Unit from

oil-mist, cutting oil, metal chips and paint fume, etc. Otherwise it may result in failure of electric circuits

of the Driver Unit.

(The IP code is to specify the protection level of enclosures from solid contamination and water. It is

specified in the IEC standard and other safety regulations.)

3) Wiring/Ground

Refer to the User's Manual for proper wiring.

When wiring and installing the Driver Unit, take appropriate measures not to contaminate it.

4) Storing

Store the Driver Unit in a place at where it is not exposed to rain, water, and harmful gas or liquid.

Store the Driver Unit in the place at where it is not exposed to direct sunlight. Keep the ambient

temperature and the humidity as specified.

5) The limited number of times for overwriting data to EEPROM.

The EEPROM is used to backup all data and programs. However, the number of times for overwriting is

limited to approximately 100 000 times.

2. Precautionary statement for the prolonged use of the Motor

1) Dust-proof and Waterproof of the Motor

The standard Motors are not made for dust-proof or waterproof (IP30 equivalent).

You cannot use the Motor in humid or oily atmosphere.

2) Use conditions

The allowable moment load and axial load depend on the Motor size. Double check the specified limits

of the Motor meet the actual use conditions.

An excessive load or excessive offset load will cause permanent deflection of the rotor and the bearing

abnormality. Be sure not to drop the Motor or not to give an excessive impact to it while transporting it or

installing it.

The flatness of the Motor mounting surface shall be 0.02 mm or less.

3) Periodic check

Puncture of the Motor and shorting or breakage of cable may occur depending on using and environmental

conditions. If the Motor is left in such conditions, it cannot exhibit its capability 100 % and will lead to a

problem of the Driver Unit. We recommend conducting the periodic preventive measures such as an

insulation resistance check of the Motor, to see its current condition.

3. Quick troubleshooting

1) When an alarm occurs

Did you take proper action to the alarm? Follow the remedy described in the manual again.

2) When the power does not turn on and the indication display does not turn on

Check the voltage of main and control power by a tester if the voltage is in the range of specifications that

are described in the User’s manual.

3) When the Motor does not move

Turn off the Motor power and check the followings.

◊ Does the Motor turn smoothly?

◊ Is there any jerky motion?

◊ Does the rotation axis have any axial play?

(Never disassemble the Motor.)

Are the control Inputs and Outputs properly functioning?

◊ Monitor the status of SVON and IPOS signals by the I/O command through the Handy Terminal.

◊ Check if the voltage of input signal and 24 VDC power source are stable using an oscilloscope, etc.

4) The Motor vibrates. Positioning is inaccurate. Alarm of software thermal occurs frequently.

Did you tune the servo parameters LO (Load inertia), SG (Servo gain), VG (Velocity loop proportional

gain), PG (Position loop proportional gain), FP (Primary low-pass filter) and NP (Primary notch filter)?

Are the fixing bolts of the load and the Motor securely fastened? Check and fasten them tightly if

necessary.

Connect the FG terminal of the Driver Unit to one point grounding. (Refer to the User’s Manual for

wiring.)

Is any external force in rotational direction when the Motor is stopping with the Servo lock state? (It leads

to the Motor overheat if external force is applied.)

5) Breaker trip occurs frequently.

When the System recovers from the breaker trip by turning on the power again, take the following action.

◊ Select a breaker of which rated current suits to the power capacity of the Driver Unit.

3.1. Alarm when the power is on

The alarm occurs when the power is turned on if input signals of EMST (Emergency stop, Pin No.3) and

OTP/OTM (Over travel limits, Pin No. 5 and 6) of the connector CN2 are not connected.

However, the Driver Unit is not defective.

This is because the ports of EMST input and OTP/OTM inputs are set to the normally closed contact (B

contact) at the factory.

To cancel the alarm, wire these ports or follow the procedure below to change the polarity to the normally

open contact (A contact).

Step 1: identify the alarm.

1) Turn on the power of the Driver Unit.

2) Check the 7 segments LED on the front panel of the Driver Unit.

◊ The LED changes in order of F→4in case of “Emergency stop.”

◊ The LED changes in order of F→3 in case of “Travel limit over” alarm.

Power LED:Turns on after the power is on. .

Normal: Green

Abnormal: Orange

7segments LED: Identifies a type of alarm.

It indicates a type of alarm in 2 digit

numbers. The numbers will be dispalyed

in time sharing.

If two or more errors occurs, the LED

indicates them in the same manner as

described above.

Powe LED: Turns on after the power is on.

Normal: Green

Abnormal: Orange

When an alarm occurs In normal state

Step 2: Polarity setting of Input ports.

1) Input the command MO (Motor Off) to

make the Motor servo off to set the polarity

of control inputs.

OENT

M:MO

:_

2) Input the command PI0 (Edit input

function). :PI0

FNEMST;_

I ENT

0 ?

P

3) Following the display of the parameter FN

(Function), the parmaeters NW

(Anti-chattering timer) AB (Input polarity)

appear sequentially by a press of SP key,

then the prompt “?” appears on the bottom

line.

FNEMST;

AB1;

NW0.2

?_

SPSP

4) Input the paramter AB0 to change the

polarity to the normally open contact.

After the imput, a prompt “?” appears again,

press the ENT key when the prompt “?”

appears again.

Thus the input EMST is set to the normally

open contact.

?AB0

?

:_

ENT

BA

ENT

0 ?

5) Input the command SV (Servo on) to turn on

the servo of the Motor.. :S

V

:_

VS ENT

◊ When setting the input OTP to the normally closed contact, input the command PI2 and follow

the procedure above.

◊ When setting the input OTM to the normally closed contact, input the command PI3 and follow the

procedure above.

4. Others

Combination of the Motor and the Driver Unit shall conform to the specification.

Be sure to keep the record of parameter settings.

Do not modify the cable set.

Lock the connectors securely and check for loose fixing screw(s).

Please keep expendable parts and backup parts. (The Motor, the Driver Unit and the Cable set for replace)

Use alcohol for cleaning, and never apply thinner.

Conformity with the International Safety Regulations

The Megatorque Motor Systems conform to the EC Directives (CE Marking) and Underwriters Laboratory

(UL) regulations.

Conformity with the EC Directives

The Megatorque Motor System is a machine component that conforms to provisions of the EC Low Voltage

Directive. This will help a user in easy conformity with the EC Directives (CE marking) of a machine into

which the Megatorque Motor System is incorporated.

