41057610TH Rev. 1 3 /

CONTENTS

1.SPECIFICATIONS............................................................................................6

1.1 Basic System Configuration.............................................................................................6

1.2 Printer Specifications.......................................................................................................7

1.3 Option Specifications.......................................................................................................8

1.4 Basic Specifications........................................................................................................9

2.OPERATION...................................................................................................12

2.1 Main Control Board (PCE PCB)....................................................................................13

2.2 Engine Control Board (PX4 PCB)..................................................................................16

2.3 Power/Units....................................................................................................................17

2.4 Mechanical Processes...................................................................................................18

2.4.1 Electrophotographic processing mechanism....................................................19

2.4.2 Paper running process.....................................................................................25

2.5 Sensors..........................................................................................................................34

2.5.1 Paper related sensors......................................................................................34

2.5.2 Other sensors...................................................................................................35

2.6 Correction of Color Deviation.........................................................................................36

2.7 Transfer Control according to Environmental Changes

(Room Temperatures and Relative Humidities).............................................................36

2.8 Form Jam Detection.......................................................................................................37

2.9 Cover Opening...............................................................................................................37

2.10Toner Low Detection......................................................................................................38

2.11Page Size Detection......................................................................................................39

2.12Power-on Processing.....................................................................................................40

2.12.1Self-diagnostic test...........................................................................................40

