Ceiling Vent

Two Air Dams (supplied) can t on any of the diuser sides to guide

airow away from a smoke detector and/or obstructions as required.

Diuser Cap

Airow

Airow

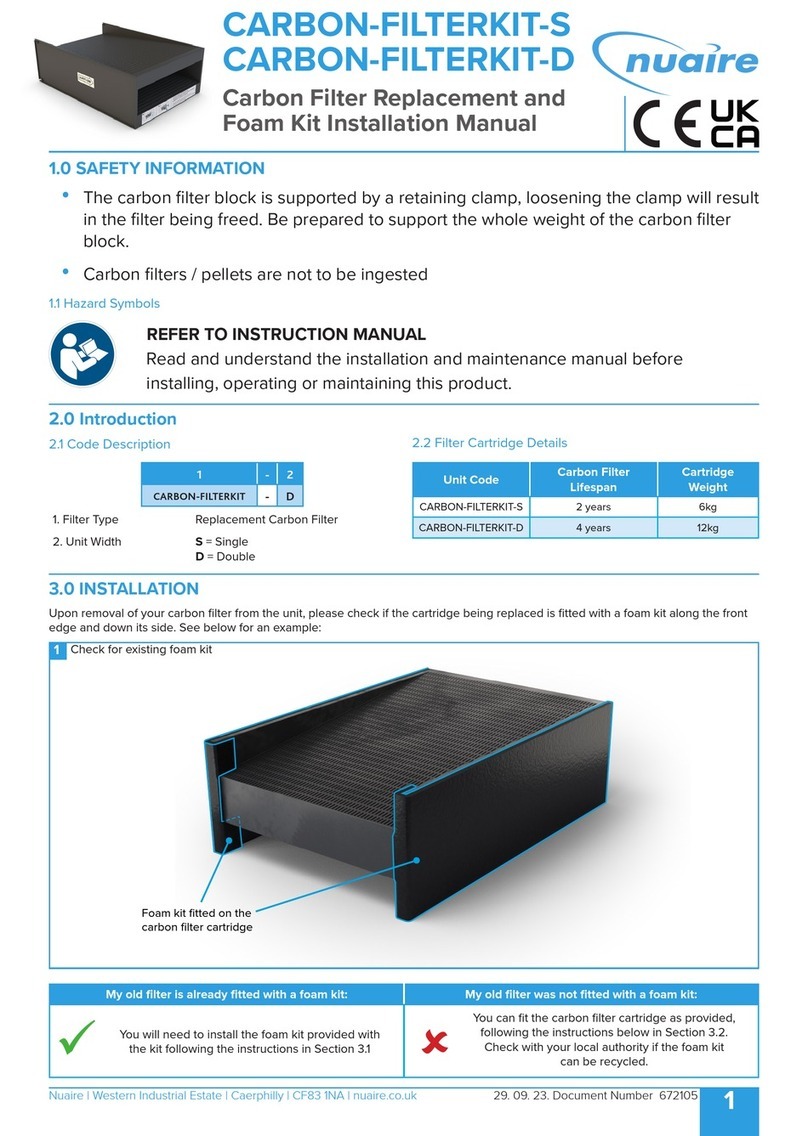

4.2 Diffuser Installation

4.2.1 Positioning the Diffuser

The diffuser has a unique air throw pattern and it is essential that it is

located correctly in the central hallway in single storey properties or in

the ceiling of the top floor landing on two or more storey dwellings.

The diffuser discharges air evenly in all directions along the underside of

the ceiling.

Note: SMOKE ALARMS -It is also important to ensure that the

diffuser is NOT placed within 1 metre of a smoke alarm.

If the diffuser cannot be repositioned, two sides of the diffuser must

be closed off using the air dams supplied to encourage the air through

the remaining open sides that faces at least 1.5 metres of unobstructed

area away from the smoke alarm sensor.

4.2.2 Fitting the Air Dams (if Required)

Air dams should be fitted where needed in order to alter the direction

of airflow. Two air dams are supplied and will fit on any of the diffuser

sides to guide airflow away from a smoke detector and/or obstructions.