EMC command (applicable standards: EMI EN55011 and EMS EN61000-6-2)

NSK defined installation models (conditions) for the Megatorque Motor PS/PN Series, including

installation space and wiring between Driver Units and Motors, and set EMC command standards based

on 4 [m] cable models, which have been certified by TÜV.

When Megatorque Motor PS/PN Series is incorporated into machinery, real-world installation and/or

wiring conditions may differ from those of established models. Therefore, it is necessary to check for

EMC command compliance (especially radiation and conduction noise) in the machinery incorporating

the PS/PN Series Motors. Compliance with UL Standards (PS/PN Series only).

Table 1: List of relevant standards for EMC Directive

Item Conformed regulation

Megatorque Motor EN60034-1

EN50178 Low Voltage

Directive

EN55011 : Group1, Class A Conducted noise

EN55011 : Group1, Class A: Radiated noise

EN61000-6-2 : Immunity standard for industrial

environments

EN61000-4-2 : Electro static discharge

EN61000-4-3 : Radio-frequency electromagnetic

field

EN61000-4-4 : Electric fast transit burst

EN61000-4-5 : Lightning surges

EN61000-4-6 : Radio frequency conducted

disturbance

EN61000-4-8 : Power frequency magnetic field

Motor / Driver Unit

EN61000-4-11 : Voltage dips and short interruption

Electromagnetic

Compatibility

Directive

Conditions to Conform with EC Directives

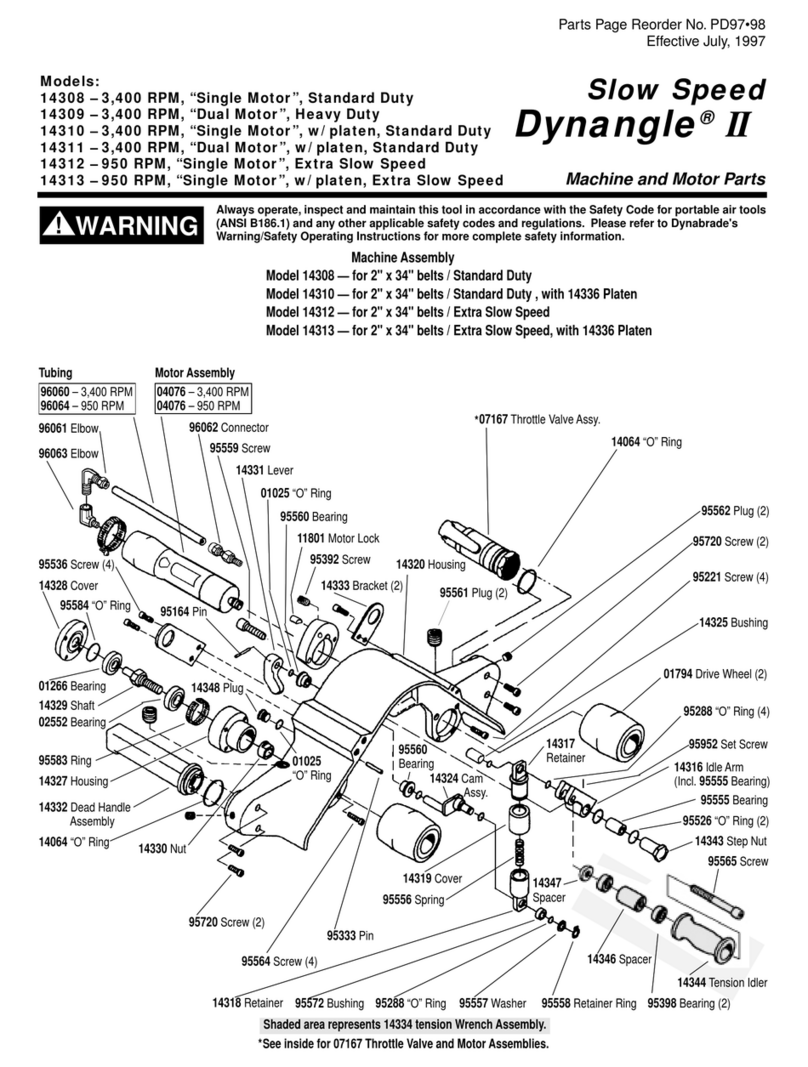

The wiring example shown below is one of our recommendations for the conformity with the EC Directives.

Figure 1: Wiring diagram (Example)

Resolver

EDC Driver Unit

AC power

source

Protective

ground

Main

power

CN5Control

power

CN4

CN3

Noise

filter

Circuit

breaker

L

N

L

N

Inside of

control

panel

CN1

N

N

Handy

Terminal

Ferrite

core 1

(

3 turns

)

Ferrite

core 3

(1 turn)

Ferrite core 3

(2 turns)

Ferrite

core 3

(1 turn)

PS Series

Megatorque Motor

Motor

Surge

absorber

Ferrite

core 2

(

2 turns

)

Environmental conditions

The Driver Unit must be used in the environmental condition of Pollution Degree1 or 2 as specified

by IEC60664-1. The Driver Unit shall be installed into a control panel with the structure that does not

allow penetration of water, oil or dust (IP54).

Power source

The EDC Driver Unit shall be used in the environmental condition of “Over-voltage category III” as

specified by IEC60664-1.

Circuit breaker

Install a circuit breaker that conforms to IEC standard and UL safety standard between the power

source and the Driver Unit.

Noise filter

Install a noise filter between the power source and the Driver Unit.

Ferrite core

Ferrite cores for signal cable shall be set to the power cable, the Motor cable and the resolver cable.

Protective Grounding

Be sure to ground the protective grounding terminal of the EDC Driver Unit to the protective ground

(PE) of the control panel for a measure against electrical shock.

Table 2: List of recommended part

Item Specification Manufacturer Remarks

Circuit breaker Rated current: 15 [A] Single phase: EA32AC-15

(Fuji Electric) Conforms to IEC regulations

and approved by UL

Noise filter Single phase:

250 [VAC], 10 [A] FN2070-10/07

(SCHAFFNER)

Surge absorber – R-A-V781BWZ-4

(Okaya electric)

Ferrite core 1 -E04RA400270150

(Seiwa Electric MFG)

Ferrite core 2 -E04SR301334

(Seiwa Electric MFG) For the Terminal

Ferrite core 3 – E04SR211132

(Seiwa Electric MFG)

Conformity with Underwriters Laboratories Standards

The Megatorque Motor and the EDC Driver Unit are qualified products for the following UL Standard for

safety.

