9

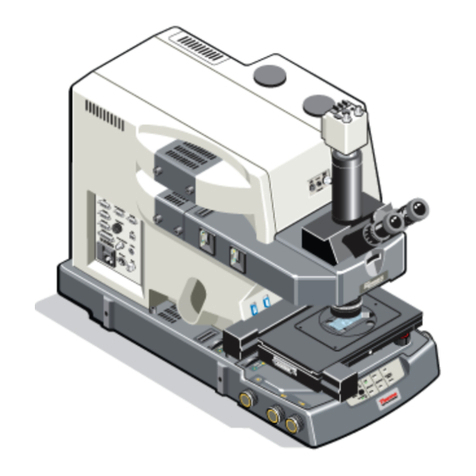

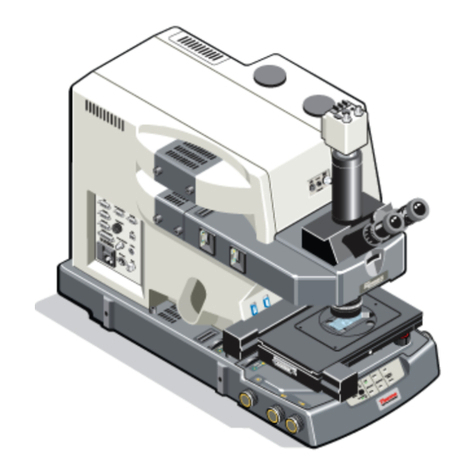

World-class resolution and precision.

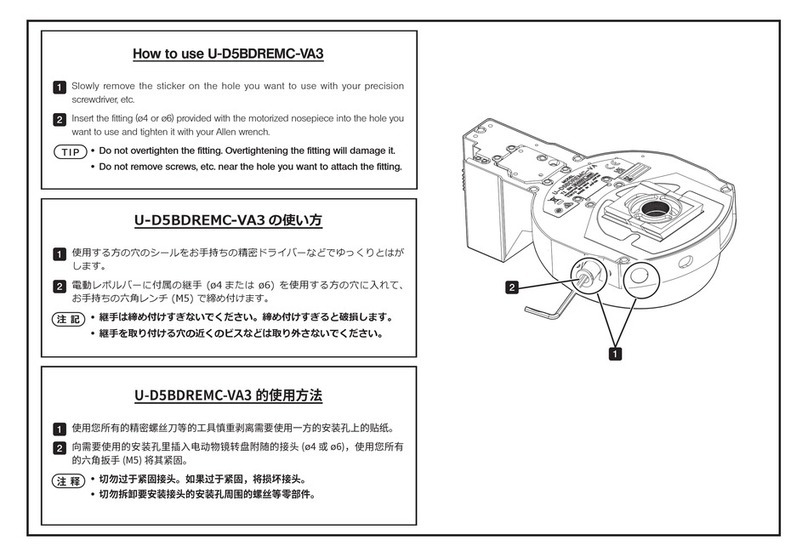

Objective lens

Circular confocal

pinhole

LED light

CCD

Photomultiplier

Laser

● World’s highest level of resolution

The optical system designed exclusively for use with 408-nm

laser light (violet opt system) prevents the occurrence of

aberrations associated with the use of a short-wavelength light

source, and brings the highest performance out of the 408-nm

light source. Such a high level of resolution has been made

possible by the confocal optical system having an optimized

circular pinhole and the high-

speed XY scanner with the

MEMS technology of Olympus.

With the world's highest-level

planar resolution, a line or space

of 0.12 µm can be resolved.

Additionally, the 0.01 µm height

resolution supports the user in

undertaking measurements of

microscopic surface profiles.

Basic concept of a light path in the violet opt system

Basic concept of the two-dimensional scanner

Multiple points

at peak

intensity

Intensity

Height

MEMS scanner

Incident light

Scan pattern

0.12 µm line and space 14,400x

● Further advanced, the world’s highest level of

repeatability

Advanced optical techniques of Olympus accumulated over

years have made possible the planar measurement

repeatability of 3σ= 0.02 µm and the height measurement

repeatability of 3σ= 0.04 + 0.002L mm (L = measured length

in µm). A guide with high performance in terms of straightness

and a high-precision linear scale are used for Z-axis scanning.

These parts combined with the further advanced CFO search

function contribute to very high level of repeatability. The high

degree of reliability makes it possible for LEXT to meet the

highly demanding needs of diverse fields of research and

industry.

● Measurements that can be trusted

Highly reliable data can be provided based on the strict

traceability system that is linked with the JCSS (Japan

Calibration Service System). JCSS Japan Calibration Service System

Block Gauge

OLYMPUS

Stabilized He-Ne Laser

Calibration standard Calibration block

LEXT (OLS3100)

Traceability chart

Japan (NMIJ/AIST)

CFO search function

The original I-Z curve is

drawn based on the upper,

high-luminance points, and

maximum luminance values

are calculated with high

accuracy by using an

advanced formula. The high

repeatability of LEXT is

made possible through the

height data being obtained

in this process.