4.2.3 Fitting the Ceiling Diffuser

To install the diffuser, use the tear-out template from the lid of the unit

packaging and trace the shape onto the ceiling between two convenient

The heater unit must be connected to the ceiling vent and fan unit

using the 3 looms that protrude from the heater module. Connect

the ceiling vent control loom to the circuit board on the ceiling vent

and insert the heater module into the ceiling vent. Connect the

interconnecting loom into the control output and the mains power

loom into the heater output (Figure 4). The flexible duct (maximum

length 2m) is connected to the base unit by inserting the duct over the

outlet duct and held in place using the supplied cable tie.

Finally when installing the duct to the heater unit, insert the duct over

the back of the heater, over the protruding screw heads (3mm from the

face of the duct) and fasten the cable tie below the screws. This ensures

that the duct will be held on securely, check all duct joints are air tight.

FURTHER MEASURES MAY BE REQUIRED.

4.3 NOXMASTER Installation

4.3.1 Connecting Sections

The unit is delivered in two sections, pod A (Carbon filter) and pod B

(blower) which require connecting, refer to the layout drawing (Figure

1).

•Remove the nut and bolt from the black connectors on either side

of the unit and store safely to one side.

•Position the pods 1 – 1.5M away from the desired location of

the ceiling vent. Align the two pods with both spigots facing

out, leaving a space between the pods to make the electrical

connection (Figure 5).

•Release the free end of the fly lead from pod B and align the flats

on the male connectors with the flats on the fixed connector in

pod A. Push the connectors together until the outer clips have fully

engaged and the connection is secure.

•Pull the pods together and re-insert the nut and bolt back into

the black connectors. Tighten the connectors evenly, when fully

tightened ensure the foam gasket has been evenly compressed.

4.3.2 Fitting the NOXMASTER

Connect the two ‘L’ shape fixing brackets to the short sides of the unit

with the M5 screws (provided), then lower the unit with the “L” shape

fixing brackets attached, onto the joists. Mark 4 holes through the

brackets so that the holes will be centrally positioned over a joist.

Locate anti-vibration mounts (supplied) above and below each bracket

fixing joint hole and, using the fixings provided, fix the unit to the joists.

Note: Do not overtighten the fixings.

Connect the flexible duct (maximum length 2m) to the blower unit

by placing the duct over the spigot. Secure the duct in place by drilling

through the duct and spigot (at the 2 O'clock and 10 O'clock position)

and securing with screws (provided). Finally secure the duct to the

heater/ceiling diffuser. Secure with a with a cable tie fitted between the

screws and outlet face of the unit. To connect to the ceiling vent place

the duct over the vent and secure with cable tie. Ensure all duct joints

are airtight.

Please note: The flexible ducting should NOT be installed

in a compressive state, as this will negatively impact on the

performance of the unit.

Figure 3. CeilingDiffuser

joists. The shape is elliptical to allow space for the PCB of the controls

and this should be positioned for ease of access (i.e. NOT facing over

a stairwell). Once the shape has been cut out, position the ceiling vent

and secure it in place using the 4 screws and plugs provided. After

fitting, the fan unit must be connected to the diffuser using the loom

provided. The connectors are located on the rear of the ceiling vent and

the side of the POD B below the controls.

Finally, attach the diffuser cap to the frame using the four built-in, press

on clips provided.

4.2.4 Fitting the Heater (if Applicable)

IMPORTANT

In the event of an ESD to the back of the control PCB on the

diffuser the heater may switch off. The heater can be switched

back on by pressing the button in the normal way for enabling

the heater. Care therefore should be taken not to touch the

back of the PCB during installation/commissioning.

Speed Setting Minimum distance of diffuser from wall

1 100mm

2 155mm

3 400mm

4 625mm

5 850mm

6 1000mm

IMPORTANT

The unit must be situated in a dry environment that avoids

dripping water and installed fully level in the horizontal plane.