Table 3 Subject Qualified regulation File No.

Megatorque Motor UL1004-1 E216970

Driver Unit UL508C E216221

Conditions to Meet UL Standards

Be sure to meet the following as they are the supplementary conditions for the qualification.

Environmental conditions

The Driver Unit must be used in the environmental condition of Pollution Degree1 or 2 as specified

by IEC60664-1. The Driver Unit shall be installed into a control panel with the structure that does not

allow penetration of water, oil or dust (IP54).

Power source

・ The EDC Driver Unit shall be used in environmental condition of “Over-voltage category III” as

specified by IEC60664-1.

・ Suitable for use on a circuit capable or delivering not more than 5,000 rms symmetrical amperes,

240 [V] maximum.

Circuit breaker

Install a circuit breaker (rated 15[A]) that conforms the UL safety standard between the power source

and the Driver Unit. (Please refer to Table 2 above for the specifications.)

Protective Grounding

Be sure to ground the protective grounding terminal of the EDC Driver Unit to the protective ground

(PE) of the control panel for a measure against electrical shock.

Wiring

・ Use 60/75 [°C] CU wire only (For models except for M-EDC-PN3 and M-EDC-PN4 Series),

Use 75 [°C] CU wire only (For models M-EDC-PN3 and M-EDC-PN4 Series).

・ Wire range for field wiring terminals are marked adjacent to the terminal, on the wiring diagram

or instruction manual.

Table 4: Acceptable lead diameter Wire Range(AWG)

Model No. Input Output

All Models 18 19

Others

・ Solid state motor overload protection level of 115 [%] of FLA is provided in each model.

・ Integral solid state short circuit protection does not provide branch circuit protection. Branch

circuit protection must be provided in accordance with the National Electrical Code and any

additional local codes.

!Caution : - Risk of Electric Shock- Capacitor discharge time is at least 5 [min]

