2

NSK linear guides are high quality and are

easy to use. NSK places importance on safety

in design. For maximum safety, please follow

precautions as outlined below.

(1) Lubrication

a. Remove the rust preventative rail-coating

before installation. If you are using oil as

a lubricant, consult NSK for compatibility

issues with the pre-packed factory grease.

(2) Handling

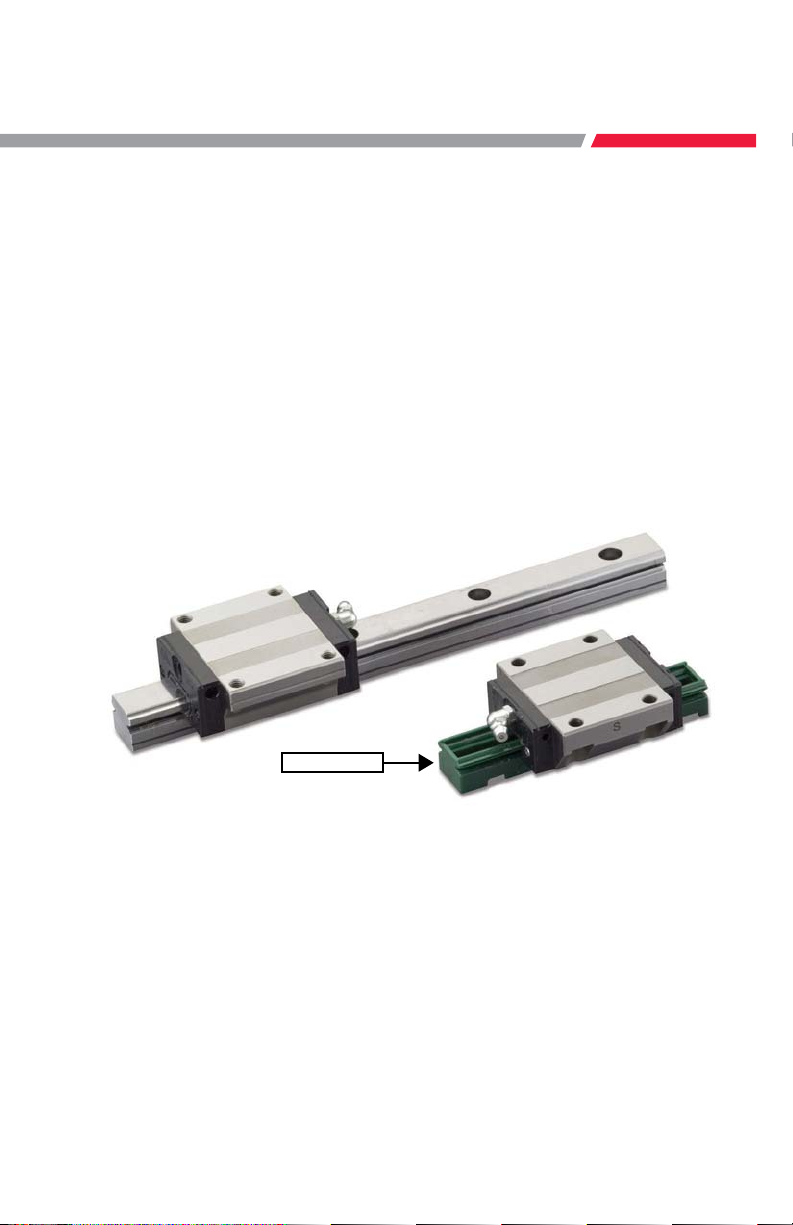

a. Interchangeable ball slides (randomly

matching types between rail and ball

slide) are installed to the provisional rail

when they leave the factory. Handle the

ball slide with care during installation to

the rail.

