Safety

2. Foreword

This Manual gives the precautions to be taken in using this product so it can be operated safety and

efficiently.

Before starting to use this machine, carefully read this manual and master how to operate it.

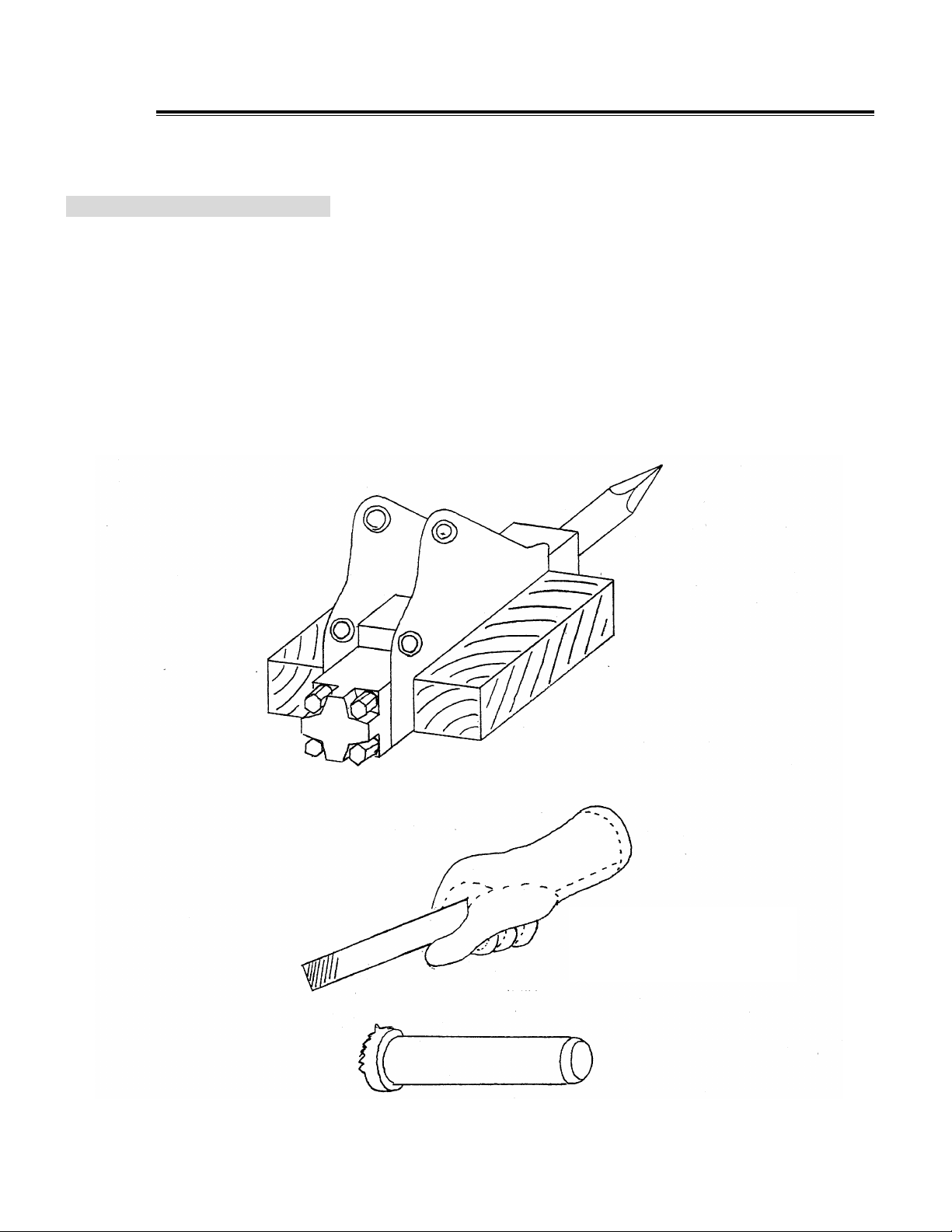

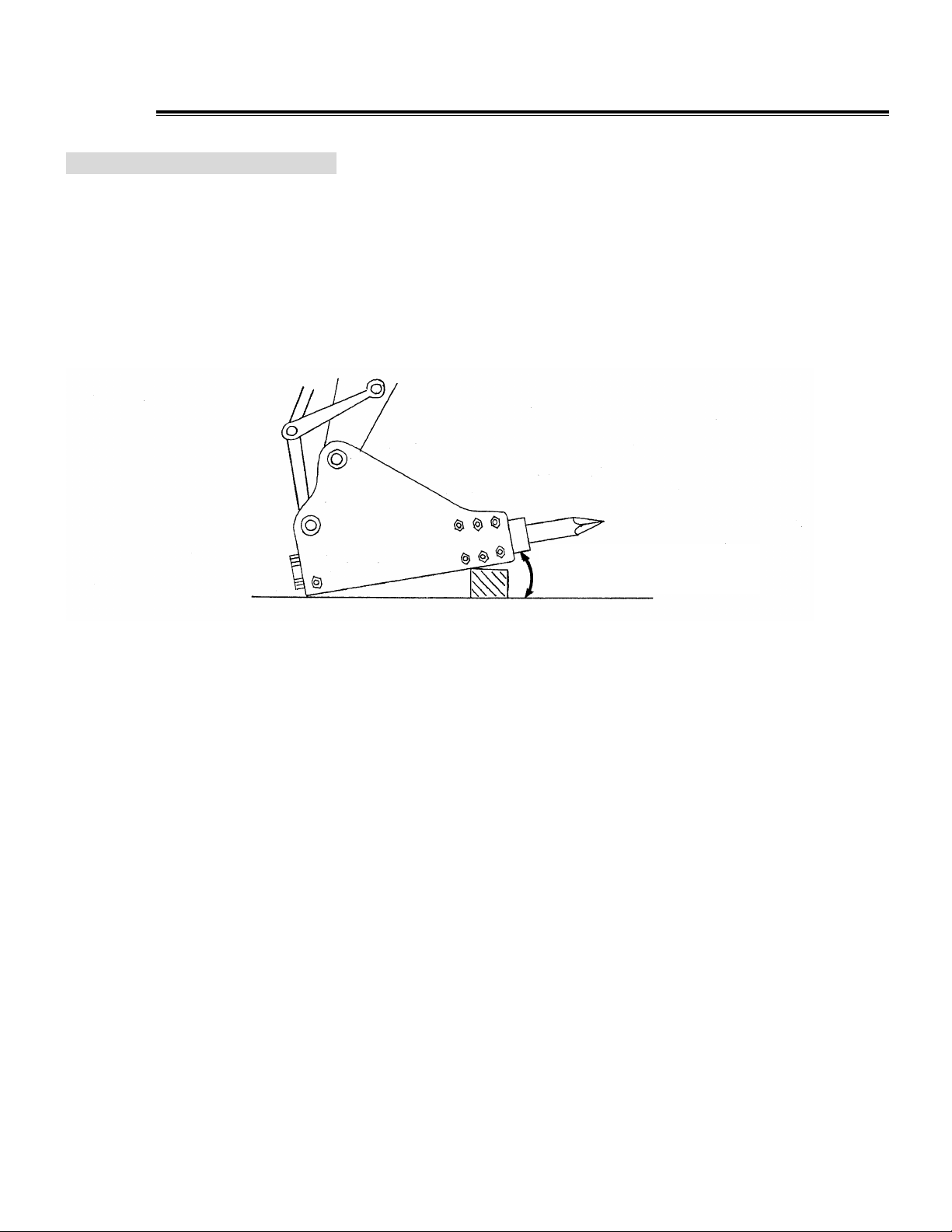

This machine is the attachment used as mounted on the hydraulic backhoe. Therefore, it is necessary for

its user to read and understand the Operation Manual for the hydraulic backhoe also.

3. People make the difference

People who use or operate hydraulic hammers must be:

COMPETENT

●Physically-good vision, hearing, coordination, and capable of safety performing all functions required for

the operation of the machine

●Mentally-able to understand and apply established rules, regulations, and safe practices. Be alert, using

good judgment for safety to themselves and others. Desire to do their job correctly and in a responsible

manner.

●Emotionally-be calm and capable of withstanding stress and make judgments concerning their own

physical and mental conditions.

●Trained-have read and understood the operator's instructional manual, the load rating chart if applicable,

hand signals chart and warning decals, and maintenance aspects of the machine.

●Licensed-if required by law.

Careless operation of this machine can result in death or serious injuries.

The operators and maintenance personnel are asked to thoroughly read this Manual

and the Operation Manual for the hydraulic backhoe before starting operation or

maintenance work.

Keep this Manual near the machine as a handbook for ready reference. All

personnel are advised to read it at periodical intervals.

●Always keep this manual handy, and read it repeatedly.

●If this Manual should be lost or damaged, promptly place an Manual together with the

machine.

●When you transfer the machine, be sure to hand over the Manual together with the

machine.

●As a result of continuous improvements, the current machine may differ in detail specification

from machines sold in the past. If you have any questions in this regard, please ask our

Company or its distributor.