— i —

Contents

1. Introduction------------------------------------1-1

1.1. Notes for Users--------------------------------------------1-2

1.1.1. Notes for Safety -----------------------------------1-2

1.1.2. Precautions for Use -------------------------------1-2

1.1.3. Interchangeability of Motor and Driver Unit

-----------------------------------------------------1-5

1.2. Terminology ------------------------------------------------1-6

2. Specifications ---------------------------------2-1

2.1. System configuration-------------------------------------2-1

2.1.1. Control Mode----------------------------------------2-1

2.1.2. Examples of System Configuration------------2-2

2.2. Referebce Number and Coding -----------------------2-4

2.2.1. PS Series Megatorque Motor-------------------2-4

2.2.2. EDC Driver Unit for

PS Series Megarotque Motor----------------2-4

2.2.3. Cable Set --------------------------------------------2-4

2.2.4. Handy Ternminal-----------------------------------2-4

2.3. Name of Part-----------------------------------------------2-5

2.3.1. PS Series Megatorque Motor-------------------2-5

2.3.2. EDC Driver Unit ------------------------------------2-6

2.3.3. Handy Terminal ------------------------------------2-8

2.4. Standard Combiantion of Motor and Driver Unit

-----------------------------------------------------------------2-9

2.4.1. Motor and EDC Driver Unit Combinations---2-9

2.4.2. Cable Set ------------------------------------------2-10

2.4.3. Handy Teminal -----------------------------------2-10

2.5. Motor Specifications------------------------------------2-11

2.5.1. PS Series Megatorque Motor-----------------2-11

2.5.2. Axial Load and Moment Load-----------------2-12

2.6. External Dimensions -----------------------------------2-13

2.6.1. PS Series Megatorque Motor-----------------2-13

2.6.2. EDC Driver Unit ----------------------------------2-14

2.6.3. Cable Set ------------------------------------------2-16

2.3.6.1 Fixed Use Cable---------------------------2-16

2.3.6.2 Flexible Cable------------------------------2-16

2.7. Driver Unit Specifications -----------------------------2-19

2.8. RS-232C Interface Specifications-------------------2-19

2.8.1. CN1: RS-232C Serial Communication

Connector-----------------------------------2-19

2.8.1.1. CN1 Pin^Out-------------------------------2-19

2.8.1.2. CN1 Signal List----------------------------2-19

2.9. Specifications of Control Input/OutputInter facing

---------------------------------------------------------------2-20

2.9.1. CN2: Control Input/Output Signsl Connector

------------------------------------------------------------- 2-20

2.9.1.1. CN2 Pin-Out -------------------------------2-21

2.9.1.2. CN2 Signal List----------------------------2-22

2.9.2. CN2 Interfacing-----------------------------------2-25

2.9.2.1. General Input Signal---------------------2-25

2.9.2.2. Pulse Train Input Signal ----------------2-26

2.9.2.3. Output Signal------------------------------2-27

2.9.2.4. Position Feedback Signal Output

-----------------------------------------------2-27

2.9.2 5, Analog Monitor Output-------------------2-28

2.10. CN3: Resolver Cable Connector --------------------2-29

2.10.1. CN3 Pin-Out-------------------------------------2-29

2.10.2. CN3 Signal List ---------------------------------2-29

2.11. CN4: Motor Connector -------------------------------2-30

2.11.1. CN4 Pin-Out-------------------------------------2-30

2.11.2. CN4 Signal List ---------------------------------2-30

2.12. CN5: Connector for Power Supply ----------------2-31

2.12.1. CN5 Pin-Out-------------------------------------2-31

2.12.2. CN5 Wiring Diagram---------------------------2-31

3. Unpacking, Installation and Wiring ------3-1

3.1. Unpacking-------------------------------------------------- 3-1

3.1.1. Receiving Check ---------------------------------- 3-1

3.1.2. Motor and EDC Driver Unit Combinations-- 3-1

3.2. Installation-------------------------------------------------- 3-2

3.2.1. Motor Mounting------------------------------------ 3-2

3.2.1.1. Environmental Conditions of Motor

------------------------------------------------ 3-2

3.2.1.2. Motor Installation--------------------------- 3-2

3.2.1.3. Coupling Load to Motor ------------------ 3-3

3.2.1.4. Confirmation of Use Conditions-------- 3-3

3.2.1.5. Dummy Inertia------------------------------ 3-3

3.2.2. Installation of Driver Unit------------------------ 3-4

3.3. Wiring ------------------------------------------------------- 3-5

3.3.1. Cable Set-------------------------------------------- 3-5

3.3.2. Connecting Power -------------------------------- 3-6

3.3.3. Ground Connection------------------------------- 3-7

3.3.4. Connector Wiring---------------------------------- 3-8

3.3.4.1. Wiring Example (CN2)-------------------- 3-9

3.4. Power on --------------------------------------------------3-10

3.4.1. Precautions Before Power on-----------------3-10

3.4.2. Points to Be Checked when Power on -----3-11

3.4.3. Polarity Setting

(Normally Open Contact and Normally Closed

Contact)--------------------------------------------3-12

3.4.4. Power on and Servo on ------------------------3-13

4. Handy Terminal communication----------4-1

4.1. Cehck on Handy Terminal ----------------------------- 4-2

4.2. Parameter Setting---------------------------------------- 4-2

4.2.1. Input of the Password---------------------------- 4-2

4.2.2. Reset to Shippong Set--------------------------- 4-3

4.3. Monitoring Parameter ----------------------------------- 4-3

4.3.1. Monitoring Parameters by a Group----------- 4-4

4.3.2. Monitoring Parameters Altered

from Shipping Set ------------------------------- 4-4

4.4. Monitoring Current Status------------------------------ 4-5

4.4.1.Inputting a Command while Monitoring Multiple

Conditions ------------------------------------------4.5

— ii —

5. Tuning ------------------------------------------5-1

5.1. Tuning Flowchart------------------------------------------5-1

5.2. Tuning Level 1: Automatic Tuning--------------------5-2

5.2.1. Precaustions for Automatic Tuning------------5-3

5.2.2. initilization of Servo Parameters ---------------5-4

5.2.3. Automatic Tuning ----------------------------------5-5

5.2.4. Trial Running----------------------------------------5-7

5.3. Tuning Level 2: Servo Gain Tuning ------------------5-9

5.3.1. Input of Load Inertia-------------------------------5-9

5.3.1.1. When Load Inertia Is Unknown ---------5-9

5.3.2. Minor Tuning of Servo Gains -----------------5-10

