10

3. INSTALLATION NOTES

The installation and, if necessary, the maintenance and

The installation must be compatible with local regulations.

Check the maximum circuit length for your circuit breaker in the next table:

Maximum circuit length at 230 VAC and for 20°C start-up temperature

C-characteristic circuit breaker

Multiple units on multiple power points can be used if longer heating

cables are required. We recommend to use Raychem HWAT-SBS panels

to operate 3, 6, 9 or 12 heating circuits.

Fig. 1 HWAT-L HWAT-M HWAT-R

Circuit breaker (Yellow) (Orange) (Red)

C 10A 80 m 50 m 50 m

C 13A 110 m 65 m 65 m

C 16A 140 m 80 m 80 m

C 20A 180 m 100 m 100 m

The HWAT-ECO has a removable top lid. Both top and bottom of the box

have electronic parts and are connected to each other by an Ethernet

connector cable. The unit is delivered with top lid and back part dismantled.

Warning: For over voltage protection (e.g. in case of thunderstorm)

we recommend the use of an external over voltage protection device.

Care and maintenance

Clean the HWAT-ECO with a soft damp cloth only, do not use any

solvents. Do not pour water directly on the device. Do not use a water

hose or a high pressure cleaner.

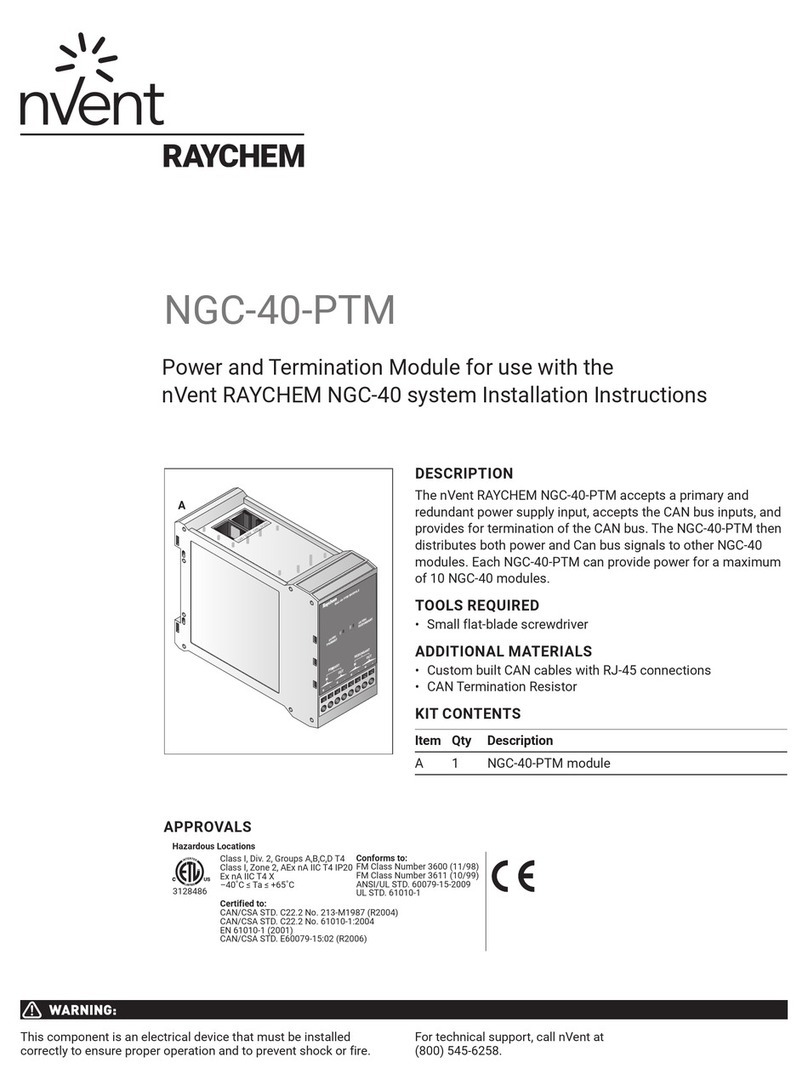

3.1. Description

The HWAT-ECO control unit has been developed for operation with the

self-regulating heating cables: HWAT-R, HWAT-M and HWAT-L. The hot

water temperature maintenance system is a comfort system providing

instant hot water at the tap.

A self-regulating heating cable is positioned on the pipe and

compensates for any temperature loss of the warm water.

The HWAT-ECO control unit combines the following features:

The operating temperature of the heating cable can be limited to a

desired temperature. Combined with the integrated “power off” timer

function, this offers important energy savings.

Energy can be saved upon activation of the “trace boiler” function and

installation of the boiler sensor. The maintain temperature of the

heating cable will automatically be lowered in case the boiler

temperature is reduced, preventing the heating cable from using too

much energy for heating the water in the pipes.

HWAT-ECO unit in a Raychem SBS panel to manage multiple heating

circuits. The HWAT-ECO controller can be delivered in different

prefabricated panels, depending on the quantity of heating circuits

(3, 6, 9).

An alarm terminal makes remote reading of errors possible.

A pipe sensor (to be ordered separately) can be installed as reference

point to track and monitor pipe temperature in a large hot water

distribution network.

The unit can be pre-programmed in power-off mode by external power

bank (to be ordered separately) connected via A-A-USB cable and USB

connection.