REGULATORS

ZX SECOND STAGE

©2002 Design, 2005

PG-3

OCEANIC

®

Product Service Guide

Doc. 12-2808-r01 (2/19/05)

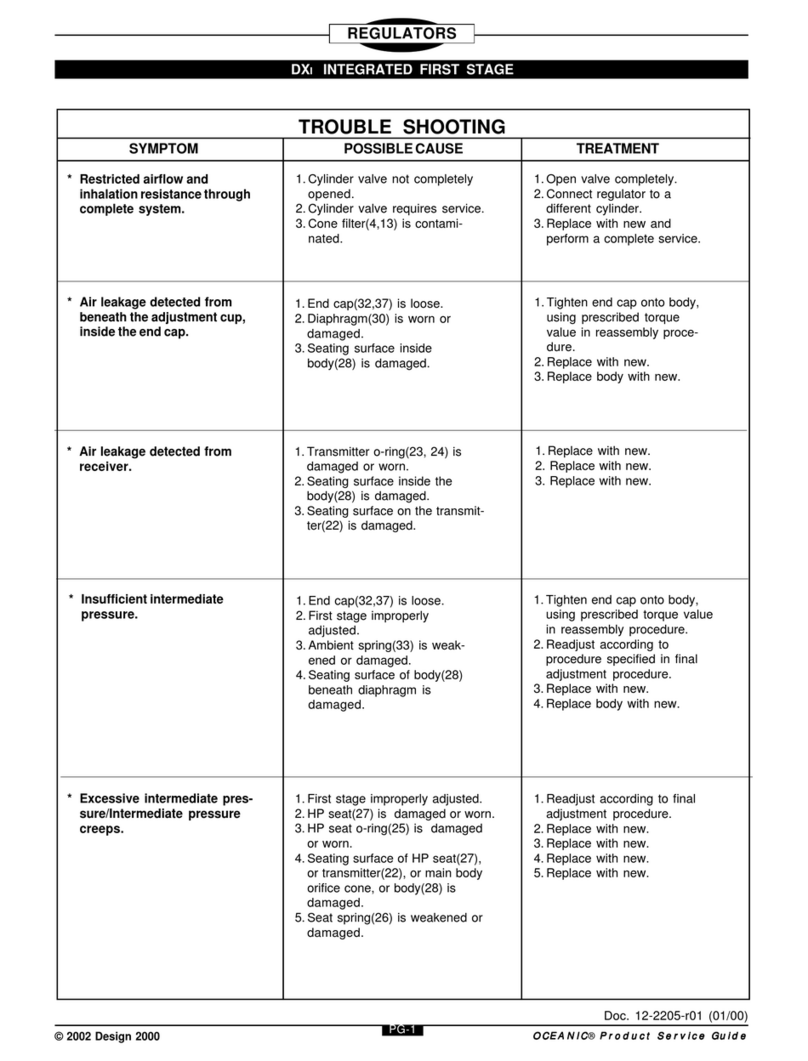

TROUBLE SHOOTING

SYMPTOM POSSIBLE CAUSE TREATMENT

* Free flow or leakage present,

with ADJUSTMENT KNOB (11)

turned in.

1. Replace with new.

2. Refer to First Stage Troubleshooting

Chart.

3. Replace with new.

4. Replace with new.

5. Turn in clockwise to adjust. (Refer

to Tuning Section.)

6. Follow correct procedure given in

Reassembly Section to tighten.

7. Remove and clean.

* Water entering Second Stage.

* ADJUSTMENT KNOB (11)

difficult to turn.

* Little or no airflow when Purge

Button is depressed.

* Rattle heard inside Second

Stage.

* Excessive inhalation resis-

tance, with ADJUSTMENT

KNOB (11) turned out.

1. Tear in MOUTHPIECE (8).

2. EXHAUST VALVE (6) distorted or

damaged.

3. DIAPHRAGM (3) distorted or dam-

aged.

4. Debris trapped beneath EXHAUST

VALVE (6).

5. FRONT COVER (2) insufficiently

tightened onto HOUSING (4).

6. Cracked or damaged HOUSING (4).

7. Mouthpiece TIE WRAP (35) too loose

or missing.

1. Debris or corrosion present on

ADJUSTMENT SHAFT (15).

2. Debris present inside ADJUSTMENT

KNOB (11).

3. Debris or corrosion present on or

inside ADJUSTMENT SPRING (17).

1. FRONT COVER (2) not sufficiently

tightened into HOUSING (4).

2. DEMAND LEVER (27) slack present.

3. ORIFICE (31) incorrectly adjusted.

1. Gravel or sand trapped inside

HOUSING (4).

2. DEMAND LEVER (27) slack present.

1. DEMAND LEVER (27) bent.

2. ORIFICE (31) incorrectly adjusted.

3. Insufficient Intermediate Pressure from

First Stage.

1. DEMAND LEVER (27) bent.

2. Excessive intermediate pressure.

3. Damaged or worn POPPET SEAT

(25).

4. Damaged ORIFICE (31).

5. ORIFICE (31) incorrectly adjusted.

6. LP HOSE ASSEMBLY (34) not

sufficiently tightened onto VALVE

HOUSING (26) Inlet Tube.

7. Trapped debris.

1. Replace with new.

2. Replace with new.

3. Replace with new.

4. Remove and clean.

5. Tighten until secure and properly

aligned.

6. Replace with new.

7. Tighten or install.

1. Disassemble and clean.

2. Flush out or disassemble if

necessary to clean.

3. Disassemble to clean or replace

with new as needed.

1. Tighten COVER RING (1) until

secure.

2. POPPET (24) not inserted properly.

Follow correct procedure given in

Reassembly Section.

3. Adjust ORIFICE (31) to correct

contact. (Refer to tuning section.)

1. Remove and clean.

2. POPPET (24) not inserted properly.

Follow correct procedure given in

Reassembly Section.

1. Replace with new.

2. Adjust to correct contact. (Refer to

Tuning Section.)

3. Refer to First Stage Troubleshooting

Chart.