Carima DM400A User manual

USER

MANUAL

CARIMA 3D PRINTER

www.carima.com

DUAL

ENGINE Dual 2K

THE

WORLD

FIRST

THE

WORLD

FIRST

400 x 330 x 500mm

The first large build size with

single exposure at single layer

Native 132µm

PIXEL SIZE

(X/Y)

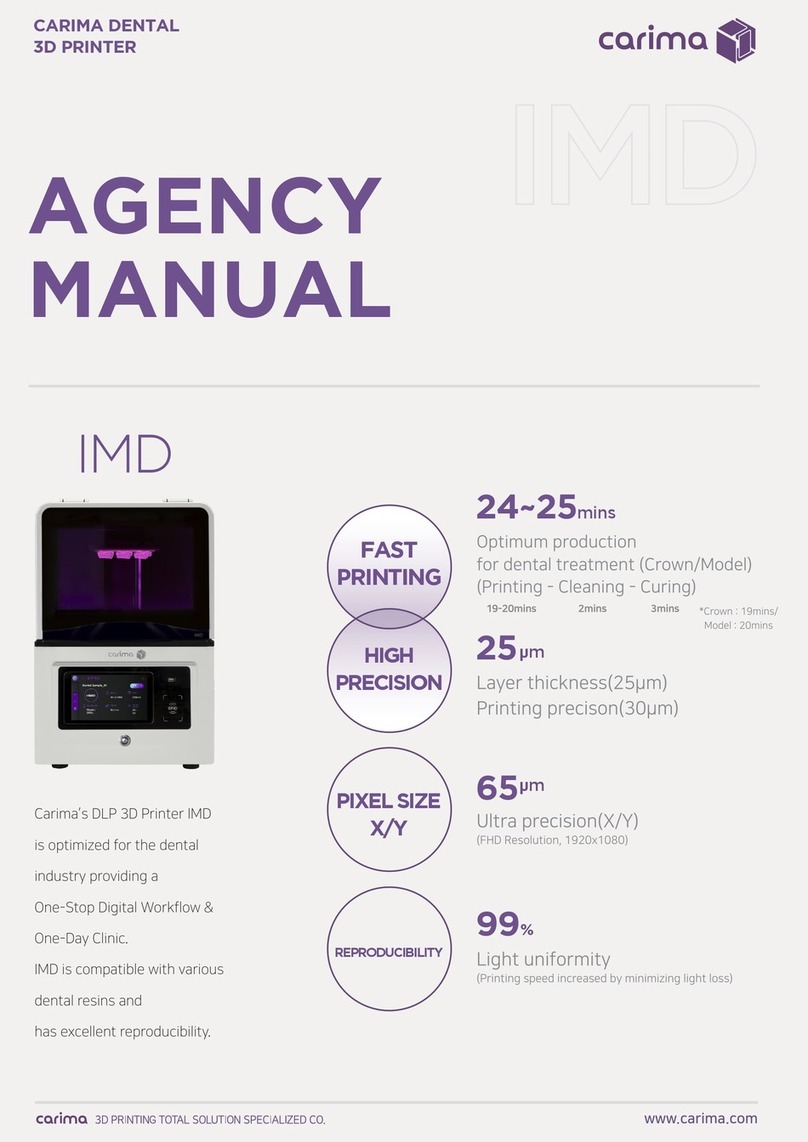

DM400A

Direct final production with industrial tough material.

No limitation with weight and size.

Easy to change vat system.

This manual provides

instructions on how to

use the "DM400A."

Understand how to

use "DM400A"

through the manual

and experience

Carima’s "DM400A"

easily and conveniently.

