NuAire ES-MEV Assembly instructions

Other NuAire Fan manuals

NuAire

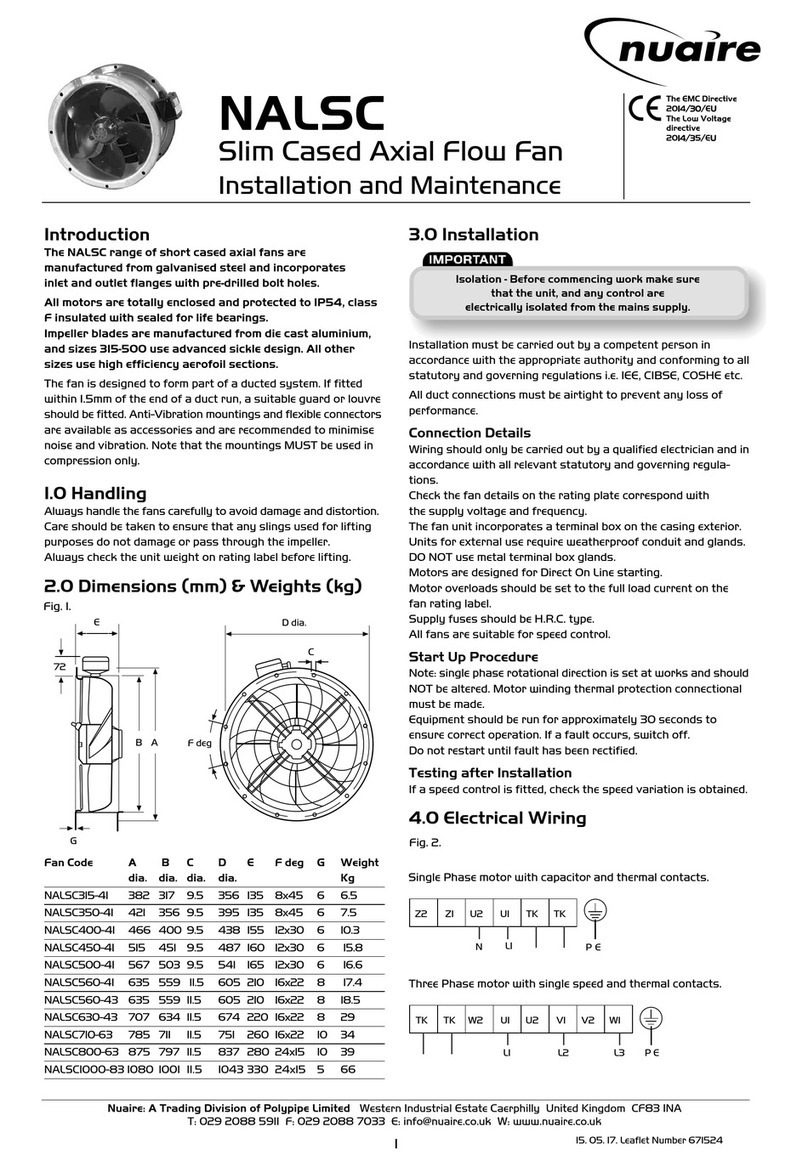

NuAire NALSC Instruction Manual

NuAire

NuAire MRXBOX-ECO2 User manual

NuAire

NuAire OPUS 30 Instruction Manual

NuAire

NuAire MRXBOXAB-ECO2-SW User manual

NuAire

NuAire MEVDC User manual

NuAire

NuAire MRXBOXAB-ECO2B User manual

NuAire

NuAire AXUS SVT2 Instruction Manual

NuAire

NuAire iSense User manual

NuAire

NuAire SLIMAIRE/NA Series Instruction Manual

NuAire

NuAire MRXBOXAB-ECO3-1ZSW User manual

NuAire

NuAire MRXBOX95ABWM2QA12338 Instruction Manual

NuAire

NuAire SQF User manual

NuAire

NuAire Ecosmart ESTCP Instruction Manual

NuAire

NuAire NOXMASTER Series Instruction Manual

NuAire

NuAire MVHR-LP-AC Instruction Manual

NuAire

NuAire MRXBOXAB-ECO2B-SW User manual

NuAire

NuAire MRXBOXAB-ECO4 User manual

NuAire

NuAire SUNWARM TILE 1 Installation guide

NuAire

NuAire MRXBOX95B-LPIH Instruction Manual

NuAire

NuAire OPUS100 User manual

Popular Fan manuals by other brands

ELTA FANS

ELTA FANS H03VV-F installation guide

Hunter

Hunter 20714 Owner's guide and installation manual

Emerson

Emerson CARRERA VERANDA CF542ORB00 owner's manual

Hunter

Hunter Caraway Owner's guide and installation manual

Panasonic

Panasonic FV-15NLFS1 Service manual

Kompernass

Kompernass KH 1150 operating instructions