10

EN

TECHNICAL OWNER MANUAL

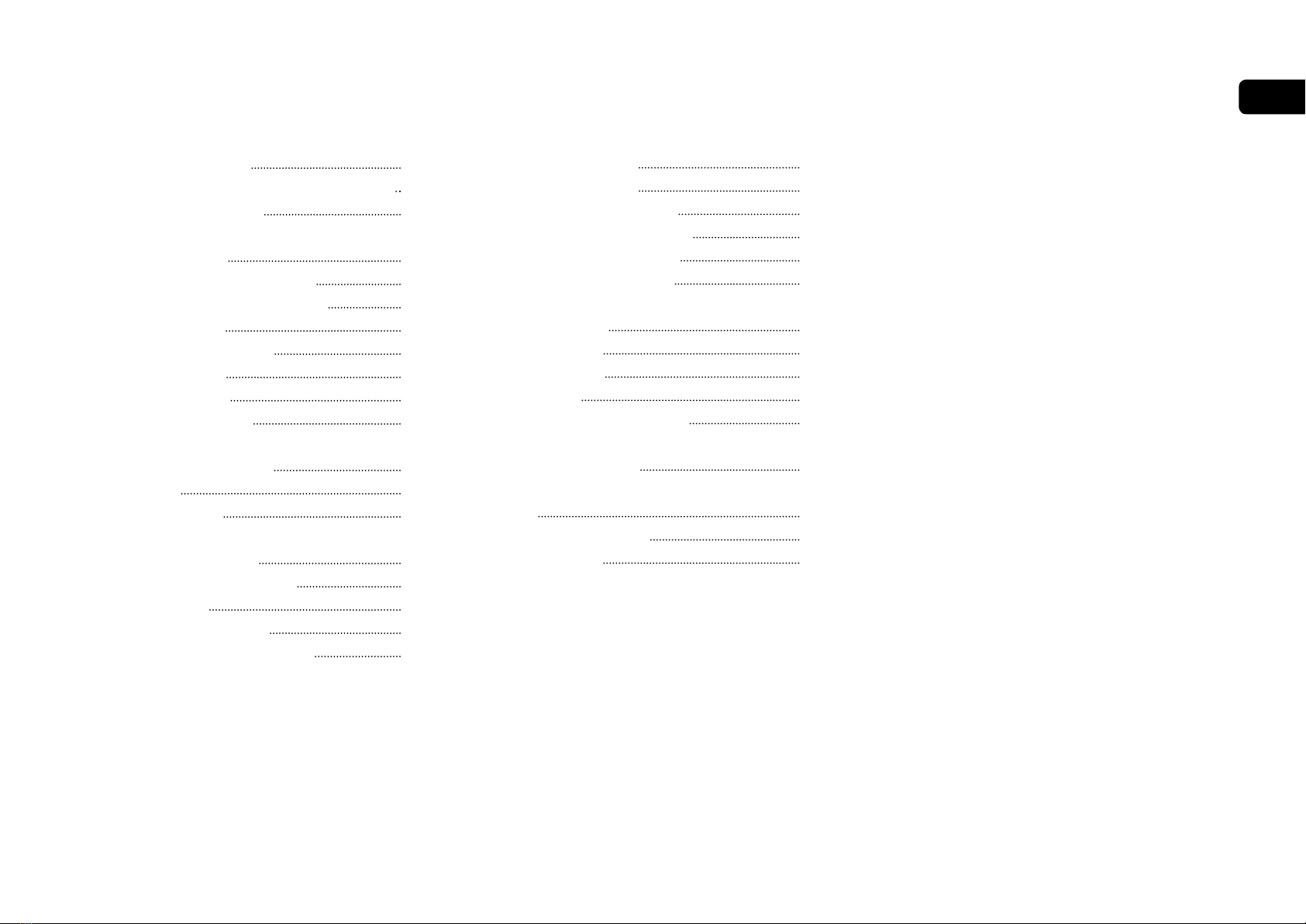

NFINITY ASSEMBLY OF COMPONENTS

A

B

C

D

• See section 5.1 (for chainline and beltline

specifications)

• The NuVinci Optimized CVPs are

compatible with 16 to 28 tooth sprockets.