00

CONTENTS

DM400A USER MANUAL

www.carima.com

Introduction

Specification

Product Overview

Process Overview

Safety Warnings &

01

Contents

01

02

03

Finishing Prints

03

Demounting & 17-18

Post-processing

Preparation and Setup

02

04-05

06-16

Printing Preparation

Using the LCD Panel

Maintenance

04

19-20Maintaining the Printer

& Maintaining Other Accessories

[email protected]82-2-3663-8877

Introduction

01

INTRODUCTION

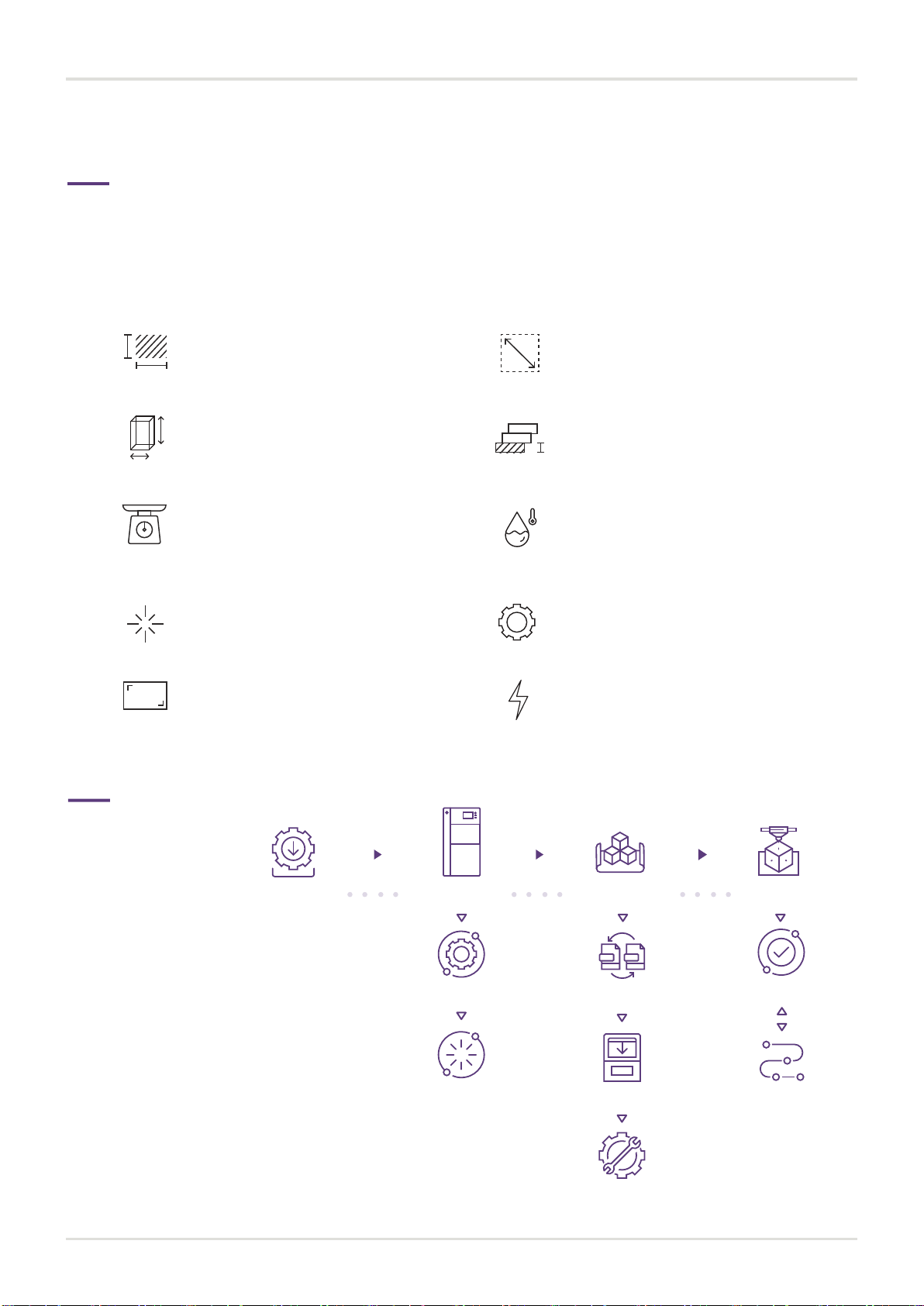

DM400A Specification

The DM400A uses a high-resolution engine to enable precise and perfect output even in a large area.

DM400A USER MANUAL

www.carima.com

132 μm

Precision

50,100, 125, 150 μm

Layer Thickness

405nm UV LED

Light Source

Dual 2K high 2560 x 1600

Resolution

Product Size (mm) [W x D x H]

1010 x 1134 x1933

Weight

1000 kg / 2205 lbs

(Printer 750kg, Resin 220kg)

Embedded touch screen

Control Type

18-26 (℃) / 64-79 (℉)

20% - 50% (humidity)

Using Environment

Power

AC 100-220V 50~60Hz 4A

Printing Size(mm) [W x D x H]

400 x 330 x 500

[email protected]82-2-3663-8877

Process

Overview

Convert File

Load Data

Control Setting

Setup

Load

Install

(CARIMA SLICER)

PreparingSetting Printing

Check

Post-

processing

Product Overview

02

INTRODUCTION

DM400A USER MANUAL

www.carima.com

[email protected]82-2-3663-8877

Internal Structure

03

02

Front

01

Back

Vat

Level Sensor

Actuator

Level Controller

Sweeper

101 cm

193 cm

LED Power Button

USB Port

LCD Touch Screen

Print Room Cover

Emergency Power

Button

Build Plate

Printer Cooler

Key Insert Lock

Power Cable

Connector

Ethernet

Connector

This information is intended to protect your safety and prevent property damage.