5.4. Tuning Level 3: Manual Tuning----------------------5-13

5.4.1. Precautions for Manual Tuning---------------5-13

5.4.2. Setting Velocity Loop

Proportional Gain (VG) ------------------------5-13

5.5. Setting Filters (Tuning Level 2)----------------------5-15

5.5.1. Setting Low-pass Filter-------------------------5-15

5.5.2. Setting Notch Filter------------------------------5-16

6. Operation---------------------------------------6-1

6.1. Preparation -------------------------------------------------6-1

6.1.1. Wiring Check----------------------------------------6-1

6.1.2. Operation Procedure------------------------------6-1

6.2. Position Scale----------------------------------------------6-2

6.2.1. Resolution of Position Scale --------------------6-2

6.2.2. Position of Position Scale------------------------6-3

6.2.3. Setting of Home Position-------------------------6-4

6.2.4. Software Over Travel Limit----------------------6-6

6.2.4.1. Setting Limits by Teaching ---------------6-7

6.2.4.2. Setting Limits by Direct Input------------6-8

6.3. Positioning Operation-----------------------------------------6-9

6.3.1. Positioning Command ----------------------------6-9

6.3.2. Program Positioning Operation---------------6-10

6.3.2.1. Program Positioning Operation via

Control Inputs and Outputs -----------6-12

6.3.2.2. Program Positioning Operation

via RS-232C Communication --------6-14

6.3.2.3. Programming ------------------------------6-15

6.3.2.4. Program Sequence ----------------------6-20

6.3.3. Pulse Train Command Positioning Operation --

-------------------------------------------------------6-23

6.3.3.1. Format of Pulse Train Input------------6-26

6.3.3.2. Resolution of Pulse Train---------------6-27

6.3.3.3. Input Timing--------------------------------6-28

6.3.4. Jogging---------------------------------------------6-29

6.3.4.1. Jogging with Control Input and Output

------------------------------------------------6-30

6.3.4.2. Jogging via RS-232C Communication

------------------------------------------------6-31

6.3.5. RS-232C Communication Positioning

Operation ------------------------------------------6-32

7. General Function-----------------------------7-1

7.1. Control Input----------------------------------------------- 7-1

7.1.1. Emergency Stop: EMST------------------------- 7-1

7.1.2. Alarm Clear: ACLR ------------------------------- 7-2

7.1.3. Hardware Over Travel Limit: OTP andOTM-----

--------------------------------------------------------- 7-3

7.1.4. Servo on: SVON----------------------------------- 7-4

7.1.5. Program Start: RUN

Internal Program Channel Selection: PRG0 to 7

7-6

7.1.6. Stop: STP------------------------------------------- 7-7

7.1.7. Jogging: JOG

Jog Direction: DIR-------------------------------- 7-9

7.2. Control Output -------------------------------------------7-10

7.2.1. Driver Unit Ready: DRDY----------------------7-10

7.2.2. Warning: WRN------------------------------------7-10

7.2.3. Over Travel Limit: OTPA and OTMA--------7-11

7.2.4. Servo State: SVST-------------------------------7-13

7.2.5. In Operation: BUSY -----------------------------7-14

7.2.6. In-position: IPOS---------------------------------7-15

7.2.6.1. CFIN Mode (Parameter FW < 0)------7-16

7.2.6.2. IPOS Mode (Parameter FW = 0)------7-17

7.2.6.3. FIN Mode (Parameter FW > 0)--------7-18

7.2.6.4. Parameter IN: In-position Limit--------7-19

7.2.6.5. In-position Stability Timer:

Parameter IS------------------------------7-19

7.2.7. Target Proximity: NEARA and NEARB -------7-20

7.2.8. Position Feedback Signal----------------------7-21

7.2.8.1. Resolution of Position Feedback Signal

-------------------------------------------------7-22

7.2.8.2. Signal Output Timing---------------------7-24

7.3. RS-232C Monitor----------------------------------------7-25

7.3.1. Monitoring Way for Control Input/Output Signal

--------------------------------------------------------7-26

7.3.1.1. Electric Condition Monitor: Monitor IO0

-------------------------------------------------7-27

7.3.1.2. Monitor for Internal Recognition of Input

and Output State: Monitor IO1 --------7-28

7.3.1.3. Monitor for State of Input Functions:

Monitor IO2---------------------------------7-28

7.3.1.4. Monitor for State of Output Functions:

Monitor: IO3--------------------------------7-29

7.3.1.5. Monitor for Individual Function --------7-29

7.3.2. Alarm Monitor-------------------------------------7-30

7.3.2.1. Monitor for All Occurring Alarmas

at Once--------------------------------------7-30

7.3.2.2. Monitor for Alarm History and Event:

Monitor TA?HI----------------------------7-31

7.3.3. Pulse Train Counter: Monitor RP ------------7-32

7.3.4. Position Feedback Signal Counter:

Monitor FK-----------------------------------------7-32

7.3.5. Current Position Monitor: Monitor TP-------7-32

7.3.6. Software Thermal Loading Monitor: Monitor TJ

--------------------------------------------------------------7-33

— iii —

7.4. Analog Monitor-------------------------------------------7-34

7.4.1. Use of Preset Monitor---------------------------7-35

7.4.2. Customization of Monitor Data ---------------7-36

7.4.2.1. Analog Monitor for State of Control Inputs

and Outputs Functions -----------------7-37

8. More Advanced Function ------------------8-1

8.1. Assignment of Input/Ouput Function-----------------8-1

8.1.1. Function of Input -----------------------------------8-2

8.1.2. Funciton of Control Outpurt ---------------------8-4

8.1.3. Edit of function of Control Input and Output

---------------------------------------------------------8-6

8.1.3.1. Edit of Control Input Function -----------8-6

8.1.3.2. Edit of Control Ouput Function----------8-8

8.1.3.3. Masking of Control Output Function

------------------------------------------------8-10

8.1.3.4. Forcible Change in Setting of Output

Port Function -----------------------------8-11

8.2. Extended Control Input--------------------------------8-12

8.2.1. Input HOLD: HLD--------------------------------8-12

8.2.2. Velocity Override: ORD ------------------------8-13

8.2.3. Integration OFF: IOFF--------------------------8-14

8.2.4. Home Return Start: HOS ----------------------8-15

8.2.5. Home Position Limit: HLS ---------------------8-15

8.3. Extended Control Output------------------------------8-16

8.3.1. In-zone Output: ZONEA, ZONEB,

and ZONEC -------------------------------------8-16

8.3.2. Outputs of Operating Conditions -----------8-17

8.3.2.1. Position Error: TEU (Position Error,

Under) and TEO (Position Error, Over)