See section 5.1 for sprocket ratio

requirements and approved gearing

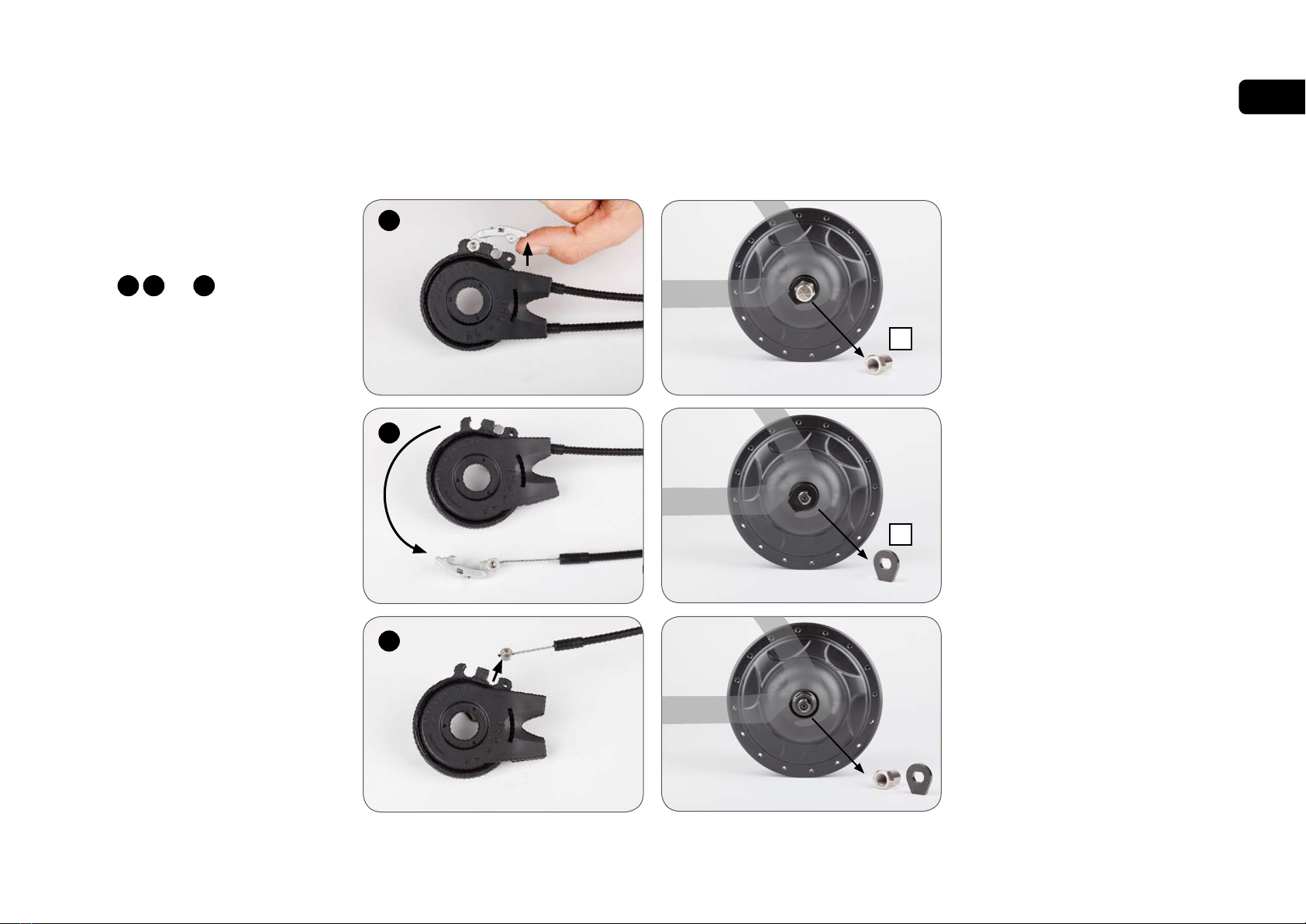

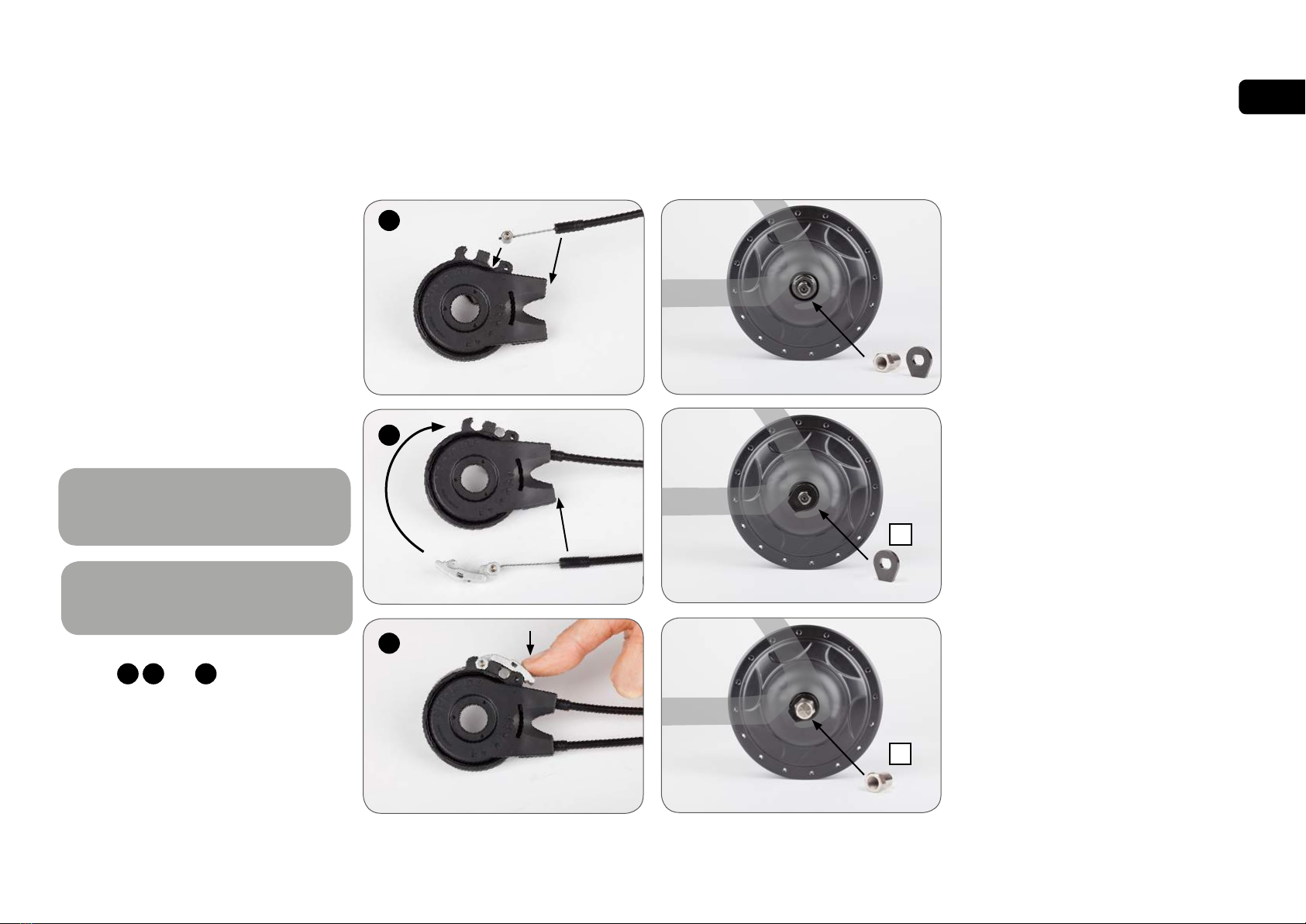

3. If a Nfinity Hub Interface is not installed

immediately following the sprocket, replace

the anti-shift retainer (A)