Please be aware of the precautions before using, to prevent serious injuries and printer damage.

03

INTRODUCTION

DM400A USER MANUAL

www.carima.com

Safety Warnings

When printing, put the printer in a well-ventilated place because resin may smell.

Do not use volatile objects near the printer as they may cause fire or explosion.

When the printer power is on, please do not force shutdown by pressing the emergency power button

on the front of the printer. Forced shutdown shortens the life of the digital light engine and may cause

mechanical failure. Please shut down the printer through a shutdown process such as power off and

automatic system shutdown on the LCD panel.

If metal fragments and other types of liquid leaks into the printer, it may cause mechanical malfunction.

Also, operating the printer with wet hands may cause electric shock. Use protective equipment while

using the printer.

* Latex rubber gloves can also be used in place of the nitrile gloves provided.

The warranty benefits of the printer will be forfeited if disassembled or modified artificially.

Carima will not be held liable for the loss caused by this.

For inquiries regarding “After Sale Service” and product warranty, please contact Team Viewer Service.

There are potential risks to the printer in terms of chemical composition and voltage. To prevent injury on

children and pets, please install the printer in a safe place.

If the printer power cable and USB cable are damaged due to being pulled or stepped on the rough

surface, please note that sparking or voltage malfunction may occur.

In addition, there is a risk of fire due to overheating when the power is turned off.

Setting up a printer in a place with a lot of moisture or temperature changes can cause deformation and

malfunction of the product.

[email protected]82-2-3663-8877

The printer should be used on a hard and flat floor.

When moving the printer, be sure to completely shut down the printer, and then remove the vat and

build plate so that the resin in the vat does not overflow or leak.

04

DM400A USER MANUAL

www.carima.com[email protected]82-2-3663-8877

PREPARATION AND SETUP

Printing Preparation

Preparation and Setup

To start printing, the resin must be sufficiently filled.

Please prepare resin, cleaned sweeper and build plate.

Resin Refill

* Maintenance - Resin

Press the Start button, check the amount of resin available and refill the resin.

Move the build plate to the origin position to accurately determine the amount of resin.

Pour the resin slowly so that large waves do not occur far from the resin check sensor.

When refilling the resin into the vat, it is recommended to supplement while measuring the amount of

resin.

If too much resin is filled, the printable height may be limited.

DM400A USER MANUAL

www.carima.com

05

[email protected]82-2-3663-8877

PREPARATION AND SETUP

Information on maintaining the build plate

To clean the build plate, you can scrape the hardened debris attached to

the build plate by a scraper or a spatula. If you want to print using other

resin after printing, please wipe off the stained resin before use.

Information on the use of sweeper

Before printing, please check if there is any

debris in the gap of the sweeper and remove it

before printing. Printing with foreign substances

may affect the printing result.

Information on the use of resin

Use protective equipment when using resin. Pour resin before printing and

on inevitable occasions, press the 'Pause' button and wait for a complete

stop before slowly pouring the resin into the vat.

Sweeper

* Adding the resin during output can cause bubbles and adversely affect the print.