------------------------------------------------8-18

8.3.2.2. Velocity: Outputs TVU (Velocity, Under)

and TVO (Velocity, Over)--------------8-19

8.3.2.3. Torque Command: Outputs TTU (Torque

Command, Under) and TTO (Torque

Command, Over)--------------------------8-19

8.3.2.4. Thermal Loading: Outputs TJU (Thermal

Loading, Under) and TJO (Thermal

Loading, Over)-----------------------------8-20

8.3.3. Travel Limit Output (±): OTXA----------------8-21

8.3.4. Output Normal: NRM----------------------------8-22

8.3.5. Home Return Completed: HOME------------8-22

8.3.6. Home Position Defined: HCMP --------------8-22

8.4. Teaching --------------------------------------------------8-23

8.4.1. Preparation for Teaching-----------------------8-24

8.4.2. Teaching of Parameter-------------------------8-24

8.4.3. Teaching the Position Data of Positioning

Program -------------------------------------------8-25

8.5. 8.5. Tuning------------------------------------------------8-26

8.5.1. Servo Block Diagram ---------------------------8-26

8.5.2. Digital Filter----------------------------------------8-28

8.5.3. Position Loop Dead Band----------------------8-29

8.5.4. Automatic Gain Switching ---------------------8-30

8.6. Positioning Operation ----------------------------------8-31

8.6.1. Acceleration Profiling and Individual

Acceleration Setting------------------------------8-31

8.6.2. Examples of Acceleration Profiling and

Individual Setting of Acceleration and

Deceleration --------------------------------------8-33

8.6.3. Shorter Way Positioning------------------------8-34

8.6.4. User Scale Positioning--------------------------8-36

8.7. Program Operation -------------------------------------8-39

8.7.1. Change of Parameter via Program Operation

--------------------------------------------------------8-39

8.7.2. Automatic Program Execution at Power on

--------------------------------------------------------8-41

8.8. Home Return ---------------------------------------------8-45

8.8.1. Home Return Operation via the Home Position

Sensor----------------------------------------------8-47

8.8.1.1. Home Return Mode: OS4---------------8-47

8.8.1.2. Home Return Mode: OS5---------------8-49

8.8.1.3. Home Return Mode: OS1---------------8-49

8.8.1.4. Home Return Mode: OS3---------------8-49

8.8.2. Home Return with Travel Limit ---------------8-50

8.8.2.1. Home Return Mode: OS7---------------8-50

8.8.3. Teaching of Home Position--------------------8-51

8.8.3.1. Home Return Mode: OS6---------------8-52

8.8.3.2. Teaching of Home Position in

Servo-off Sate------------------------------8-53

8.8.4. Position Adjustment of Home Limit Sensor

--------------------------------------------------------8-54

8.8.5. Teaching of Home Position Offset-----------8-55

8.9. RS-232C Communication-----------------------------8-56

8.9.1. Specifications of Communication ------------8-56

8.9.2. Communication Procedure --------------------8-56

8.9.2.1. Power on------------------------------------8-56

8.9.2.2. Command Entry---------------------------8-57

8.9.2.3. Cancelling Command--------------------8-58

8.9.2.4. Input of the Password--------------------8-58

8.9.2.5. Readout of Parameter Settings and

Internal State-------------------------------8-59

8.9.2.6. Reading out Parameter Settings by a

Group-----------------------------------------8-60

8.9.2.7. Error Message-----------------------------8-61

8.9.3. Communication with Personal Compute ---8-62

8.9.3.1. Setup of Hyper Terminal----------------8-62

8.9.3.2. Backup of Parameter --------------------8-63

8.9.3.3. Restoring Parameters -------------------8-64

— iv —

9. Details of Command and Parameter----9-1

9.1. Handling Instruction of Command and Parameter

-----------------------------------------------------------------9-1

9.1.1. Character String of Command------------------9-1

9.1.2. Grammar of Command -------------------------9-1

9.1.3. Error Message--------------------------------------9-2

9.1.4. Multi-statement on a Line------------------------9-2

9.1.5. Wildcard Search------------------------------------9-3

9.1.6. Repeating Readout--------------------------------9-3

9.1.7. Multi-monitor ----------------------------------------9-4

9.1.8. Initialization of Specified Parameter-----------9-4

9.1.9. Adjusting ---------------------------------------------9-5

9.1.10. Output to Analog Monitor-----------------------9-5

9.2. Glossary of Command and Parameter --------------9-6

9.3. Parameter List -------------------------------------------9-85

10. Maintenance-------------------------------10-1

10.1. Backup Parts -------------------------------------------10-1

10.2. Storing the Parts---------------------------------------10-1

10.3. Periodic Check-----------------------------------------10-2

10.3.1. Motor ----------------------------------------------10-2

10.3.2. Driver Unit

(Including Cables and Handy Terminal)

-------------------------------------------------------10-2

10.4. Periodic Replacement of Parts---------------------10-3

10.4.1. Motor ----------------------------------------------10-3

10.4.2. Cables---------------------------------------------10-3

10.4.3. Driver Unit----------------------------------------10-4

10.5. Repair Service -----------------------------------------10-6

10.6. Warranty Period and Covering Range-----------10-6

10.6.1. Warranty Period --------------------------------10-6

10.6.2. Limited Warranty -------------------------------10-6

10.6.3. Immunities ---------------------------------------10-6

10.6.4. Service Fee--------------------------------------10-6

10.6.5. Notice for discontinuity of the Product and

Duration of Support ---------------------------10-6

11. Alarm and Warning ----------------------11-1

11.1. Identifying Alarm and Warning---------------------11-1

11.1.1. LED Alarm Indicator---------------------------11-1

11.1.2. Confirmation of Alarm and Warning-------11-2

11.1.3. History of Alarm and Warning---------------11-3

11.2. List of Alarm and warning ---------------------------11-5

11.2.1. Normal State ------------------------------------11-5

11.2.2. Condition in the State of Alarm and Warning -

-------------------------------------------------------11-6

11.2.2.1. Alarm---------------------------------------11-6

11.2.2.2. Warning -----------------------------------11-7

11.2.2.3. Over Travel Limit------------------------11-7

11.3. Cause and Remedy-----------------------------------11-8

11.3.1. CPU Error----------------------------------------11-8

11.3.2. Alarm A0: Disconnected Sensor Cable---11-8

11.3.3. Alarm A1: Position Data Error---------------11-9

11.3.4. Alarm A2: Motor Cable Disconnected-----11-9

11.3.5. Warning A3: Software Thermal----------- 11-10

11.3.6. Alarm A4: Excess Velocity -----------------11-11

11.3.7. Warning A5: Home Position Undefined-11-11

11.3.8. Alarm A7: Resolver Amplifier Alarm -----11-12

11.3.9. Alarm A9: Commutation Error-------------11-12

11.3.10. Warning C0: Position Command/Feedback

Signal Error ----------------11-13

11.3.11. Alarm C3: CPU Error-----------------------11-13

11.3.12. Alarm E0: RAM Error ----------------------11-14

11.3.13. Alarm E2: ROM Error----------------------11-14

11.3.14. Alarm E7: System Error-------------------11-15

11.3.15. Alarm E8: Interface Error -----------------11-15

11.3.16. Alarm E9: ADC Error-----------------------11-15

11.3.17. Warning F1: Excess Position Error-----11-16

11.3.18. Over Travel F2: Software Over Travel Limit -

------------------------------------------------------11-17

11.3.19. Over Travel F3: hardware Over Travel Limit-

------------------------------------------------------11-18

11.3.20. Alarm F4: Emergency Stop---------------11-19

11.3.21. Warning F5: Program Error --------------11-19

11.3.22. Warning F8: Automatic Tuning Error---11-20

11.3.23. Warning P0: Over Heat--------------------11-21

11.3.24. Alarm P1: Main Power Overvoltage----11-21

11.3.25. Alarm P2: Motor Over Current-----------11-22

11.3.26. Alarm P3: Control Power Under Voltage

------------------------------------------------------11-22

11.3.27. Warning P5: Main Power Under Voltage

------------------------------------------------------11-23

11.3.28. Alarm P9: Power Module Alarm---------11-23

12. Troubleshooting -------------------------- 12-1

12.1. Identifying Problem------------------------------------12-1

12.2. Troubleshooting----------------------------------------12-1

12.2.1. Power Trouble-----------------------------------12-2

12.2.2. Motor Trouble------------------------------------12-2

12.2.3. Vibration, Abnormal Noise or Unstable Settling

--------------------------------------------------------12-3

12.2.4. Improper Positioning---------------------------12-3

12.2.5. Communication Problem ---------------------12-4

Appendix

Appendix 1: How to Monitor Input and Output Signal-A-1

Appendix 2: How to Check Motor Condition-------------A-5

Appendix 3: How to Back up and Restore the Settings of

Programs and Parameters ------------------A-8

Appendix 3.1. When Using the Handy Terminal

FHT21-------------------------------------A-8

Appendix 3.2. When Using a Personal Computer

------------------------------------------------ A-11

Appendix 3.3. Back up Manually -------------------- A-14

Appendix 4: Procedure for Replacing EDC Driver Unit

-------------------------------------------------------------- A-16

Appendix 5: Dump Resistor-------------------------------- A-18

Appendix 6: Wiring of RS-232C Communication Cable---

-------------------------------------------------------------- A-20

Appendix 7: Setting List of Parameter and Program of

EDC Driver Unit ------------------------------ A-21

— 1-1 —

1. Introduction

This is the operation manual of the Megatorque Motor System with EDC Driver Unit. Please

refer to “2.4. Standard Combination List” for the applicable Megatorque Motor System.

Before operating the Megatorque Motor System for the first time, this manual should be read

thoroughly.

We describe the standard PS series Motors only in “2.5. Motor Specifications.” If your Motor is

not one of these, please refer to the attached specification document.

