• D n t exceed v ltage rating n the label l cated n the t p f the instrument

h using.

• Always disc nnect p wer bef re changing signal and p wer c nnecti ns.

• D n t use this instrument n a w rk bench with ut its case f r safety

reas ns.

• D n t perate this instrument in flammable r expl sive atm spheres.

• D n t exp se this instrument t rain r m isture.

EMC:

• Whenever EMC is an issue, always use shielded cables.

• Never run signal and p wer wires in the same c nduit.

• Use signal wire c nnecti ns with twisted-pair cables.

• Install Ferrite Bead(s) n signal wire cl se t the instrument if EMC pr blems

persist.

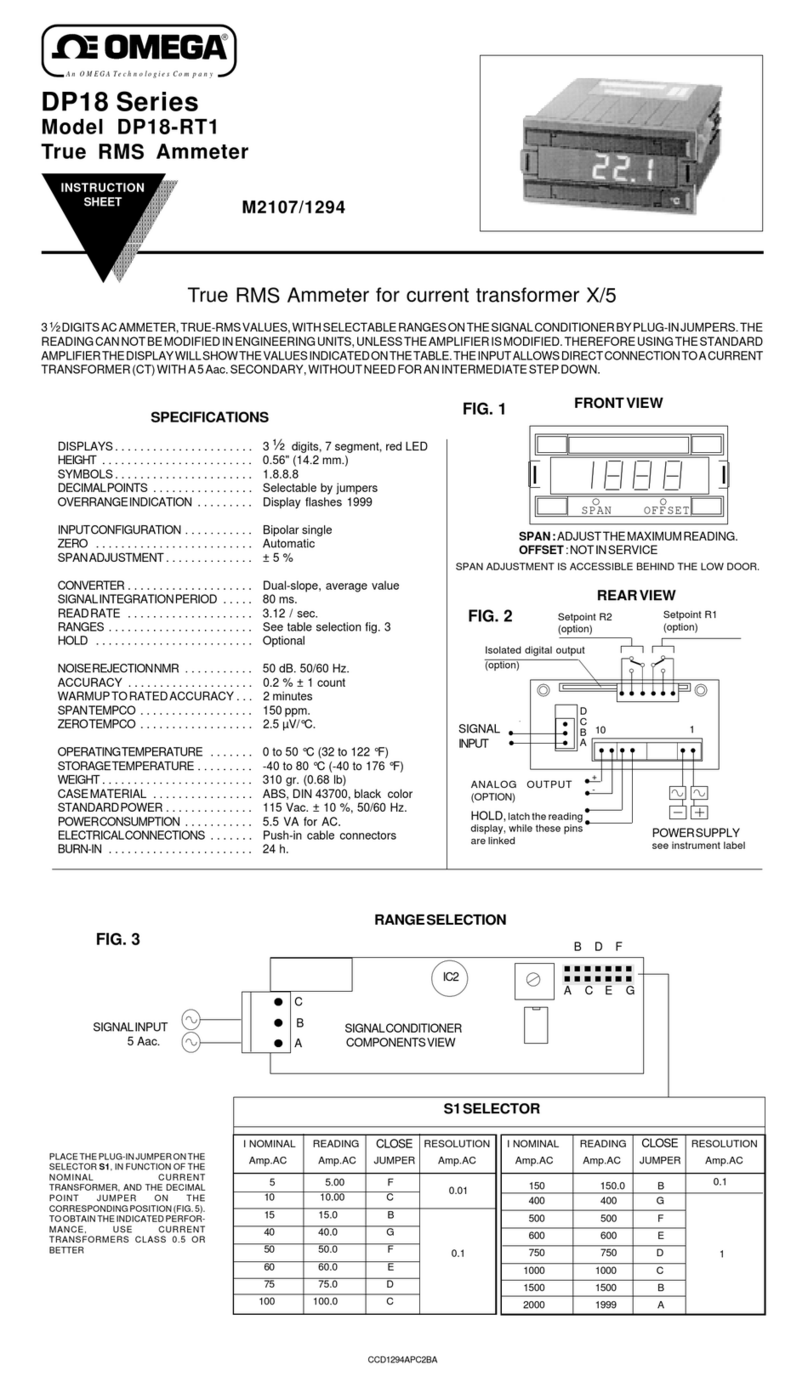

Mount the Unit

1. Cut a panel pening using the dimen-

si ns sh wn t the right.

2. P siti n the unit in the pening, making

sure the fr nt bezel is flush with the

panel.

3. Install retaining clips n b th sides f

the meter and tighten against the panel.

Wiring

Warning: Do not connect AC power to yo r device ntil yo

have completed all inp t and o tp t connections. This device

m st only be installed by a specially trained electrician with

corresponding q alifications. Fail re to follow all instr ctions

and warnings may res lt in inj ry!

1. Rem ve the panel at the back f the unit.

2. L cate the TB1 c nnect r.

3. Insert the c rrect wire in each terminal as sh wn in the f ll wing figure

and tighten the l ckd wn screws.

4. Tug gently n the wires t verify the c nnecti ns.

External F se Req ired:

Time-delay, UL 248-14 listed Time-lag, IEC 127-3 rec gnized

175 mA (115 Vac line) 125 mA (115 Vac line)

80 mA (230 Vac line) 63 mA (230 Vac line)

AC Powered Unit Connections

START HERE

Wiring (continued

When using DC p wer, d n t use internal excitati n r Is lated

Anal g Output f r high c l r brightness. F r l w r medium

brightness, internal excitati n is limited t 24 V @ 25 mA; 5 V, 10

V, 12 V @ 35 mA.

