Page 5 of 13

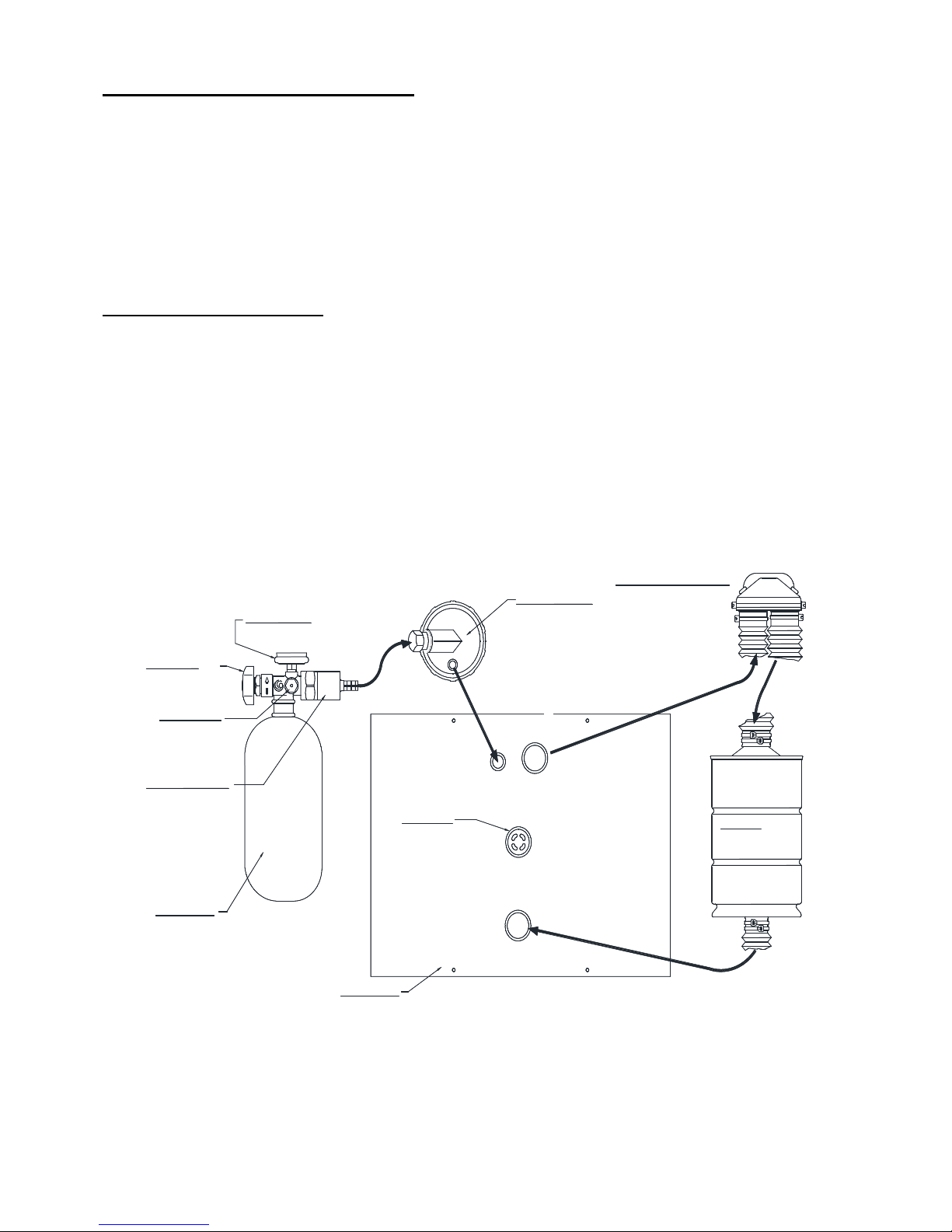

INSTRUCTIONS FOR USE

(1) Pull latch release rod.

(2) Lift and pull each latch ring to release bands.

(3) Remove cover from base. Grab the two handle straps and pull case apart, discard cover and

rubber seal.

(4) Open oxygen valve fully counterclockwise, in direction of arrow.

(5) Place neck strap over head.

(6) Pull mouthpiece toward face. The mouthpiece plug will automatically be removed from the

mouthpiece. Insert mouthpiece and breathe through mouth only. Use head strap for additional

support of mouthpiece, if required.

(7) Apply noseclips to nose. Do not attempt to inhale or exhale through your nose.

(8) Purge bag: Exhale into mouthpiece, hold breath and deflate bag by pressing on bag, then inhale

through the mouthpiece, and breathe normally. Gas will vent through the relief valve. Do not remove

mouthpiece or nose clip during purge.

(9) Adjust neck strap for comfort.

(10) Wrap waist harness around waist, clip and adjust for fit by pulling on strap end.

(11) To fit the goggles, pull the goggles over the head. After donning the goggles, prescription

eyeglasses can be donned by guiding the eyeglass temples through the channels provided.

(12) ESCAPE

Proper handling, maintenance, and other information as supplied in this manual are essential to the

effective use of the EBA-75. The user should be familiar with Instructions for Use 1-12 before

attempting to use the EBA-75.

INSTRUCTIONS FOR USE FOR USER AT REST

THE FIRST OBJECTIVE IS TO ESCAPE.

In the event escape from an oxygen deficient atmosphere cannot readily be achieved, the EBA-75

can operate for up to 6.5 hours when the user is at rest. Listed below are the steps required to extend

the oxygen supply of the EBA-75 past one hour if the unit is to be used by a man at rest. Rest is

defined as a man sitting with no activity.

(1) Purge bag: Exhale into mouthpiece, hold breath and deflate bag by pressing on bag, then inhale

through the mouthpiece, and breathe normally.

(2) When bag fills, close oxygen valve, clockwise.

(3) When bag becomes low, open oxygen valve, counterclockwise.

(4) Repeat steps 2 and 3 until no longer at rest.

Note: Performance of the EBA-75 under the User At Rest procedure, not a requirement of 42 CFR

Part 84, Subpart O, has not been evaluated by NIOSH/MSHA.