2. Matters to be attended to use the Motor of the Megatorque Motor System

l ------ For prolonged use of the Megatorque Motor ------

1Dustproof and Waterproof of the Motor

l Make sure how your Motor is graded for dust-proof and/or waterproof. You cannot use the Megatorque

Motor in the environment where chemicals or paint fumes exist.

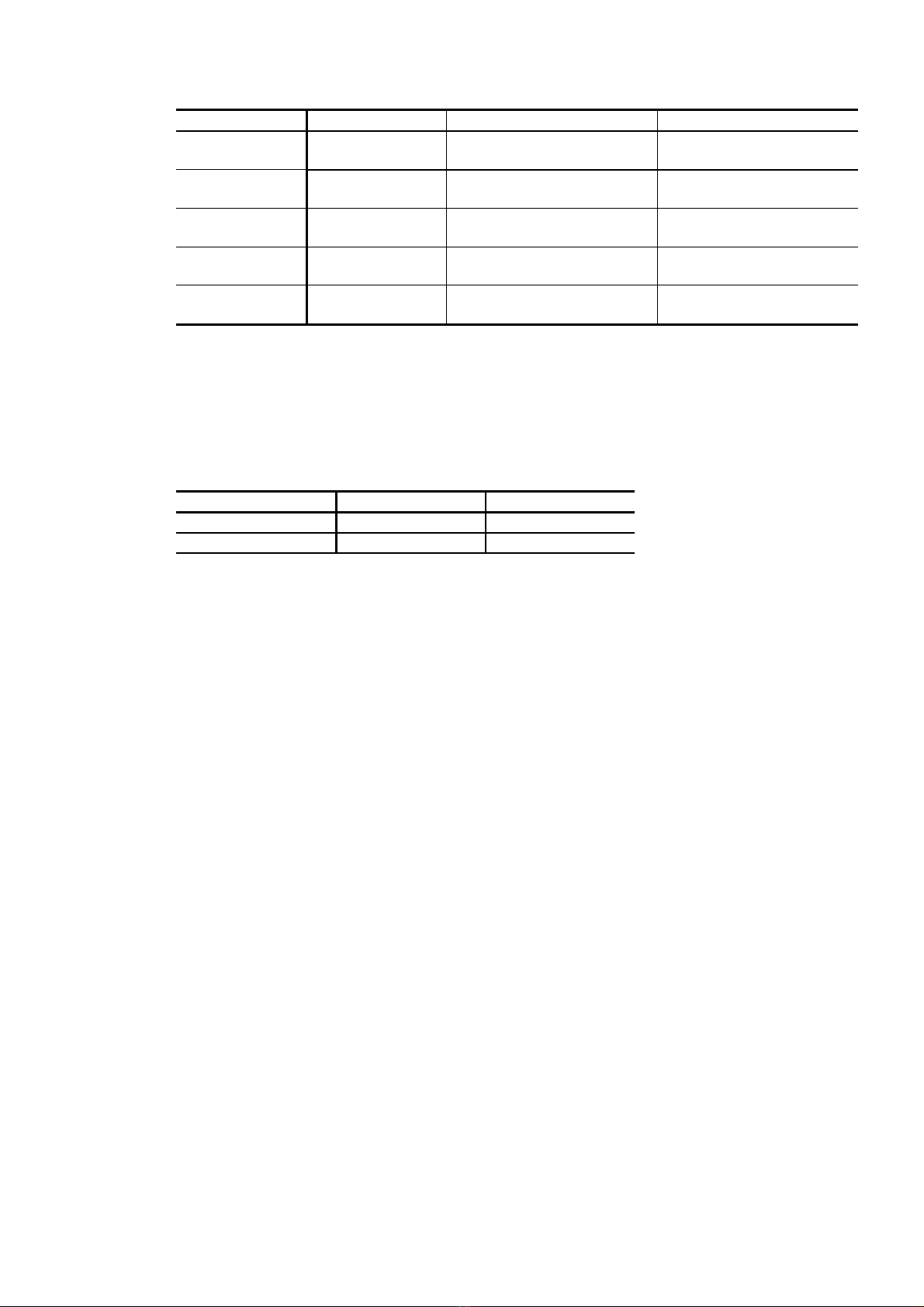

à Standard Megatorque Motors (RS, AS, BS, JS, SS and YSB Series)

They are not made to dustproof or waterproof specification. (Equivalent to IP20, IP30 or IP40)

You may not expose them to humid or oily environment.

à Simple waterproof Motor (RW Series)

Some part of the Motor is not completely waterproofed. Confirm what part is not waterproofed

with the specification document, and then take appropriate measures to the part against water

and dust if necessary. For a long time use of the Motor, we recommend making sure of its aging

trend of the Motor with the periodical insulation test approximately once in every half year.

You cannot use this type of Motors unless you take the measures against the environment with

water or oil.

à Waterproof Motor (RZ series: IP65 equivalent)

Use this type of Motor when continually splash water or oil on it. Provide air purge when you

use the Motor in IP66 or equivalent specification. Be sure to supply a dry air. The user shall

take the measures against dust. For a long term use, check the Motor for its aging by insulation

test (approximately once in every half year).

2Use condition

l The allowable moment load and axial load differ with Motor size. Reconfirm that the using conditions are

in the specified limits of the Motor.

l An excessive offset load or heavy load will cause permanent deflection of the rotor and the bearing

abnormality. Be sure not to give excessive impact to the Motor that is caused by external interference in

transit or at installation.

l The flatness of the Motor mounting surface shall be 0.02 mm or less.

3About Motors equipped with brake

l The brake is power off activated type electromagnetic brake.

l The user shall provide 24 VDC power source. You cannot use power source unit for YS Megatorque

Motor (M-FZ063-1 90VDC).

l Be sure to keep the friction plate of brake free from iron powder or oil.

l The brake may not function if iron made member exists near the brake. Please provide 15 mm or more

clearance between the brake and other members.

4Periodical check

l Puncture of the Motor and shorting or breakage of cable may occur depending on using condition and

environment. If the Motor is left in such conditions, it cannot exhibit its capability 100 % and will lead to

a problem of the Driver Unit. We recommend conducting the periodical check in order to detect the

problem.