CONTENTS

1. CONFIGURATION..................................................................................... 1 - 1

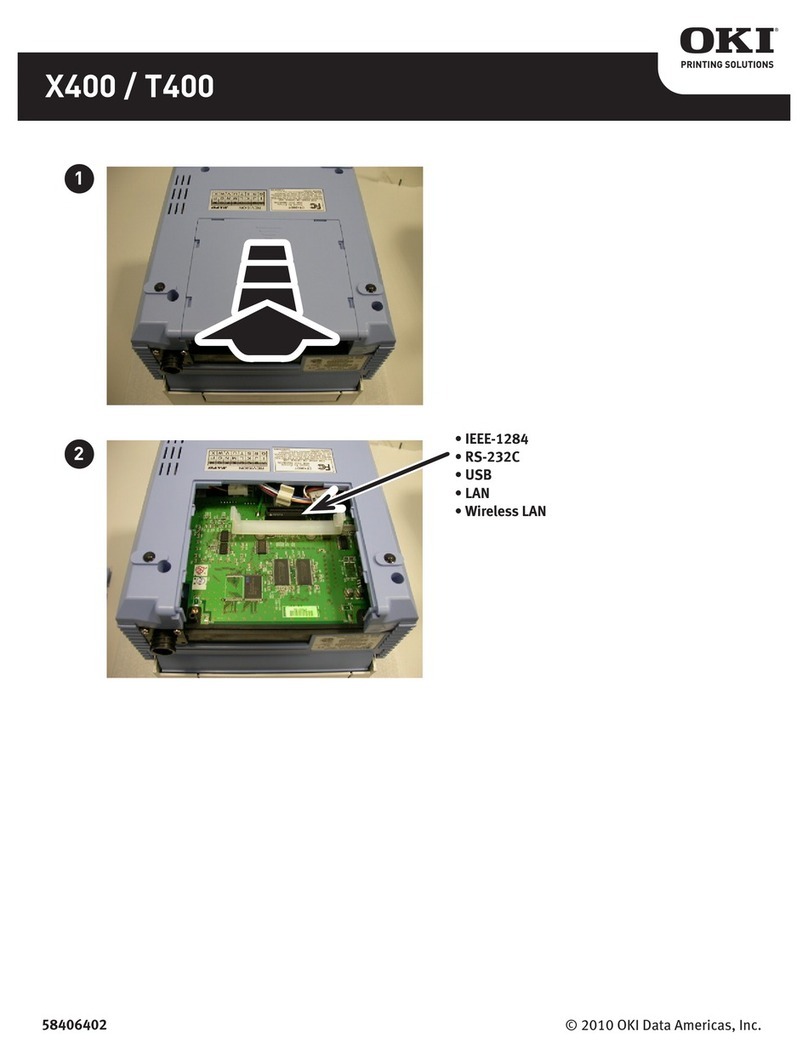

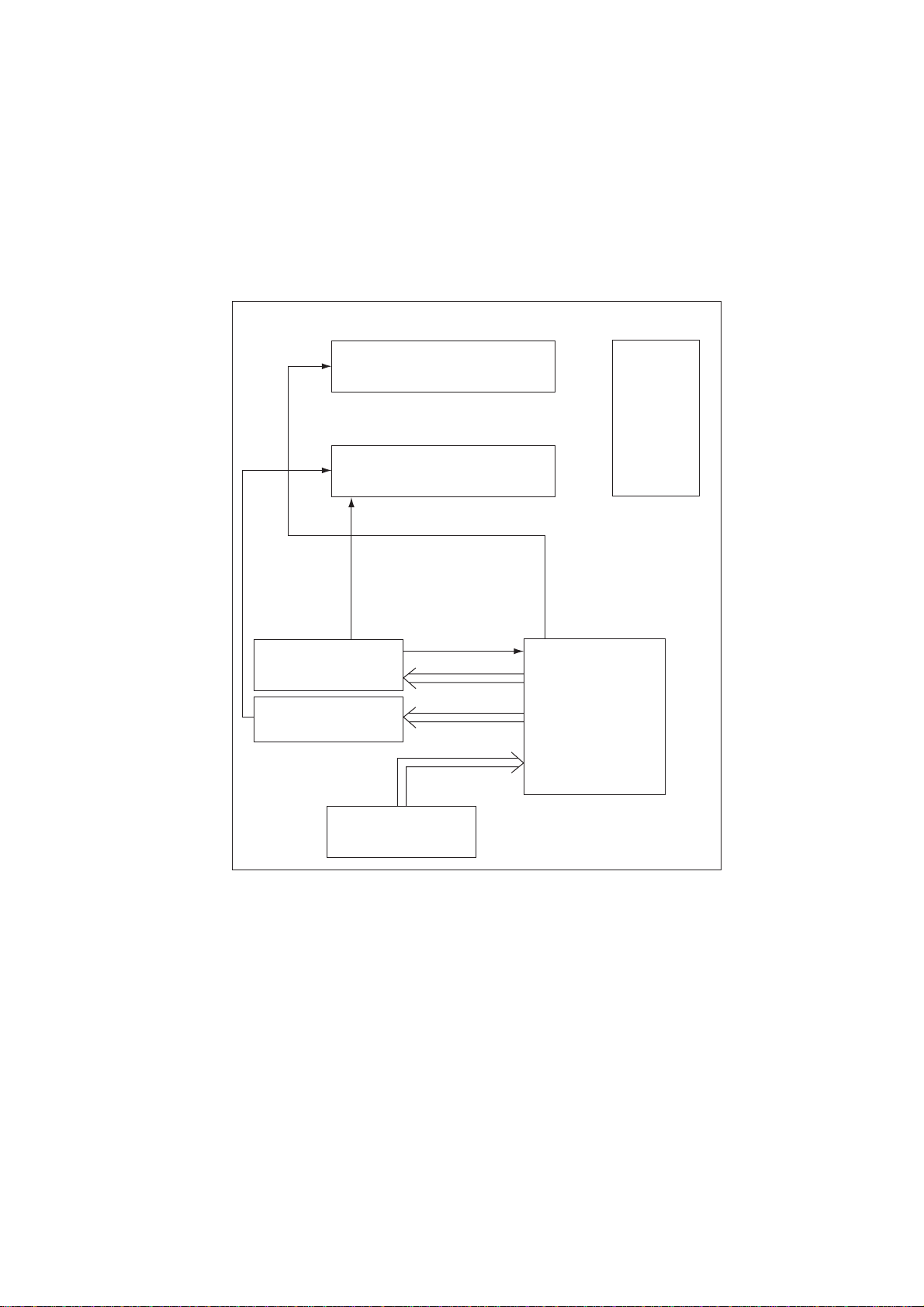

1.1 System Configuration ........................................................................ 1 - 1

1.2 Printer Configuration .......................................................................... 1 - 2

1.4 Specification ...................................................................................... 1 - 3

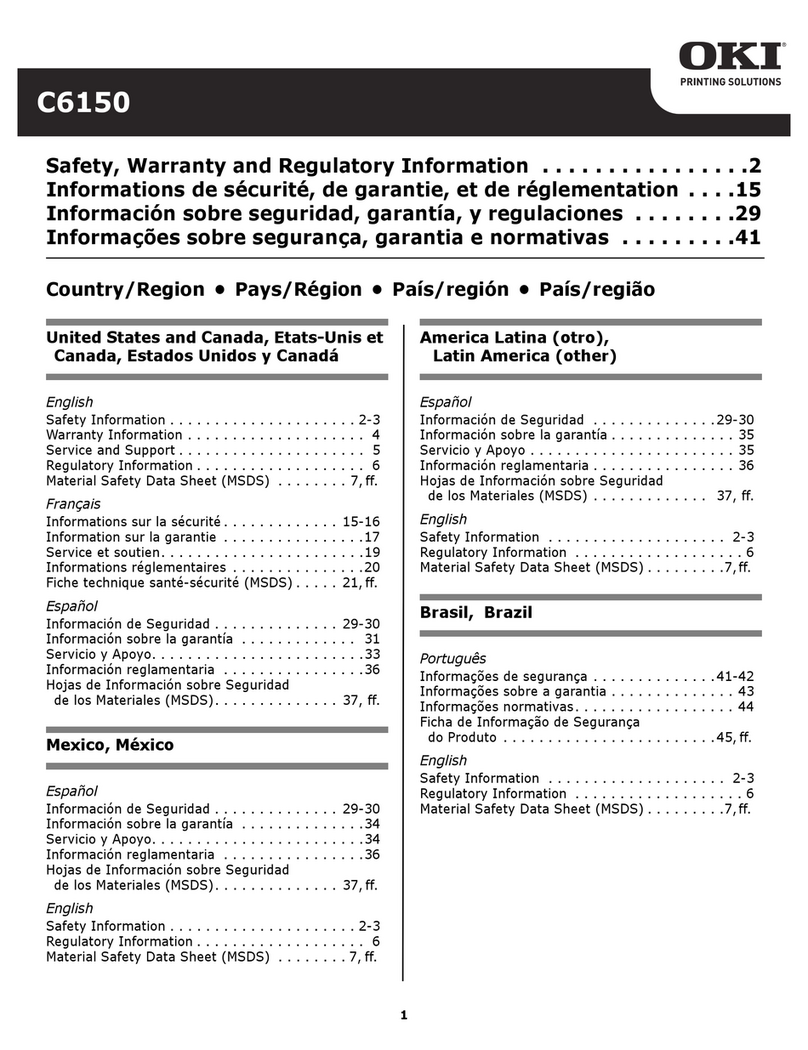

1.5 Safety Standards ............................................................................... 1 - 5

2. OPERATION DESCRIPTION .................................................................... 2 - 1

2.1 Main Control Board ............................................................................ 2 - 3

2.2 Power Supply Unit ............................................................................. 2 - 4

2.3 High-Voltage Power Supply Board .................................................... 2 - 4

2.4 Electro-Photographic Processor ........................................................ 2 - 6

2.5 Electro-Photographic Process ........................................................... 2 - 10

2.5.1 Explanation of Each Process Operation.................................................. 2 - 12