In rder t maintain the same degree f pr tecti n as the AC units,

always use a Safety Agency Appr val DC s urce with the same

Overv ltage Categ ry and P lluti n Degree.

DC Powered Unit Connections

Connect the Sensor

1. L cate the TB2 c nnect r n the rear f the unit.

2. Attach the sens r wires and tighten the l ckd wn screws.

The diagram bel w sh ws the wiring f r bridge sens rs with internal

excitati n.

Refer t the Operat r’s Manual f r setup requirements f r ther

sens r types.

Bridge Sensor with Internal Excitation

3. Tug gently n the wires t verify the c nnecti ns.

4. Replace the panel at the back f the unit.

Using the Configuration Menu

T c nfigure the meter, y u use the butt ns n the fr nt panel.

To: Take This Action:

Display the Press the MENU butt n. The first functi n

C nfigurati n Menu n the menu, INPT, displays.

Select a submenu 1. Press MENU until the functi n y u

functi n want is sh wn.

2. Press /TARE.

The inf rmati n y u can change flashes.

Select a value 1. Press /NT/GRS t display the pti n

f r that submenu y u want.

functi n 2. Press MENU t st re it.

STRD quickly flashes, indicating that

the selecti n has been st red in mem ry.

Then the next menu functi n displays.

G back t previ us Press RESET nce.

menu functi n

Exit the Press RESET twice. The unit displays

C nfigurati n RST as it reinitializes. When a numeric

Menu value displays, the unit is in run m de.

(Opti nally, y u can press MENU t

m ve thr ugh all the menu functi ns

until the unit reinitializes.)

2 3 4

To Set the Decimal Point (continued

3.

Press /NT/GRS t m ve the decimal p int t

the desired l cati n. The fact ry settings is

FFFF. The ther ch ices are F.FFF, FF.FF,

and FFF.F.

4. Press MENU t select the decimal p int p siti n sh wn. The

unit displays:

To Scale the Meter

Y u can scale the meter in ne f tw ways:

1. With a kn wn l ad — This meth d uses input (l ad) inf rmati n

sent fr m an ther device such as a scale r a simulat r f r

v ltage r current.

2. With ut a kn wn l ad — This inv lves calculating the l ad

based n transducer specificati ns and manually entering it t

the meter.

F r b th meth ds, y u must first identify the minimum input l ad

IN!1 and the c rresp nding display reading y u want RD!1 . Then

y u identify the maximum input l ad IN!2 and its c rresp nding

display reading RD!2 .

The decimal p int is f r display purp ses nly — y u set it

where y u want it t display f r y ur applicati n.

When entering IN!1 and IN!2 values, ign re any decimal

p int n the display. H wever, y u must enter RD!1 and

RD!2 values with the decimal p int in the desired p siti n.

Scaling With Known Loads

T identify the minimum kn wn l ad (IN!1 and RD!1 ):

1. If it's n t already sh wn, press MENU until the unit displays:

2. Apply the minimum kn wn l ad (0%).

3. Press /TARE. The unit displays:

4. Press /TARE again. The unit displays the last setting f r

IN!1

.

5. Press /TARE again. The unit displays the actual reading

being received fr m the sending device.

MENU SUBMENU /TARE DESCRIPTION

INPT 100M, ±50M, !1 0V , !±5V , 0-20*Input

DEC.P FFFF *, F.FFF, FF.FF , FFF.F Decimal P int

RD.S.O IN!1, RD!1 , IN!2 , RD!2 Scale and Offset

RD.CF R.1=T *, R.1=N

Reading C nfigurati n

R.2=0, R.2=1, R.2=2, R.2=3, R.2=4

*

R.3=F*, R.3=U

R.4=P, R.4=G

COLR GRN, RED, AMBR Display C l r

S1.CF S.1=A *, S.1=B

Setp int 1 C nfigurati n

S.2=U*, S.2=L

S.3=N*, S.3=G

sh wn if R.4=G

S2.CF S.1=A *, S.1=B

Setp int 2 C nfigurati n

S.2=U*, S.2=L

S.3=N*, S.3=G

sh wn if R.4=G

S1.DB 0003 *

Setp int 1, Deadband

S2.DB 0003 *

Setp int 2, Deadband

OT.CF O.1=E *, 0.1=D Anal g Output

O.2=C *, 0.2=V

C nfigurati n

O.3=A *, 0.3=P

OT.S.O RD!1, OUT1, RD!2 , OUT2

Output Scale & Offset

LK.CF RS=E *, RS=D

L ck ut C nfigurati n

SP=E *, SP=D

L3=0*, L3=1

BRIT M.B T, .B T, H.B T

Display Brightness

* Fact ry Default Settings

To Set the Input Type

1. Press MENU until the unit displays:

2. Press /TARE. The unit displays:

3. F r this applicati n y u want 100M. If 100M is n t displayed,

press /NT/GRS until it appears. Other ch ices are 50M, 10V,

5V and 0-20.

Refer to the Operator's Man al for more information on

changing ranges.

4. Press MENU t select the sens r sh wn. The meter displays the

next menu item. If y u changed input type, the meter displays:

To Set the Decimal Point

1. If it's n t already sh wn, press MENU until the

unit displays:

2. Press /TARE. The unit displays:

Using the Configuration Menu (continued