3.2 Installing the Sprocket

1. Remove the anti-shift retainer (A) by pulling

firmly away from the NuVinci CVP

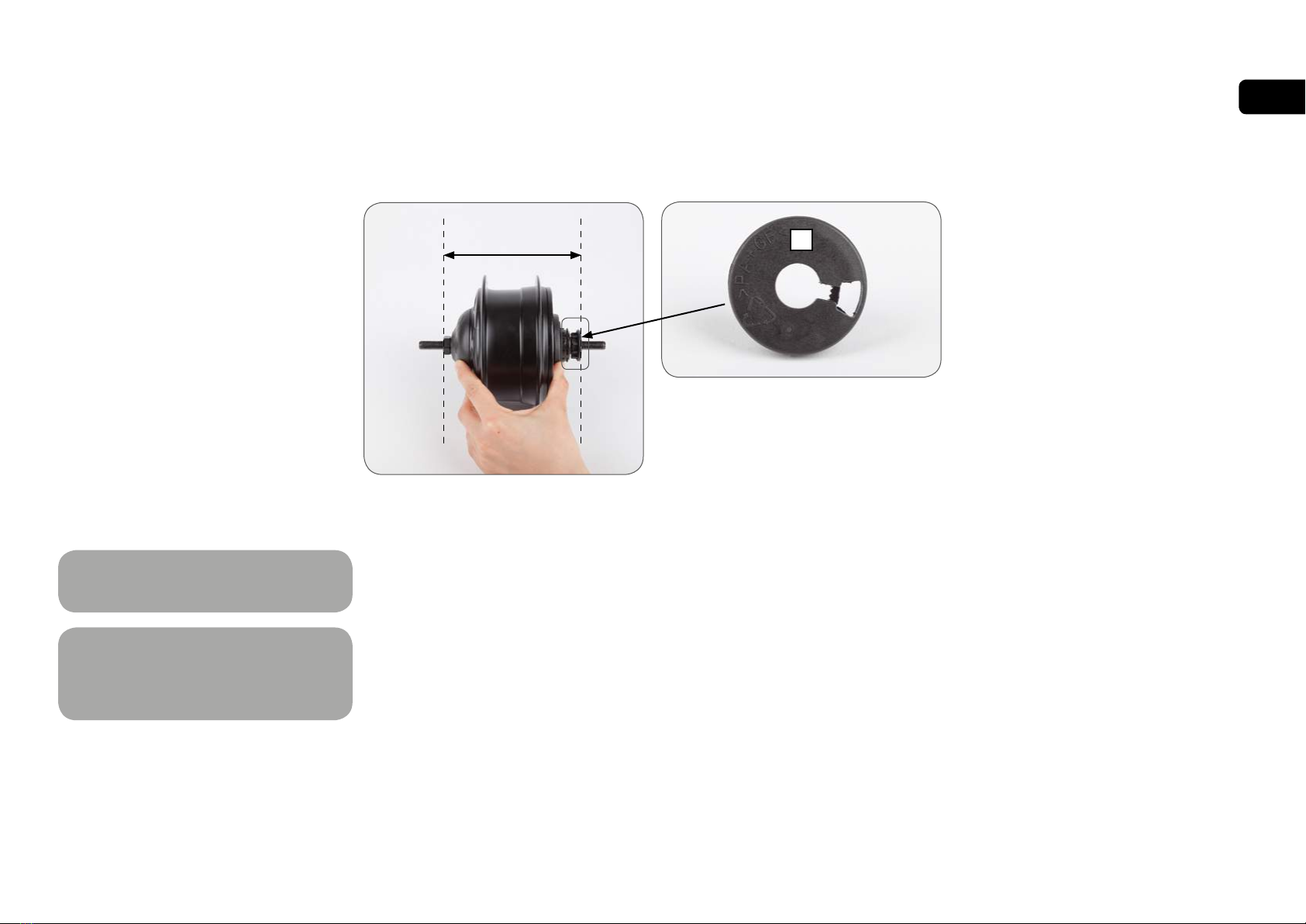

2. Install a standard 9-spline 3/32 inch

(2.3mm) sprocket (B) with the flat side

facing the CVP, followed by the supplied

sprocket spacer (C, if required), and secure

with the sprocket snap ring (D).

• The sprocket spacer is intended for

sprockets that are 3/32 inch (2.3mm) thick

at the inner diameter. If the inner diameter

is 0.17-0.18 inch (4.3-4.5mm) thick, the

spacer should not be used.

Use of incompatible chains can

result in interference with the Nfinity

Hub Interface and damage to CVP

components and may result in a dangerous

condition for the rider.

NuVinci Optimized CVPs are

incompatible with 1/8 inch

(3.18mm) single-speed chains and

sprockets that are flat on at least one side.

Use 3/32 inch (2.3mm) chains and sprockets

only.

If the sprocket is asymmetric, incorrect

installation can result in interference

with the Nfinity Hub Interface and

damage to CVP components and may result

in a dangerous condition for the rider.

!

!

!

Nfinity 330 systems are compatible

with mid-motor eBike systems rated

at 250W or less. See section 5.2 for

approved gearing tables.

Nfinity 380 systems are compatible with mid-

motor eBike systems rated at 350W or less.

See section 5.2 for approved gearing tables.

!