Unit with the oor-type

(NJ-80) NEJIKURA installed

Unit with the tower-type

(T-510) NEJIKURA installed

Do not allow screws cover top surface of the rail groove. (The

screws must be positioned about 2 to 3 mm lower than top

surface of the groove.)

– 6–

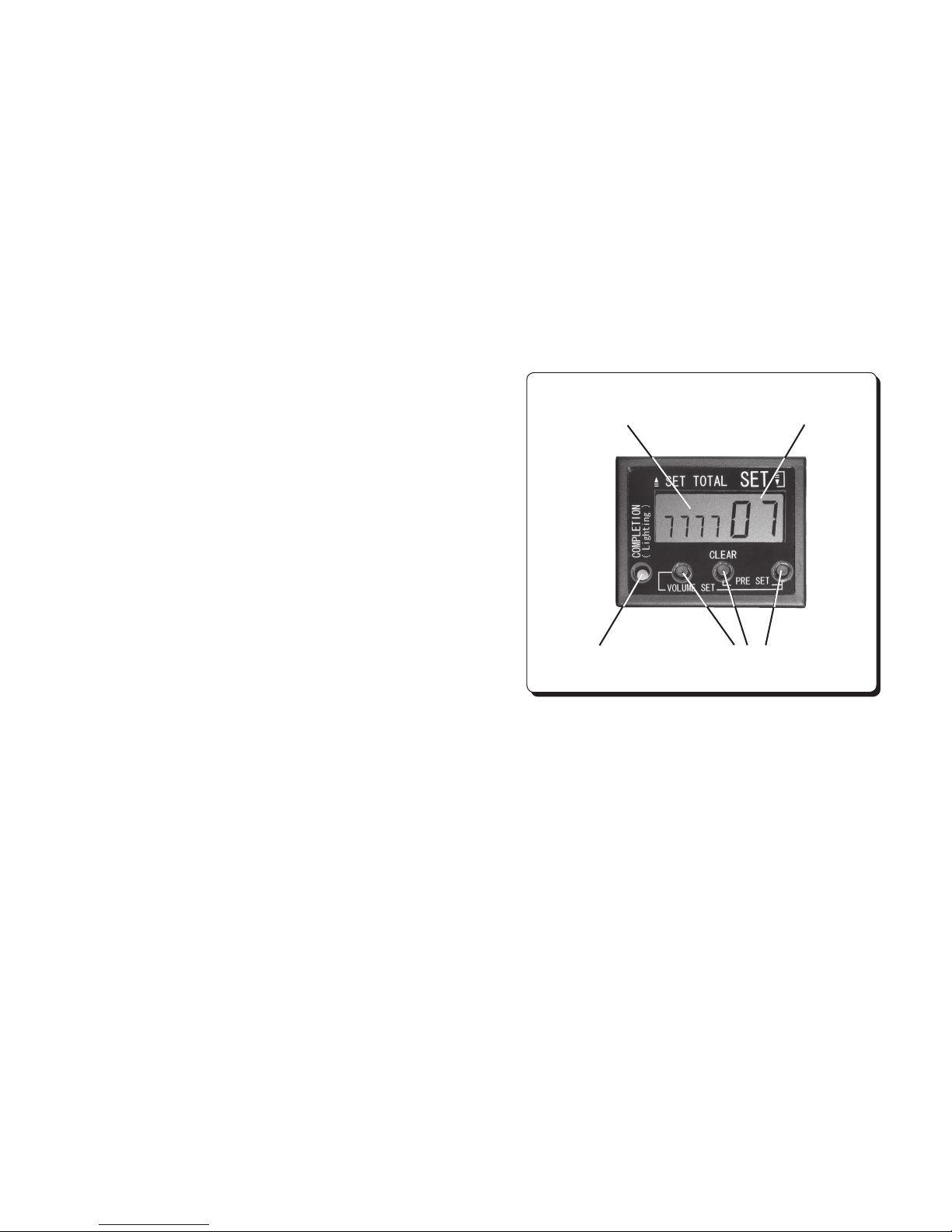

5. Getting this machine ready

5.1 Supply of Screws

Loading this machine with too many screws could

adversely affect their alignment and transfer.

The approximate maximum supply of screws is illustrated

in the gure at right. Consult this gure for loading screws.

• Turn the power switch on, then off to move the Bin scooping plate to the

lower position.

• Load screws to a roughly 2 to 3 mm lower than the top surface of the rail

groove. Check to make sure that the top surface of the rail groove is not

covered by the screws.

• Adjust the supply of screws by observing behavior of this machine in

operation.

This machine comes with an overload protection circuit.

The protection circuit trips when the moving parts of this machine are

overloaded, such as when screws being stuck in the moving parts, or too

many screws being put in the screw bin.

Actuation of the overload protection circuit

If the moving parts of this machine are overloaded, the drive motor reverses

for a predetermined period of time and then returns to forwarding. When

the overload imposed on the moving parts of this machine no longer

exists during reversing, the drive motor returns to normal forwarding. If

the overload imposed on the moving parts of this machine persists during

reversing, the drive motor reruns the sequence of reversing, forwarding,

reversing, forwarding and so forth for a predetermined period of time before

it is powered off. The escaper disc continues operating, though.

Thus explained, if the drive motor is powered off, turn off the power switch

and remove the overload imposed on the moving parts of this machine.

For example, if you have put too many screws in the Screw bin, correct the

supply of screws. If screws or any other objects are stuck in the moving

parts of this machine, remove them.

After the overload has been removed, turn on the power switch to put this

machine back into operation (power-on reset).

• A screw stock option, NEJIKURA is available which loads screws

automatically to maintain the supply of screws. Please check with your

dealer if you need this option.