8

3.4 - BATTERY REPLACEMENT

Applies to both Control Systems - (Must only be done when the fire is Cool)

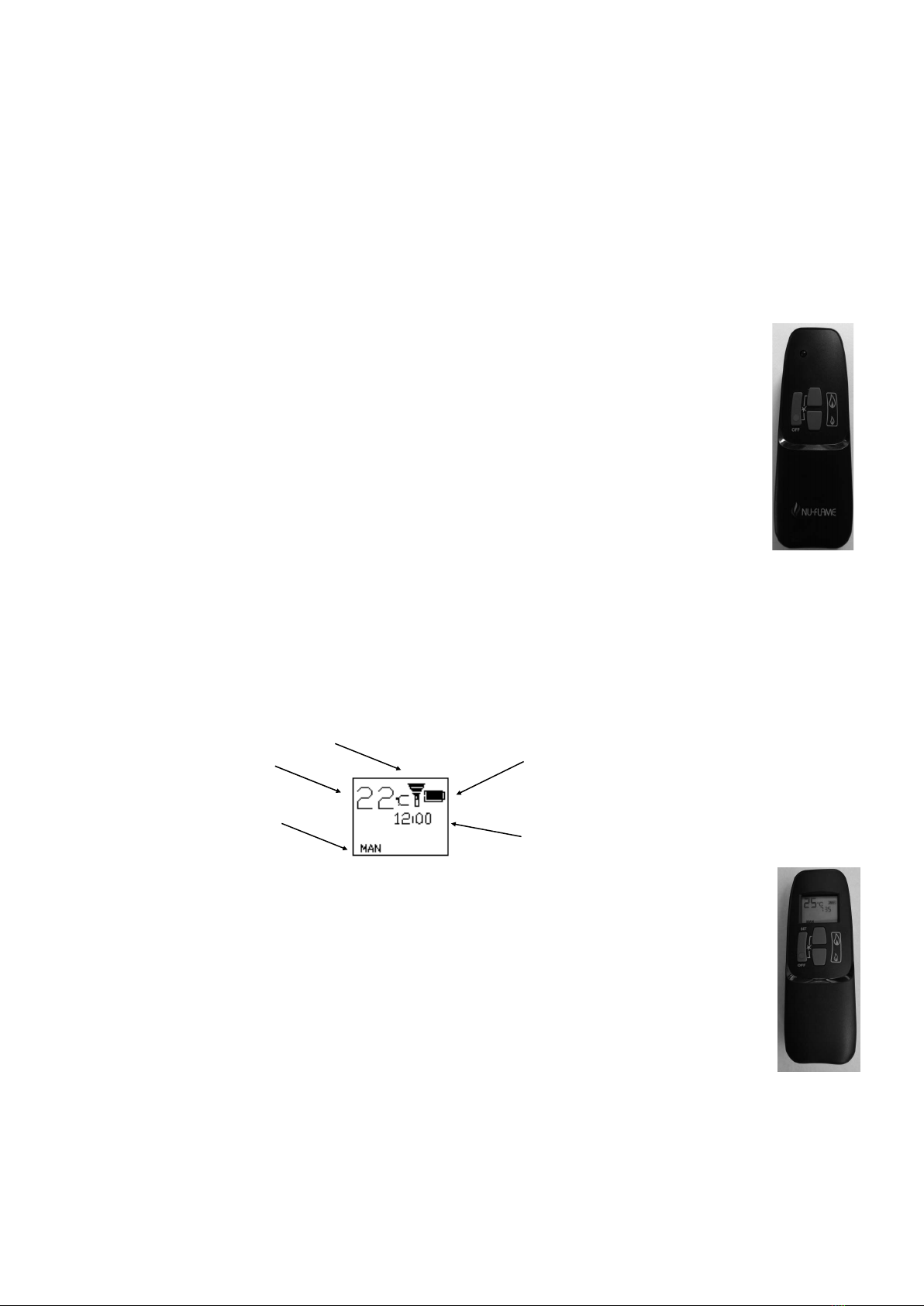

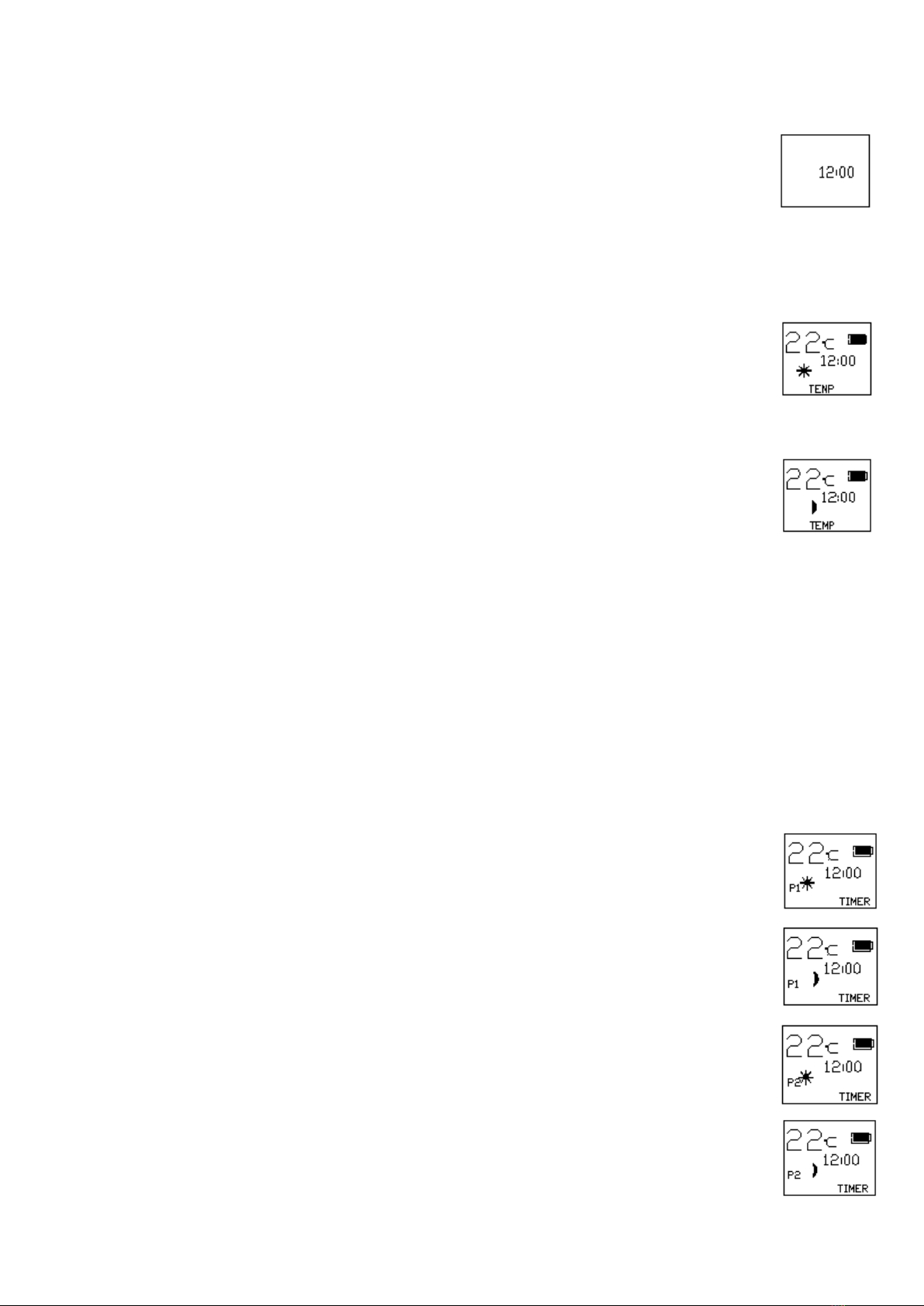

a. A feature of the Thermostatic Thermatronic Handset is it as a Battery Charge Indicator shown in the screen on the

Handset which will determine when both the Handset and Receiver Batteries need changing, however also see ‘b’.

b. For Both Control systems, Battery replacement is recommended at the beginning of each heating season, or when an acoustic error

message sounds during ignition.

c. Error Message – Long signals (0.8 second tone – 0.2 second break) during ignition – probable cause - batteries in electronic

receiver box are nearly discharged.

d. Error Message – 5 second continuous tone – probable cause – cable disconnected or on/off switch on valve is in off position.

e. Batteries - Electronic Receiver Box - 4 x AA good quality alkaline - Handset - 1 x PP3 good quality alkaline.

f. To change the Handset battery slide open the plastic panel on the back of the Handset.

g. To change the Receiver Batteries open the outer door by pulling pull at the left side to release it from the magnetic catches.