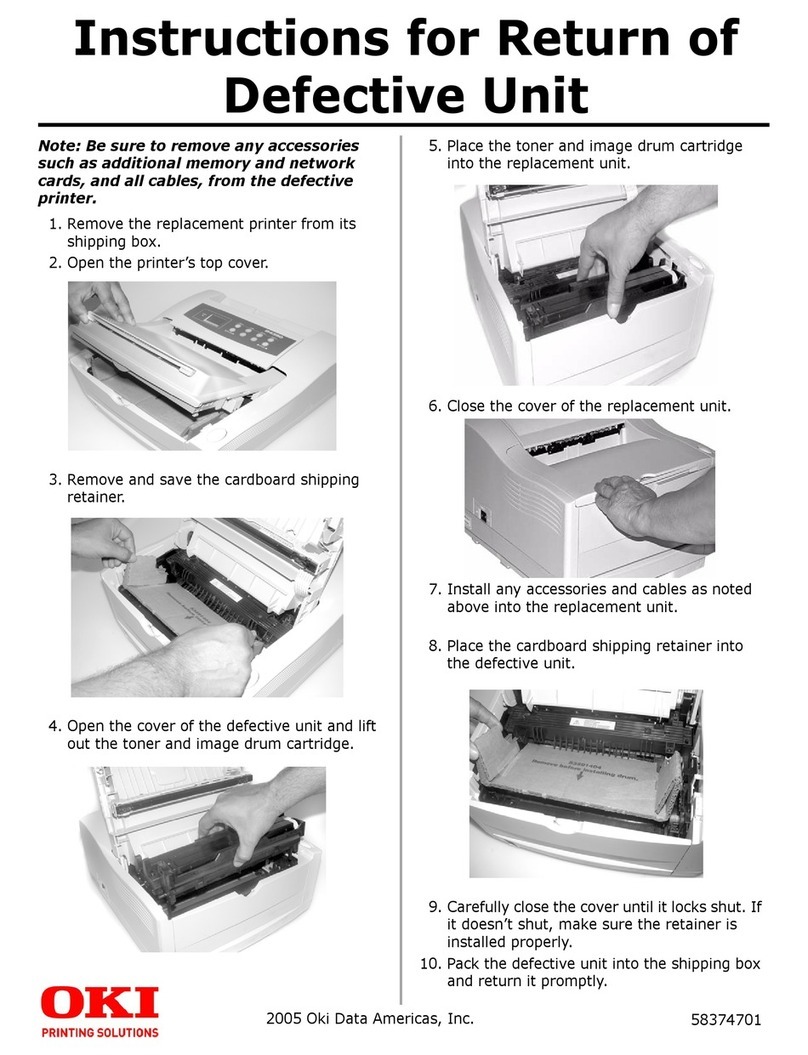

3.PARTS REPLACEMENT................................................................................41

3.1 Precautions for Parts Replacement...............................................................................41

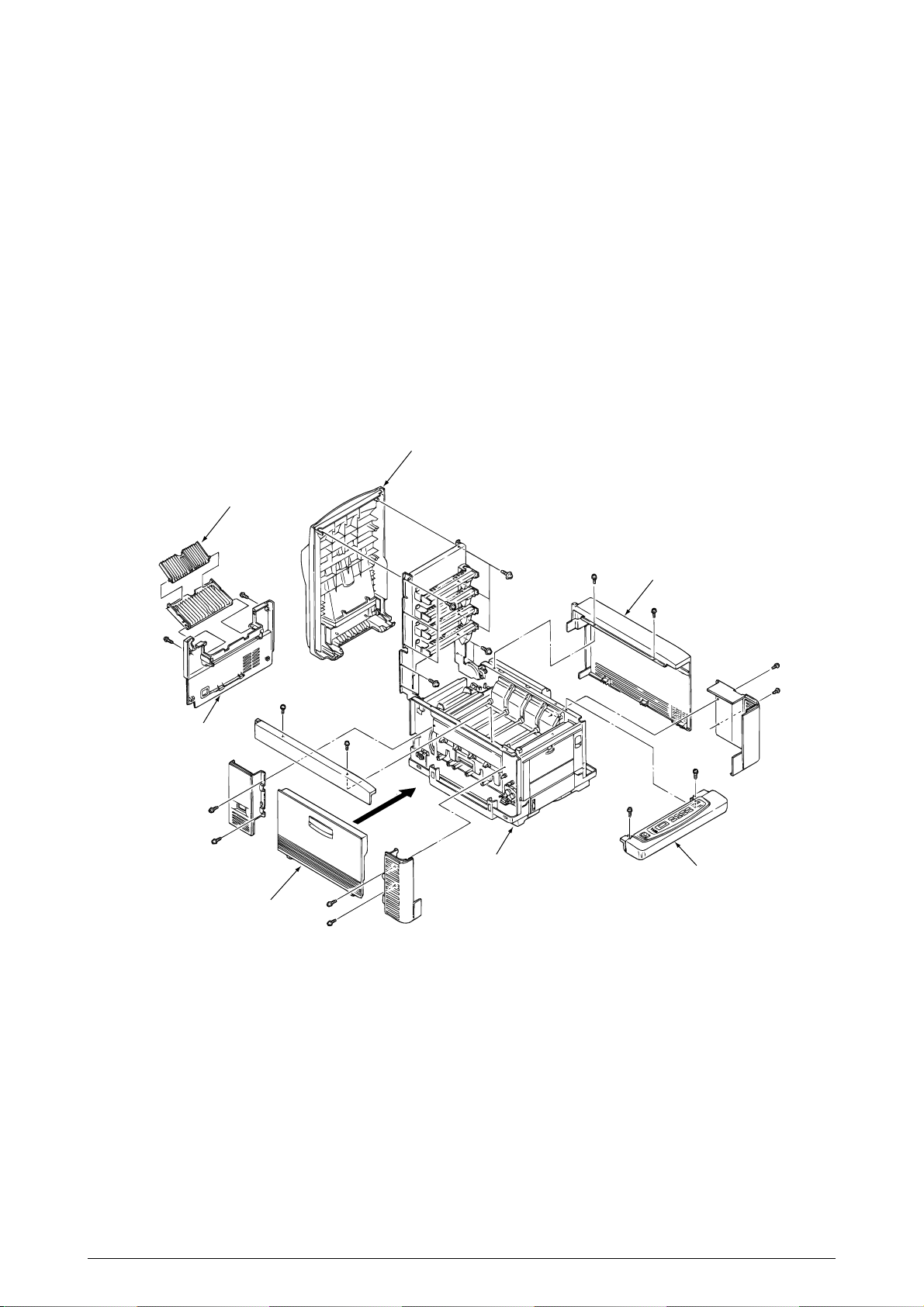

3.2 Parts Layout...................................................................................................................43

3.3 How to Change Parts.....................................................................................................47

3.3.1 Cover Assy Rear..............................................................................................48

3.3.2 Motor-Fan (80-25)............................................................................................49

3.3.3 Paper Eject Assy..............................................................................................50

3.3.4 Cover Assy Stacker, Guide Eject FD Assy.......................................................51

3.3.5 Frame Assy Upper............................................................................................52

3.3.6 Plate Support Assy...........................................................................................53

3.3.7 Limiter 2way (L), (R) / Plate Guide (L) , (R)......................................................54

3.3.8 Cover55

3.3.9 PCB Assy : PCE...............................................................................................56

3.3.10Motor Fan (CU).................................................................................................57

3.3.11PXF PCB/PX4 PCB..........................................................................................58

3.3.12Gear Heat Assy................................................................................................59

3.3.13Main Motor (A), (B) Assy..................................................................................60

3.3.14Gear One-way (Z30).........................................................................................61

3.3.15Motor Assy BT..................................................................................................62

3.3.16Power Supply Unit, Holder Inlet, Sheet Insulation............................................63

3.3.17Sensor Assy Box Toner....................................................................................64

3.3.18Square-shaped Connector...............................................................................65

3.3.19Hopping Motor..................................................................................................66

3.3.20Gear One-way..................................................................................................67

3.3.21Feeder Unit Front.............................................................................................68

3.3.22Manual Feed Hopper Assy...............................................................................69

3.3.23Guide Paper Input Assy....................................................................................70

3.3.24Two Lever Input Sensors, Lever 2nd Feed Sensor..........................................71

3.3.25Roller Registration, Roller Assy Hopping.........................................................72