3

16. 04. 21. Document Number 671965

Nuaire | Western Industrial Estate | Caerphilly | CF83 1NA | nuaire.co.uk

HIAQMInstallation Manual

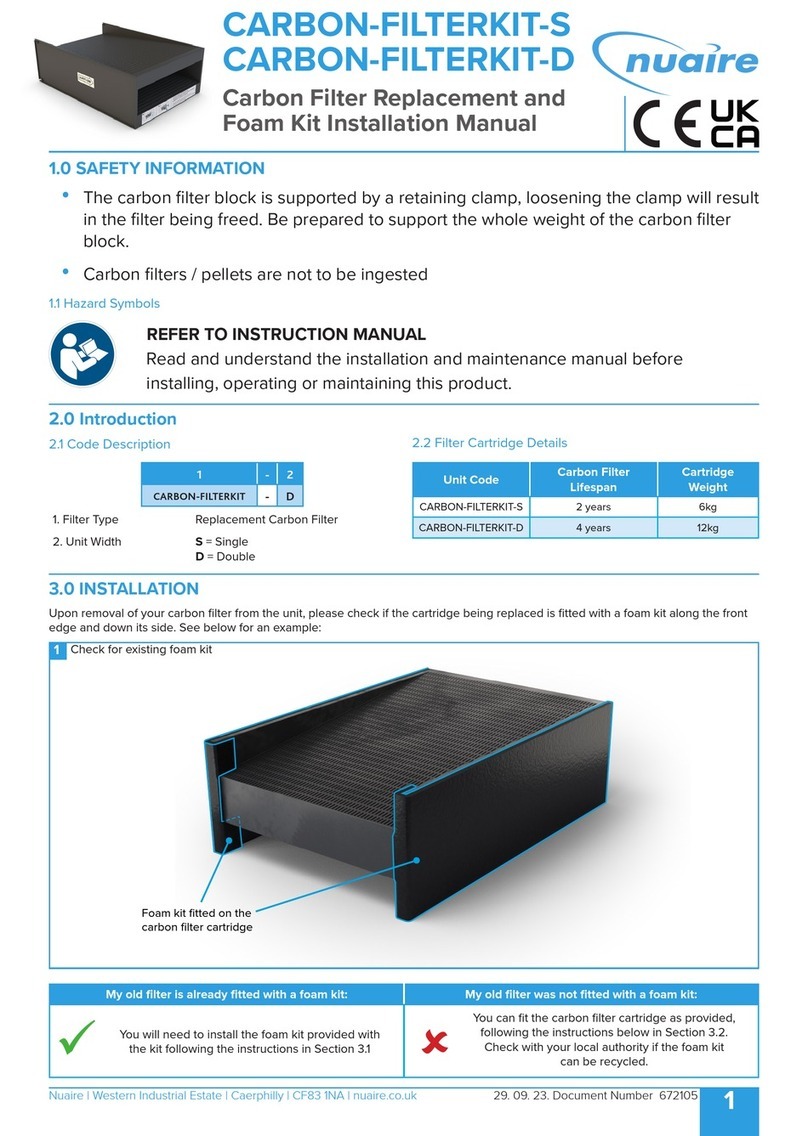

2.3 Delivery of Equipment

2.3.1 Receipt of Equipment

All equipment is inspected prior to despatch and leaves the factory in

good condition. Upon receipt of the equipment an inspection should be

made and any damage indicated on the delivery note.

Particulars of damage and/or incomplete delivery should be endorsed

by the driver delivering the goods before offloading by the purchaser.

No responsibility will be accepted for damage sustained during the

offloading from the vehicle or on the site thereafter. All claims for

damage and/or incomplete delivery must be reported to Nuaire within

two days of receipt of the equipment following guidance in our terms &

conditions of sale.

2.3.2 Offloading and Handling

The weight of the unit modules and palletised items is displayed on

the unit rating plate or on the packaging. Some of the modules have an

uneven weight distribution, and this will be indicated by labelling where

appropriate. Ensure that lifting and handling equipment is adequately

rated. Offloading and positioning of the equipment is the responsibility

of the purchaser.

Spreaders should be used when lifting with slings to avoid damage

to the casings. Care must be taken to ensure that slings are correctly

positioned to avoid crushing and twisting of the unit castings.