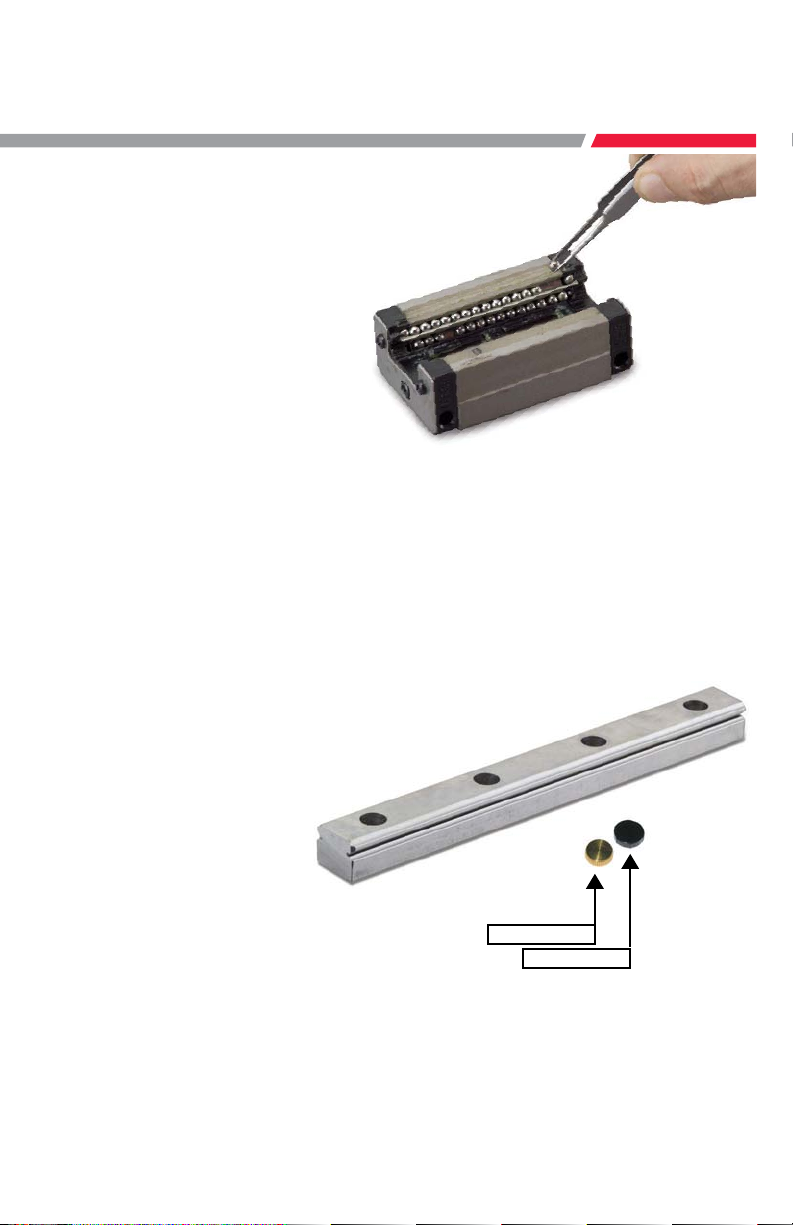

b. Do not disassemble the guide unless

absolutely necessary.

c. Ball slide will move easily. Make sure that

the ball slide does not disengage from the

rail.

d. Standard end cap is made of plastic and

may break if a direct force is applied.

(3) Precautions in use

a. Make every effort not to allow dust and

foreign objects to enter.

b. The temperature of the place where

linear guides are used should not exceed

80˚C (excluding heat-resistant type linear

guides.) A higher temperature may

damage the plastic end cap.

c. If the user cuts the rail, thoroughly

remove burrs and sharp edges on the cut

surface.