06

www.carima.com

PREPARATION AND SETUP

DM400A USER MANUAL

www.carima.com[email protected]82-2-3663-8877

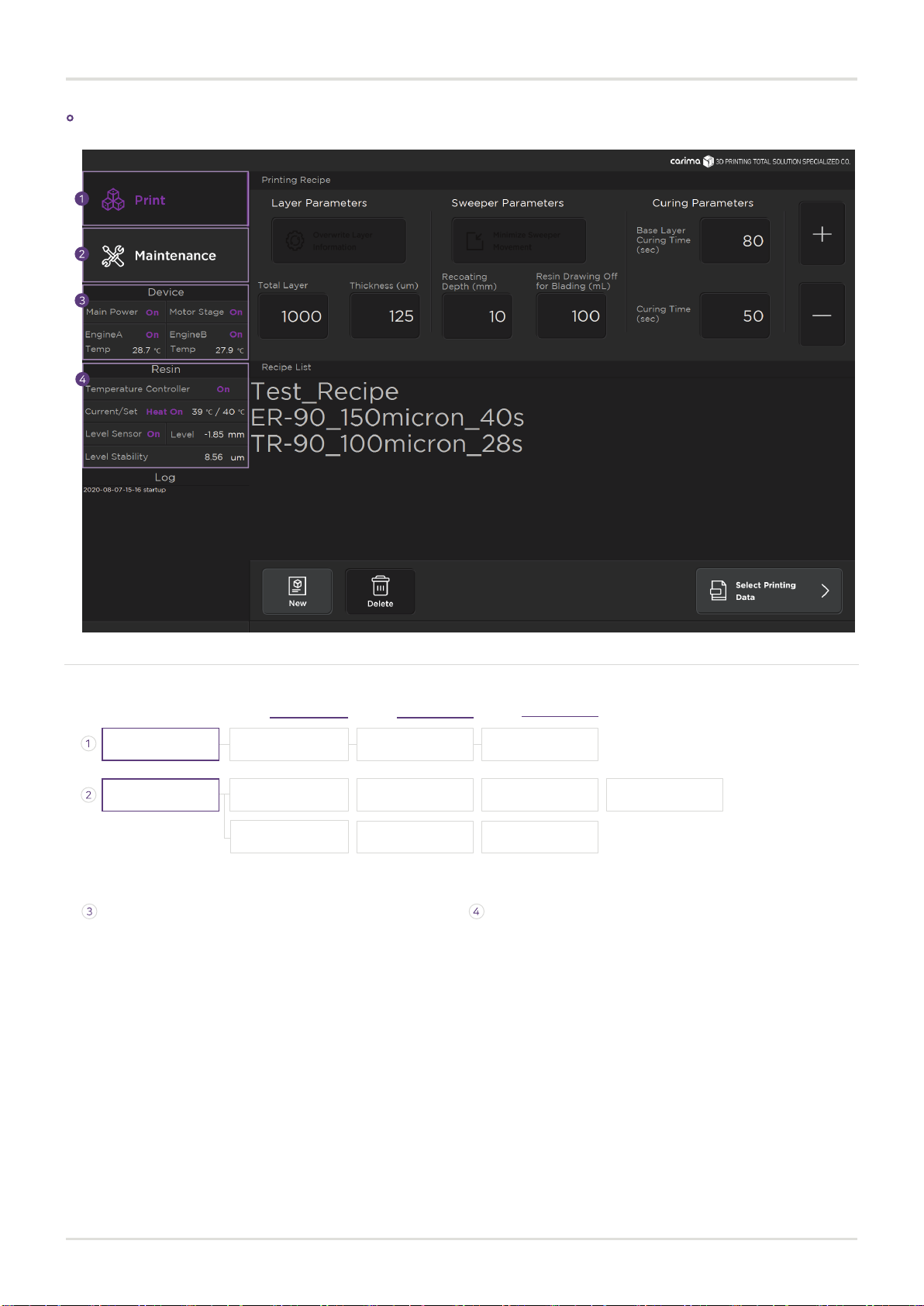

Using the LCD Panel

Use the LCD panel to set most of the settings.

Main

RUN :

Check the selected vat and usage mode

and start printing with "Run"

Vat type :

Select the vat to be used.

Regular :

Regular Vat (500mm depth)

Compact :

Low Capacity Vat (130mm depth)

Auto :

Auto Setting Mode

Manual :

Manual Setting Mode

Start Up type :

Select the mode to use.

07

www.carima.com

PREPARATION AND SETUP

DM400A USER MANUAL

www.carima.com[email protected]82-2-3663-8877

STATUS :

It shows printer status such as Main Power,

Moter Stage, Engine, and Sensor.

RESIN :

It shows the resin temperature and the level

settings.