1.1. Notes to Users

1.1.1. Notes for Safety

For your safety, you should read this manual thoroughly and understand the contents before

operating the Megatorque Motor System.

The following notices are added to give particular emphasis on the safety precautions in this

manual.

!Danger : A matter that might cause serious injuries.

!Warning : A matter that might result in injuries.

!Caution : A matter that might result in the breakdown of equipment into which the

Motor is installed or the break down of the mechanism surrounding the

Motor.

1.1.2. Precautions for Use

Pay special attention to the following when installing, checking and troubleshooting the

Megatorque Motor System.

!Caution : When making a combination of a Motor and a Driver Unit, confirm that

their specifications for Motor size and maximum Motor torque match

each other.

• This is because the Driver Unit holds the unique parameter settings for a

matching Motor.

• Refer to “2.4.Standard Combination List” for the combination.

• Make sure that the reference numbers on each identification plate of a Motor

and a Driver Unit indicate the same coding for Motor size, Motor maximum

torque and position sensor.

• If the reference numbers are not matched, the Motor may lose its accuracy and

emit noise, and furthermore, it may not move or lose its control.

!Caution : Do not cut the Cable Set, or do not hook it up to other cable.

• The modification of the Cable Set may worsen the Motor and Driver Unit

performances, typically positioning accuracy and repeatability of the resolver.

!Caution : Never disassemble the Motor because it has been precisely assembled

and tuned.

• If disassembled, it may cause abnormalities such as deterioration in rigidity

and positioning accuracy, and generation of noise.

— 1-2 —

!Danger : Be sure to connect the Emergency Stop signal circuit to the EMST port

of the CN2 control I/O connector.

• Please set the System so that you can immediately stop the Motor in case of an

emergency.

!Caution : Do not remove the panel of the Driver Unit so as not to cause an

electric shock. It is extremely dangerous due to high voltage present.

• Driver Units have high capacity electrolytic capacitors in its internal circuits,

and thus resulting in high residual voltage of the capacitors for few minutes

after the main power is turned off.

!Danger : Do not place other objects in the path of the Motor when the Motor

power is on. An unexpected motion of the Motor may result in injury

and/or damage to the System or other mechanism.

!Danger : Always stay in a safe place away from the operating area of the Motor

when the System is powered on.

!Danger : If the Motor is fitted with an arm or similar devices, take extra care to

assure that no obstacles are in or around the Motor work area.

!Caution : Use of an optional dump resistor shall be considered for a heavy-duty

operation.

• The Megatorque Motors regenerate when they decelerate carrying heavy load

inertia.

• An internal capacitor charges the Motor regeneration. However, when high

and continuous regeneration exceeding its capacity is applied, excess energy

activates an alarm “Alarm P1: Abnormal main power voltage” and the Motor

stops.

• In such a case, you need to decrease velocity, deceleration rate, and operation

duty cycle, or you require an external high capacity dump resistor.

!Danger: Never apply water or oil to the Driver Unit.

• Take appropriate measures to protect the Driver Unit from water, oil, slag,

dust, and corrosive gas.

Figure 1-2: EDC Driver Unit

— 1-3 —

!Warning : Do not test the insulation of the Driver Unit.

• The high voltage used in the test may destroy the internal circuits of Driver

Unit.

!Caution : In most cases, the Direct Drive Motor System cannot exhibit its full

performance unless the shipping set of the parameters is altered for

actual applications.

• Refer to “5. Tuning” and be sure to set the servo parameters to actual use

conditions.

!Caution : Allowable moment load and axial load depend on Motor size. Please

confirm that actual load conditions are in the limits of the Motor.

• Refer to “2.5. Motor Specifications” for the allowable moment load, axial load

and radial load.

!Caution : An excessive eccentric load or an excessive load may cause the

permanent deformation of the rotor or premature failure of the bearing

inside the Motor. When handling the Motor, please pay special

attention not to drop it and not to give a shock to it. Protect the Motor

from a collision with an obstacle.

• Excessive load to the Motor may damage the bearing of Motor and may

mechanically lock the Motor.

• The flatness of the Motor mounting surface shall be 0.02 mm or less.

!Caution : For an oscillating operation less than 45 [°], turn the Motor 90 [°] or

more at least once a day.

!Caution : Do not give a direct impact to the Motor with a hammer or the like. A

direct impact to the outside of the Motor or the load fixed to the Motor

may deteriorate accuracy of the built-in position sensor.

!Caution : When attaching a rotary machine component to the Motor such as a

bearing or a ball screw, be sure to align both centers within 0.01 mm.

Excessive eccentric load or excessive load to the Motor may cause the

premature failure of Motor’s bearing.

!Warning

:

Be sure not to activate the dynamic brake in the following conditions.

Otherwise the dynamic brake circuit may break and the Motor will

enter in a “free run” state, leading to possible injuries.

◊ Do not activate the dynamic brake in normal operations. Stop the Motor by a control

command, not by the dynamic brake. The dynamic brake is an auxiliary function to

stop the Motor immediately in an emergency. In the middle of operation, an alarm, a

warning or the “Emergency stop” input activates the dynamic brake.

• Warnings that initiate “Servo-off” state are “A3” (Software thermal), “C0”

(Position command/Feedback error), “C5” (Field bass error), “F5” (Program

error), and “F8” (Automatic tuning error).

— 1-4 —

◊ The load moment of inertia to a Motor must be 70 times or less than the Motor inertia

(100 times for the PS1, PS3 and PN2 type Motors). In case of an indexing operation, a

position command shall be 360 degrees or less, while the maximum speed for

continual rotation must be 0.5 [s-1] or less.

(However, there may be a possibility to exceed the above limits in some cases. Please

consult NSK when you require a close investigation on the limits.)

◊ For the PN4180 Motor, be sure to stop the Motor for 20 minutes or longer when you

stop it by the dynamic brake.

!Caution: When the Motor is continually accelerating a high inertial load with high

acceleration, the system constantly outputs a high torque exceeding

the rated torque, and thus likely to activate the warning “A3” (Software

thermal). In such a case take a remedy to decrease the load moment

of inertia or to lower the speed.

— 1-5 —

1.1.3. Interchangeability of Motor and Driver Unit

Interchangeable types

The standard Motors and the EDC Driver Units can be randomly matched (interchangeable).

You may have a combination of a Motor and a Driver Unit that have the different serial number.