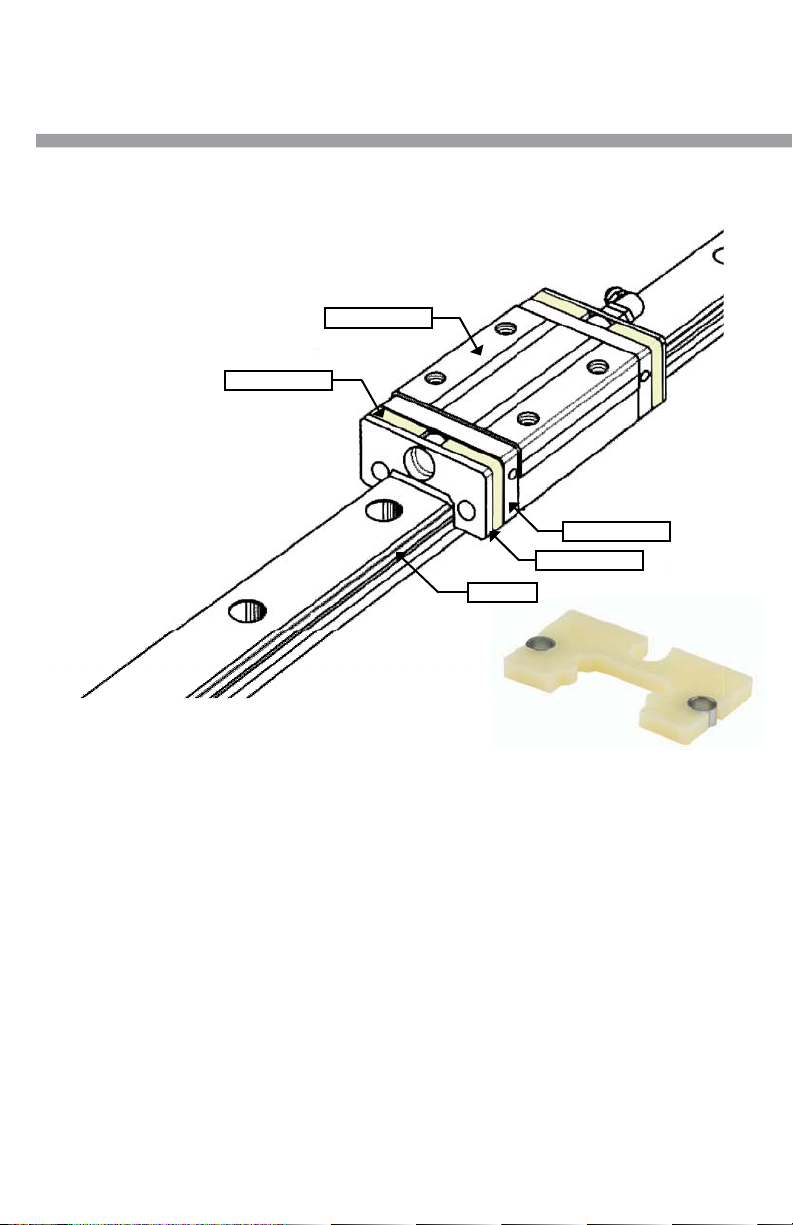

d. When hanging upside-down (e.g. the rail

is installed upside-down on the ceiling

in which the ball slide faces downward),

should the end cap be damaged, causing

the balls to fall out, the ball slide may be

detached from the rail and fall. For such

use, take measures including installing a

safety device.

(4) Storage

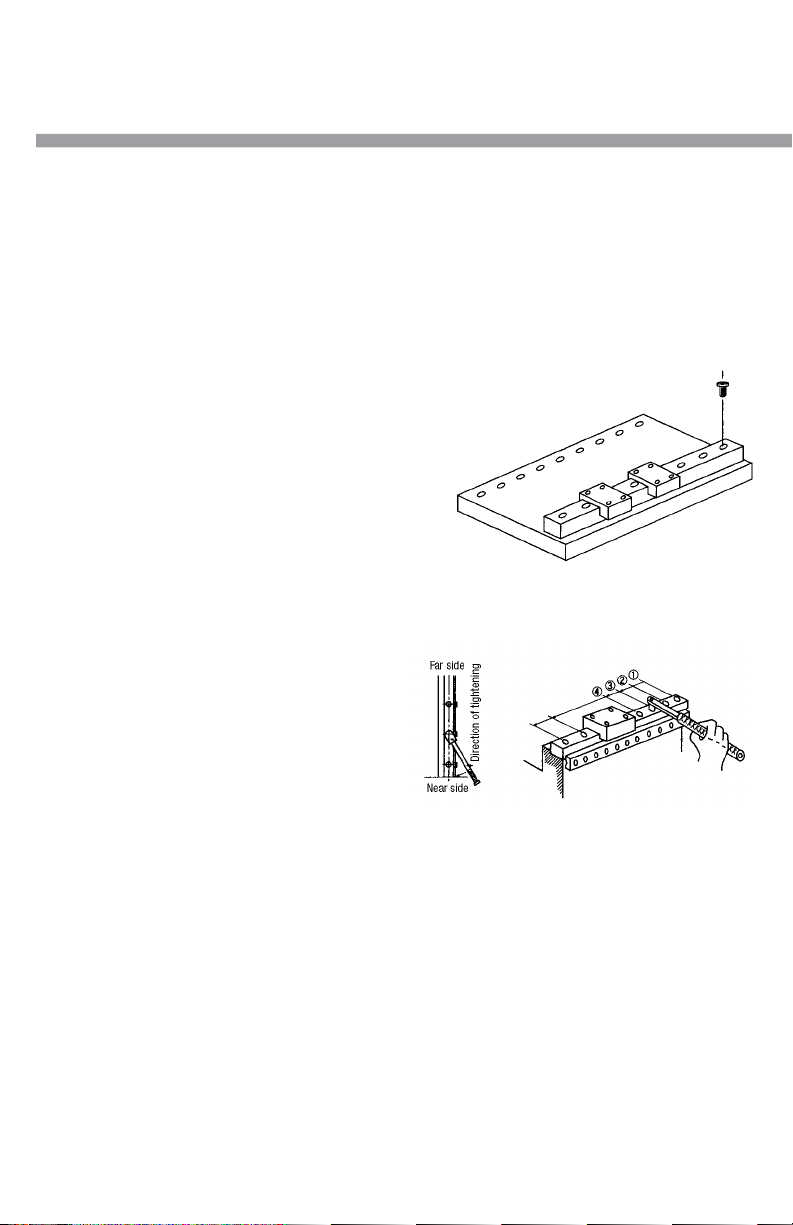

a. Linear rail may bend if stored

inappropriately. Place it on a suitable

surface, and store it in a flat position.

Confirm lubrication.

Handle with care.

Do not drop.

Do not disassemble.

Do not contaminate.

Do not hang upside down.

Temperature limitation.

Store in the correct position.

Do not use direct force.

Linear Guide: Handling Precautions