Print

Maintenance

Select Recipe Select Data Printing

Step1

Update Admine

Step2 Step3

Resin Stage Engine Connect

Advance

Menu & Status

08

www.carima.com

DM400A USER MANUAL

www.carima.com

PREPARATION AND SETUP

[email protected]82-2-3663-8877

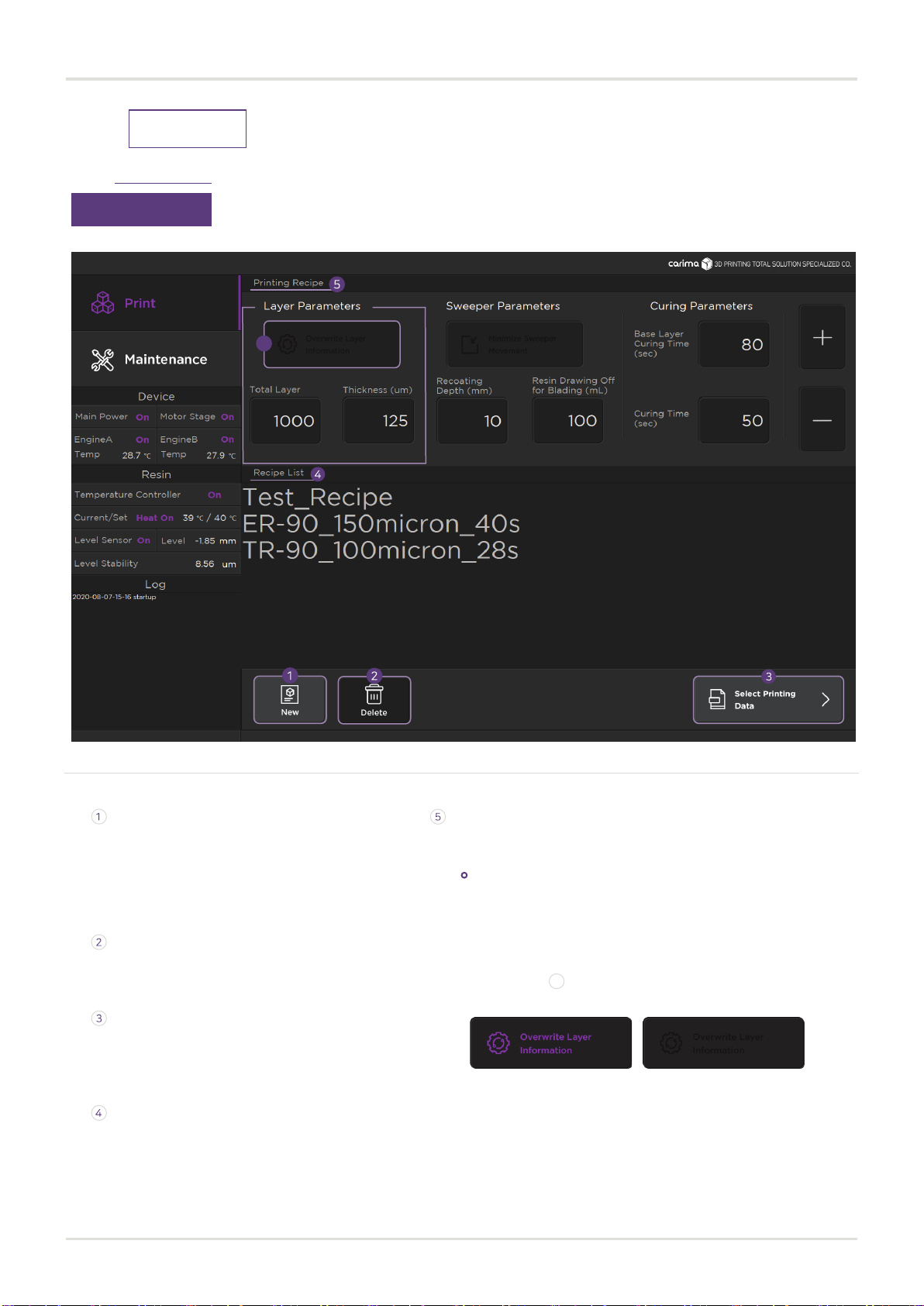

Print

Recipe List :

This is a list of recipes.

Select the recipe to be printed.

Printing Recipe :

You can change the setting value of the selected recipe.

New :

Create a new recipe.

After setting the name of the recipe, set the

printing parameter value.

Delete :

Delete the recipe.

Printing Data Select :

After completing the recipe selection, it proceeds

to the next step (output data selection).

This function ignores the value retrieved from the

printing data and prints with the currently set value.

You can activate the function with the (Total Layer, Layer

Thickness) button.

01

Step1

Select Recipe

a

Activated Deactivated

Layer Parameters :

a

Table of contents

Other Carima 3D Printer manuals