However, please refer to “2.4. Standard Combination List” for combination of reference

numbers of the Motors, the Driver Units and the Cable Sets.

Non-interchangeable types

The interchangeability of the Motors and the Driver Units won’t be applicable for a Megatorque

Motor System that is made to a special order. In such a case please refer to respective

specification documents.

Be sure to make a combination of a Motor and a Driver Unit with the same serial number when

they are not interchangeable. Moreover, you must use the specified Cable Set.

Please be aware that the Megatorque Motor System won’t fully exhibit its performance as

described in its specifications if a Motor and a Driver Unit are matched with different serial

number, or if you change the length of the Cable Set. Especially in case of a System that

incorporates an absolute position sensor, you may lose positioning repeatability of the Home

position.

— 1-6 —

1.2. Terminology

It is necessary to be familiar with some terms used in this document.

Cable Set A cable set exclusive use for the Megatorque Motor System. Connects driver Unit and

Megatorque Motor

CCW Counterclockwise; direction of Motor rotation. Seen from the top of rotor.

closed Logic output state; output current will flow.

count/rev. Count/revolution. A unit of resolution. In some cases, it is described as pulse/rev. in this

manual.

CW Clockwise; direction of Motor rotation. Seen from the top of rotor.

Driver Unit Means Megatorque Motor System’s driver unit when capitalized.

Handy Terminal Means an optional handy terminal (M-FTH21) for RS-232C communication. Exclusive

use for Megatorque Motor System. .

LO A parameter to set a load inertia moment to the Motor. Unit is in [kg•m2].

Motor Means Megatorque Motor System’s motor when capitalized.

OFF (all capital) Logic input state; input will see an open circuit.

ON (all capital) Logic input state; there will be a current path to the common DC supply.

open Logic output state; no output current

servo-lock One typical state of servo-on; the Motor provides torque and remains in position.

servo-off The state where the Driver Unit provides no current to the Motor, and the Motor provides

no torque. The Motor rotor can be rotated easily.

servo-on The state that the Driver Unit is ready to control the Motor, or is controlling the Motor.

shipping set A parameter setting or a Driver Unit function setting at shipping.

System Means Megatorque Motor System when capitalized.

velocity gain (VG)

Shorter name for velocity loop proportional gain.

The velocity error, the deviation of velocity feedback from the velocity command, will be

amplified by a number defined as a velocity gain set by the parameter VG, and will be

output as a torque command.

The following commands are used for the Driver Unit to set function and to execute

operation.

Command:

Execution instruction to the Driver Unit. It includes the command RUN to start positioning

operation and stop commands to stop positioning operation.

Parameter:

The parameters hold the operational settings of internal function of the Driver Unit. Changing of

these settings enables to move the Motor as planed

◊ Global parameter:

A parameter set to a command line in program channels. This term is used to

distinguish them from local parameters. It is stored in a non-volatile memory.

◊ Local parameter:

A parameter that is temporarily becomes effective in a program operation. It is not

stored to a non-volatile memory.

Monitor

A monitor holds the internal state of the Driver Unit, such as Motor velocity and position scale

data. You can monitor them anytime.

Table of contents

Other NSK Engine manuals

Popular Engine manuals by other brands

Briggs & Stratton

Briggs & Stratton Vanguard 470000 Series Operating and maintenance instructions

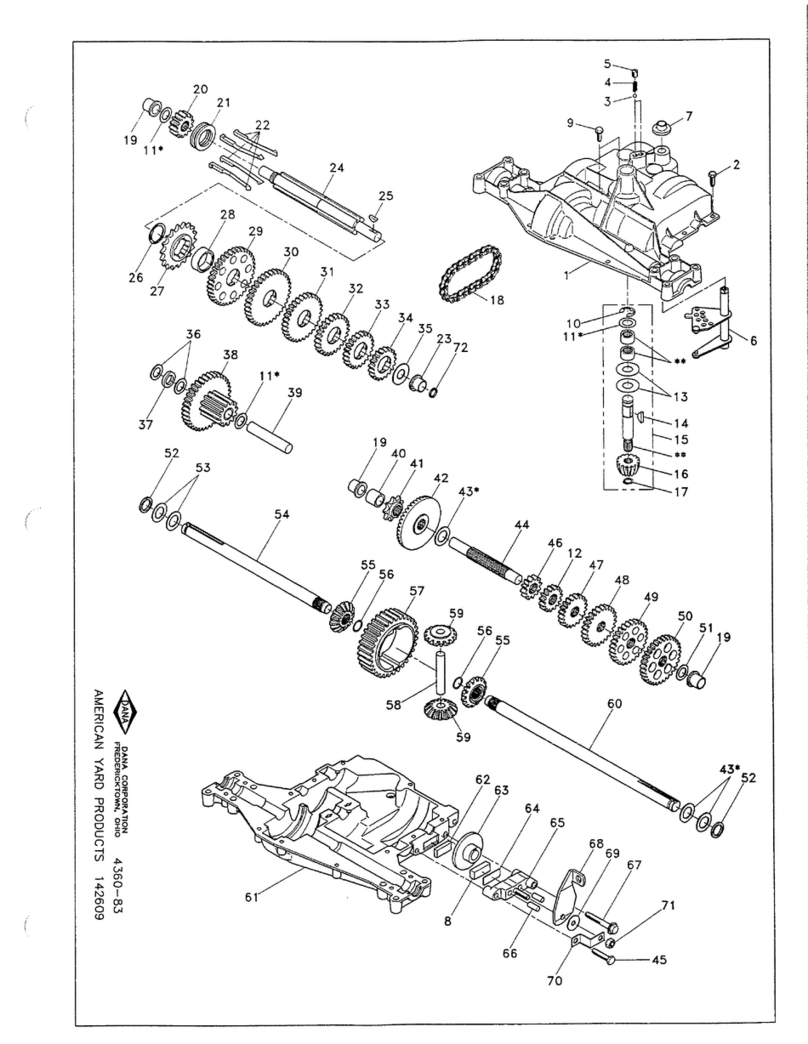

DANA

DANA 4360-83 parts list

Mack

Mack MP8 Body builder instructions

Kohler

Kohler Lombardini SILEO 1000 Use & maintenance

Black Bruin

Black Bruin BB series General Instructions for Use

Rotax

Rotax 377 UL Repair manual