5

B

1

2

3

4

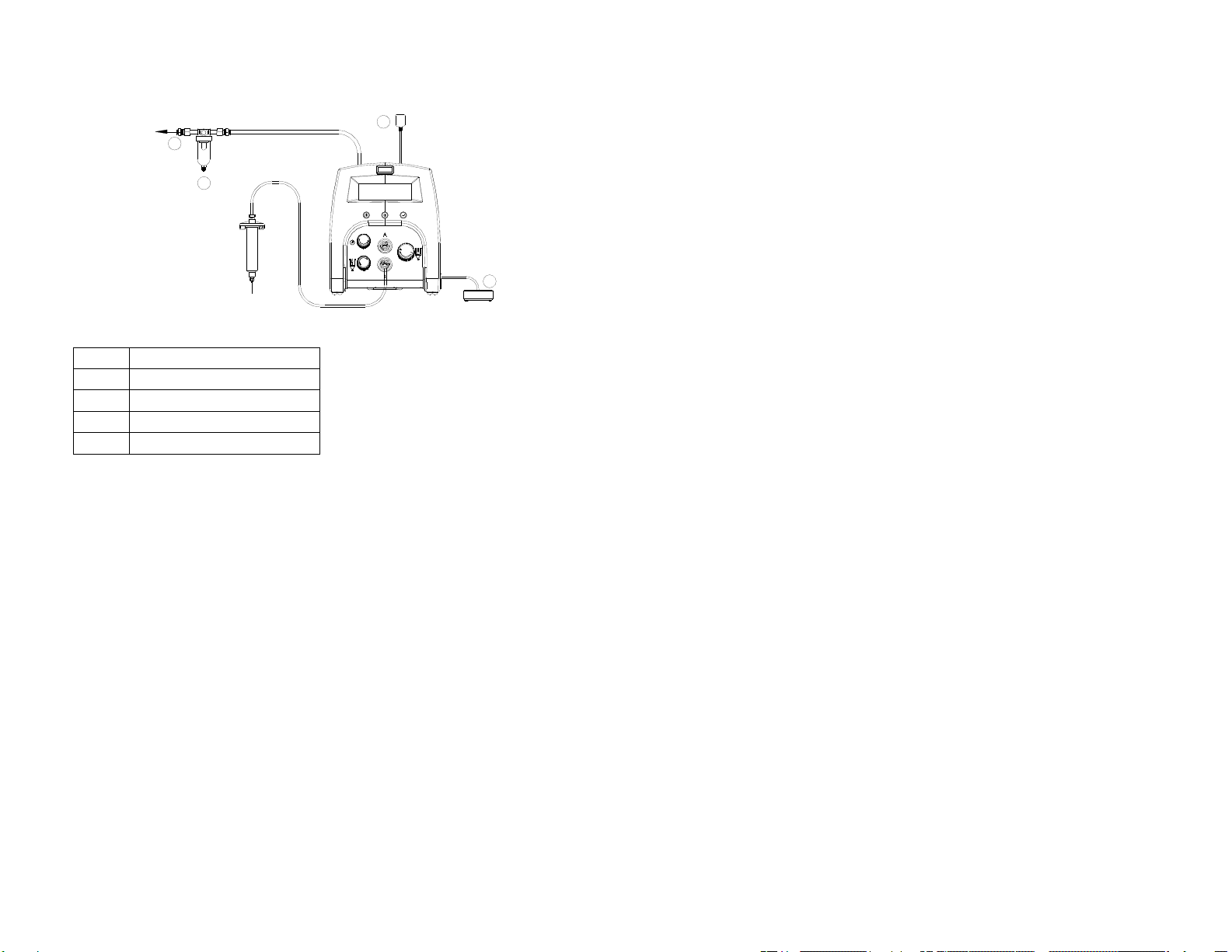

5CONNECTING THE UNIT

CAUTION: A 5-micron filter TSD800-6, not included, must be installed with the unit

to ensure proper air filtration.

Figure 2.0

6SETUP INSTRUCTIONS

Refer to Figure 1.0

6.1 Manual/Purge Dispense Cycle Setting:

1. Turn on the unit by pressing the Power button (1)

2. Press the Mode button (2) until “PURGE” appears on the Display.

3. Turn up the air pressure by rotating the Air pressure regulator knob (5)

until the desired pressure is indicated on the Display

4. After filling the barrel or using pre-packaged adhesive, attach syringe to

receiver head assembly. Make certain that the syringe locks into place

5. Connect the plug end of the receiver head assembly to one of the air

dispense outlet (6).

6. If vacuum “suck back” is needed, rotate the Vacuum regulator (7) counter

clockwise until the desired vacuum pressure is indicated on the Display

7. Press and hold the Foot switch to activate dispensed cycle. (The

Manual/Purge Mode is now activated)

6.2 Automatic Dispense Cycle Setting

6.2.1 Program selection

1. Press the reset button (3) until “P:” is flashing

2. Rotate the Setup Control Knob (8) to select desired program

6.2.2 Time setting

1. Press the Mode button (2) to select “TIMED” mode

2. Press and release the reset button (3) until the colon cursor (:) in the

“TIME:” is flashing.

3. Rotate the Setup control knob (8) to set the desired dispense time

4. Depress Foot switch to activate timed dispensed cycle

Items Description

1 To Air Source

2 Air Filter (Not Included)

3 Power Adapter

4 Foot Switch

6

6.3 Teach Mode Setting

In the teach mode, the unit will accumulate time as long as the foot switch

is depressed. This is helpful in determining dispense time required when

dispense output is unknown.

1. Press the Mode button (2) to select “TEACH” mode.

2. Press and release the reset button (3) until the dispense time = 0.000S

3. Press and hold down Foot switch. Dispense time will accumulate

during this time.

4. Release Foot switch when proper amount of fluid is dispensed.

5. Press the Mode button (2) to switch the “TIMED” mode.

6. The dispenser is now set to repeat this time cycle.

6.4 Multiple Shots Setting:

Up to ten separate individual or sequenced shots can be stored in the

TS350/TS355.

1. Follow steps in section “6.2 Automatic Dispense Cycle Setting” to

set dispense time in desired programs.

2. Press both the Reset button (3) and the Power button (1)

simultaneously to activate sequence program mode.

3. Rotate the Setup Control knob to select total number of program to be

dispensed in sequence

4. Press both the Reset button (3) and Power button (1) to exit Multiple

Shots mode.

6.5 Cycle Counter

The cycle counter records the numbers of automatic dispense cycle being

activated. Up to 65,535 cycles can be recorded. This number is shown at

the lower right hand corner of the LCD. To reset the counter, press and

hold the Reset button (3) and the Mode button (2) simultaneously until the

counter shows “0”.

6.6 Change Pressure and Vacuum Unit Display

1. Press and release the reset button (3) until the colon cursor (:) in the

“PRESSURE:” or “VACUUM:” is flashing

2. Rotate the Setup control knob (8) to select desired unit display