2.6 Paper Jam Detection ......................................................................... 2 - 18

2.7 Toner Low Detection.......................................................................... 2 - 18

2.8 Cover Open ....................................................................................... 2 - 21

2.9 Detecting I/D Unit existence .............................................................. 2 - 21

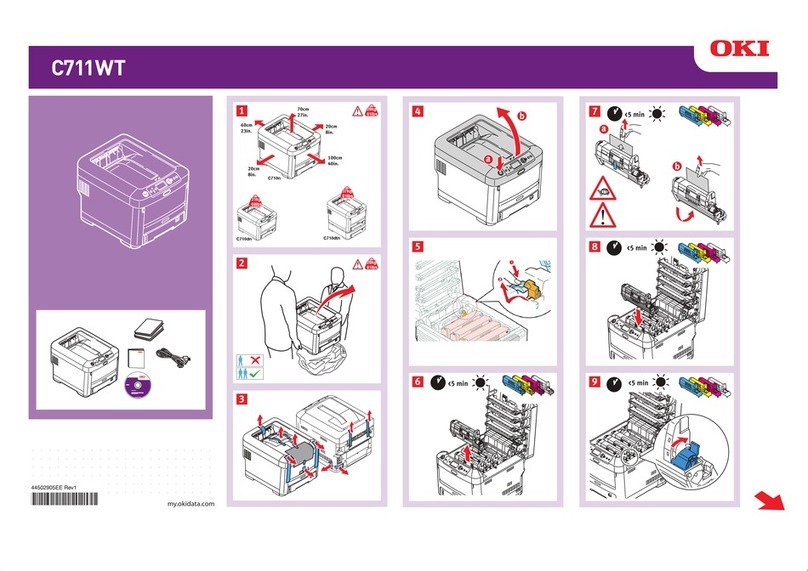

3. PARTS REPLACEMENT........................................................................... 3 - 1

3.1 Precautions for Parts Replacement ................................................... 3 - 1

3.2 Parts Layout....................................................................................... 3 - 3

3.3 Replacing Parts ................................................................................. 3 - 6

3.3.1 Hopper Plate ........................................................................................... 3 - 6

3.3.2 LED Head and Head Spring .................................................................... 3 - 7

3.3.3 Transfer Roller ......................................................................................... 3 - 8

3.3.4 How to remove Cover Upper Assy .......................................................... 3 - 9

3.3.5 Upper Cover Assy ................................................................................... 3 - 10

3.3.6 High-Voltage Power Supply Board (P2H) ............................................... 3 - 11

3.3.7 Top Cover Assy and Flat Cable Assy ...................................................... 3 - 12

3.3.8 Paper Holder ........................................................................................... 3 - 13

3.3.9 Side Plate M and Idle Gear ..................................................................... 3 - 14

3.3.10 Heat Assy ................................................................................................ 3 - 15

3.3.11 Drive Shaft E (Eject) and Eject Roller ..................................................... 3 - 16

3.3.12 Pressure Roller B (Back Up Roller) ......................................................... 3 - 17

3.3.13 Separator Guide ...................................................................................... 3 - 18

3.3.14 Pulse Motor (Main) .................................................................................. 3 - 20

3.3.15 Hopping Shaft Assy ................................................................................. 3 - 21

3.3.16 Regist Roller ............................................................................................ 3 - 22

3.3.17 Paper Sensor E, Paper Sensor Exit and Toner Sensor Assy ................. 3 - 23

3.3.18 Base Plate ............................................................................................... 3 - 24