Locate the electronic receiver box, underneath the fire on the left hand side. Slide open the plastic cover to gain access to the battery

compartment. You can detach the Receiver by pulling it off its Velcro Pad to make access easier but remember to put it back in the

same position.

Note: Only Change The Batteries When The Fire Is Cold

! WARNING! THE THERMOSTATIC THERMOTRONIC CONTROL SYSTEM PROVIDES THE MEANS FOR UNATTENDED

OPERATION OF THE FIRE IF THE PROGRAMS OR THERMOSTATE SETTINGS ARE USED THIS COULD POSE A DANGER IF

COMBUSTIBLE MATERIALS ARE TOO CLOSE TO THE FIRE OR IF YOUNG CHILDREN, THE ELDERLY OR INFIRM OR PETS

ARE LEFT IN ATTENDANCE.

3.5 - RESETTING THE MERTIK MAXITROL LOGIC CIRCUITS IF THE HANDSET DOES NOT WORK - APPLIES TO

BOTH CONTROL SYSTEMS

Must only be done when the fire is Cool

Basic Reset - It sometimes happens that (such as when the handset buttons are pressed out of sequence) the fire stops

working because the logic circuits get confused and need to be reset.

To do this, simply remove the 4 x AA batteries from the Receiver Box (see section 2.4f above), wait for 1 minute and then refit the

batteries. Wait for another minute and then point the handset at the fire and press the red/off button. Wait for another minute and then start

the fire as normal. If the fire does not start repeat the resetting procedure. If the fire still does not work a Full Reset can be tried.

Full Reset - If you obtain a new handset the control system will need to learn the handset’s unique code via a Full Reset. Also, if the fire is

not working and the Basic Reset has not worked a Full Reset can be carried out:

Open the outer door by pulling at the left side to release it from the magnetic catches and open the outer door, locate the electronic Receiv-

er Box.

Locate the Reset Hole on the side of the Receiver and using a pen press and hold in the Reset button until you hear two beeps.

The first beep is short and the second beep is long. After the second beep release the Reset Button.

Now on the Handset, within the next 20 seconds press and hold the Small Flame Button until you hear two additional short beeps

confirming the code is set in the Receiver.

If you hear one long beep the Code as not been set so repeat the procedure.

If after carrying out the above procedure the situation is not corrected it will be necessary to contact your Installer.

Note: For the Installation/Service Engineer - Resetting of the Handset & Control System is also covered in Section 19.1 page 30.

4.0 - CLEANING THE FIRE

a. Allow to cool before cleaning.

b. The outside of the glass can be cleaned as follows:

Clean glass using (preferably distilled) water and a soft cloth ensuring the glass is dried thoroughly afterwards, again using a soft cloth.

If stubborn marks persist use a purpose produced Ceramic hob cleaner to clean the area again using a soft cloth.

Under no circumstances must an abrasive cleaner be used as this will scratch the glass.

c. It is quite normal for soot to build-up on the inside of the glass panel over time.

The inside of the Glass Door can be cleaned as follows:

Open the outer door, by pulling on the centre of the left hand side.

Using the Pozidriv screwdriver provided unscrew the 2 screws to the Left Side of the door.

Follow instructions in section b. above.

d. The logs or driftwood must not be cleaned or moved.

e. The outer surfaces of the fire can be cleaned with a damp cloth, do not use abrasive cleaners.

! IMPORTANT NOTE ! Under no circumstances must the fire be operated without the glass door being fully closed and secure.

5.0 - SERVICING

a. The fire should be Serviced Annually in accordance with the Gas Safety & Uses Regulations.

b. This fire contains no User Serviceable Parts apart from the batteries.

c. Servicing must be carried out by a Registered Installer.

d. For Servicing or Spare Parts contact your Installer quoting the Fire Name, Model and Serial Number, which can be found on the Data

Badge. To find the Data Badge/Plate; with the fire cool open the outer door, the Data Badge/Plate can be found at the base next to the

Control.

e. In the event that the fire shuts down due to any reason, attempt to restart it. If there is a continuing problem, call in a properly

qualified specialist engineer.

f. Under No Circumstances must this fire be used if the Glass Panel is broken damaged or cracked or if the Door Seal is

damaged