4 Unit Lifting

Palletised.

Slings via spreaders fitted to unit with base frame.

3.0 MECHANICAL INSTALLATION

Installation of the IAQ modules, including all external services and

controls should be in accordance with the appropriate authority and

MUST conform to all governing regulations e.g. CDM, CIBSE, IEE, and in

strict accordance with the applicable Building Regulations. These units

may only be mounted horizontally.

The correct installation position for the units shall be decided with due

regard to access and maintenance requirements, and the objective of

minimising the system ductwork resistance.

The units are heavy, and should be mounted using the fixing brackets

supplied or other suitable methods of support. The supporting structure

must be assessed for structural suitability.

The recommended installation method is to use standard Unistrut

channel secured to the slab / steelwork above the unit.

Four suitable drop rods should be secured to the Unistrut channel and

extended to be fixed to the unit’s four mounting brackets (two each

side of the unit), or to other horizontal supports by others where wider

load distribution is required.

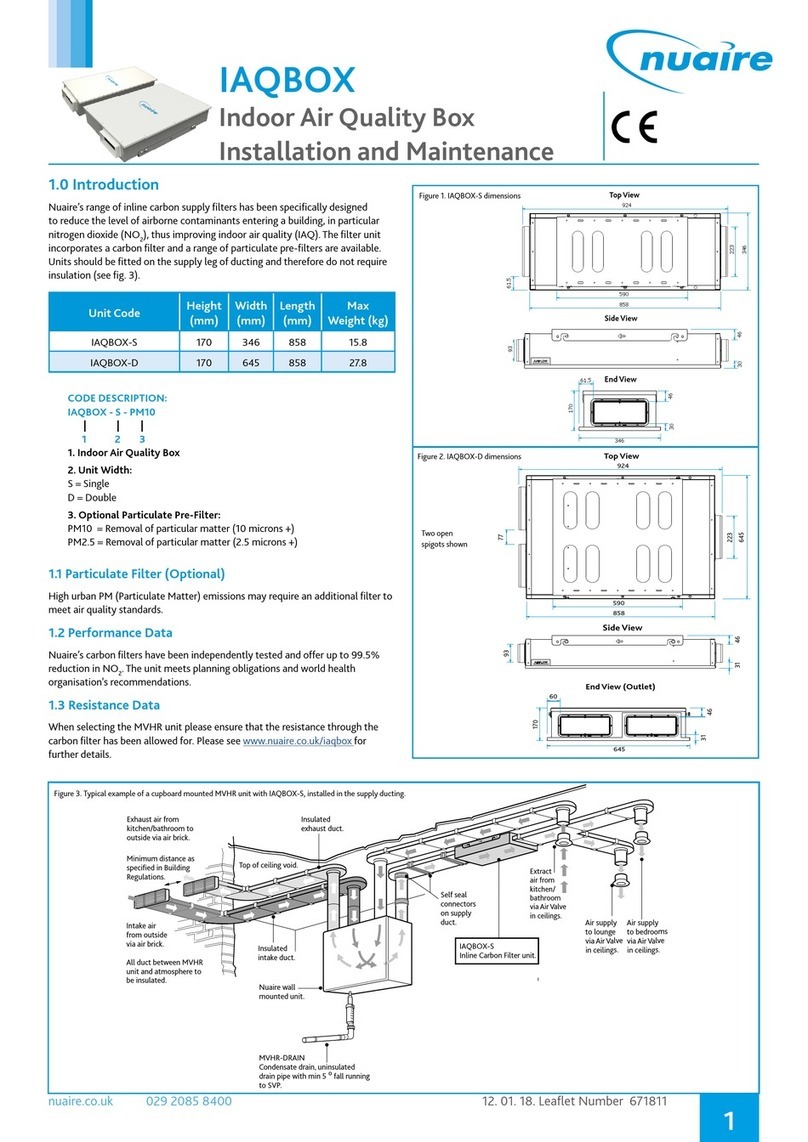

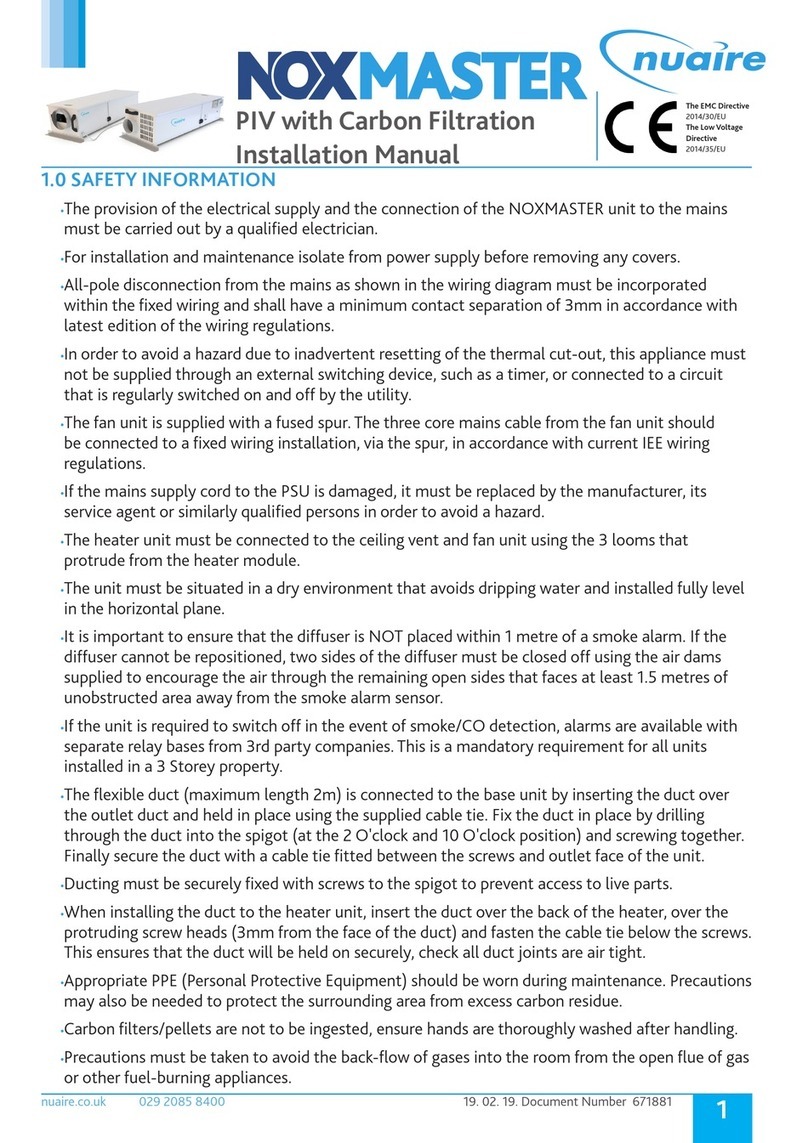

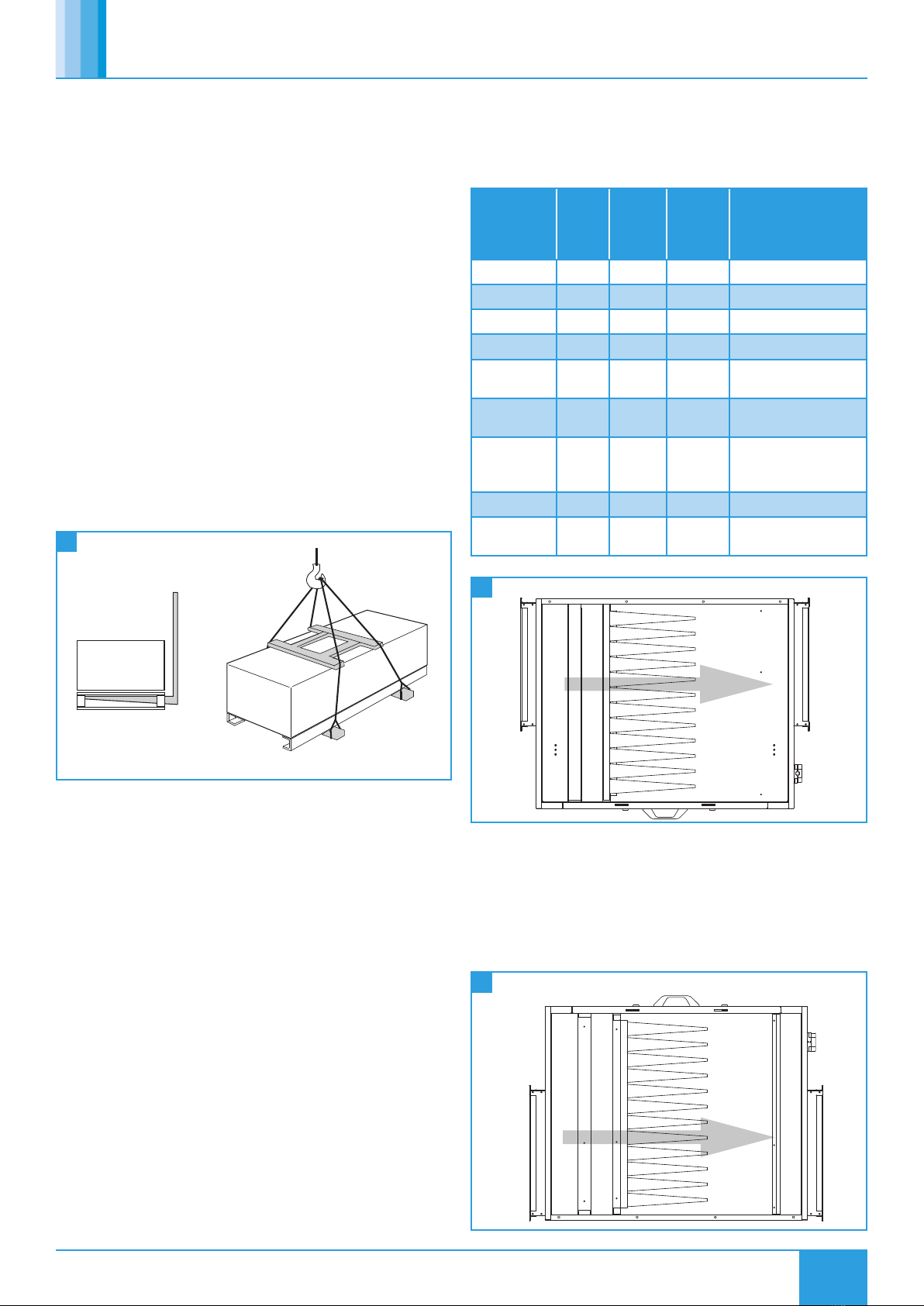

3.1 IAQM Layout Modifications

Depending on the installation requirements of the IAQM unit (e.g.

location, orientation, model variant, etc.), onsite modifications of the

module may be needed. Refer to the table provided for modification

requirements.

Fan Unit

Attachment

Method

Access

Type

HIAQM

Roof

XBC

Unit

Handing

Required IAQM

Layout Modifications

Ducted Side No N/A None.

Ducted Side Yes N/A None.

Ducted Bottom No N/A None.

Close Coupled Side No Left Attach XBC Flange.

Close Coupled Side No Right Attach XBC Flange,

Roll IAQM Unit.

Close Coupled Side Yes Left Attach XBC Flange,

Relocate IAQM Roof,

Close Coupled Side Yes Right

Attach XBC Flange,

Roll IAQM Unit,

Relocate IAQM Roof.

Close Coupled Bottom No Left Attach XBC Flange.

Close Coupled Bottom No Right Switch Spigot Plates,

Attach XBC Flange.

Side Access IAQM Modified For Use With Left Handed XBC’s

AIRFLOW

5 Standard IAQM Layout

3.1.1 Switching Spigot Plates

If bottom access IAQM unit is to be close coupled to a right hand

configuration XBC unit, the IAQM unit inlet and outlet spigot plates

must be switched to ensure XBC ducting paths are clear. Detach both

IAQM spigot plates by removing the bolts securing the plate to the

IAQM unit. Exchange the inlet and outlet spigot plates and reattach to

the IAQM using the same bolts and fixing points.

Side Access IAQM Modified For Use With Left Handed XBC’s Side Access IAQM For Use With Right Handed XBC’s

AIRFLOW

6 Modified (Spigot Plates Switched) IAQM Layout