nVent.com | 5

No user maintenance is required! There are no user

adjustments or calibrations that can be performed in the field.

Each TTA-SIM is tested and calibrated at the factory. An

operating TTA-SIM runs a continuous self check routine and

reports any discrepancies to the TTDM-128 or host computer.

If the TTA-SIM or the network wiring fails in such a way that

the TTA-SIM cannot communicate with the host, then the host

reports the failure as a communications failure.

Status Indicators

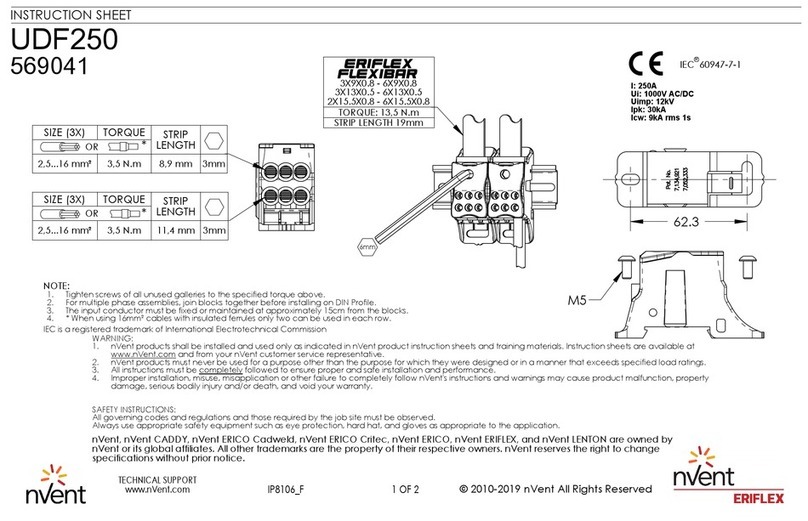

There are 5 LED’s on the TTA-SIM-1A circuit board to indicate:

power, communications (inbound and outbound), sensor status

(leak detected and trouble). See Figure 9.

The green Power LED will be ON and will blink once every

5 seconds when the TTA-SIM is powered and fuctioning

correctly. Table 1 lists various sensor status conditions and

possible corrective actions. Table 2 lists communication status

conditions (applicable when the TTA-SIM is used in a network

system).

Figure 9. TTA-SIM-1A LED positions (all LEDs are located on the

TTSIM unit)

Table 1. TTA-SIM-1A LED operational status indications

Table 2. TTA-SIM communication status indications

(onlyactive if connected to a network)

Leak Service Indication TX RX Indication

FLASH Leak detected. Check sensor for leak or spill. FLASH FLASH Unit is communicating normally with TTDM-128

or host.

ON Leak alarm has been reset by operator but the

leak condition still exists

OFF FLASH Unit is receiving communication from TTDM-128

or host, but is not responding.

FLASH The sensor needs servicing. Check sensor

and leadwires/jumpers for continuity or

contamination.

OFF ON RS-485 communication wires are reversed

OFF OFF

Unit is not communicating with TTDM-128 or host.

TX (Yellow)

RX (Yellow)

Power (Green)

Service (Yellow)

Leak (Red)

Operating Instructions: TTA-SIM-1A

No user maintenance is required! There are no user adjustments or

calibrations that can be performed in the field.

Each TTA-SIM is tested and calibrated at the factory. An operating

TTA-SIM runs a continuous self check routine and reports any

discrepancies to the TTDM-128 or host computer. If the TTA-SIM

or the network wiring fails in such a way that the TTA-SIM cannot

communicate with the host, then the host reports the failure as a

communications failure.

Status Indicators

There are 5 LEDs on the TTA-SIM-2 to indicate: power,

communications (RX=inbound and TX=outbound), sensor status

(leak detected and trouble). There is also a Reset pushbutton which

is used to acknowledge or reset alarms or for updating the location

display. See Figure 10 for the location of the LEDs and RESET

pushbutton.

The green Power LED will be ON and will blink once every 5 seconds

when the TTA-SIM-2 is powered and fuctioning correctly. Table3

lists various sensor status conditions and possible corrective

actions. Table 4 lists communication status conditions

(applicable when the TTA-SIM is used in a network system).

Figure 10. TTA-SIM-2 LED positions (all LEDs are located on the TTSIM unit)

TX (Yellow)

RX (Yellow)

Power (Green)

Service (Yellow)

Leak (Red)

Reset pushbutton

Operating Instructions: TTA-SIM-2