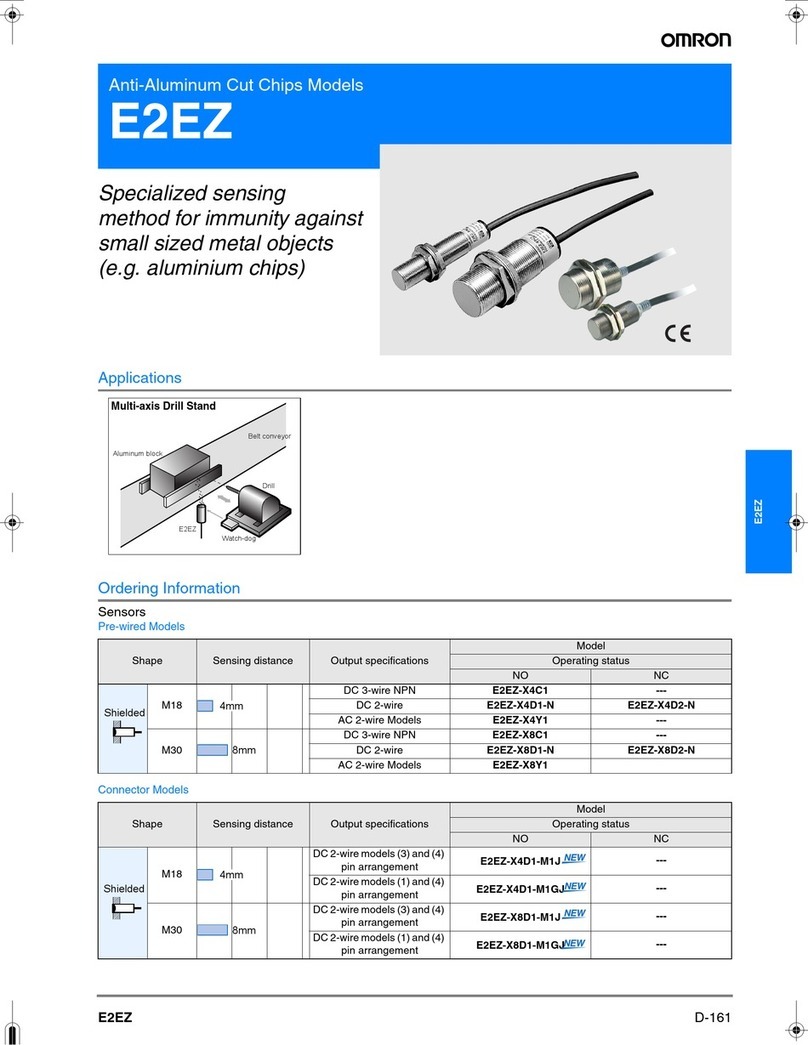

A-457E3C-LDA Series

E3C-LDA Series

Amplifier Units

*1: Communications are disabled if super-high-speed mode is selected, and the mutual interference prevention function and the communications

function for the Mobile Console will not function.

*2: The preset counter is available only with advanced, external-input models.

Nomenclature

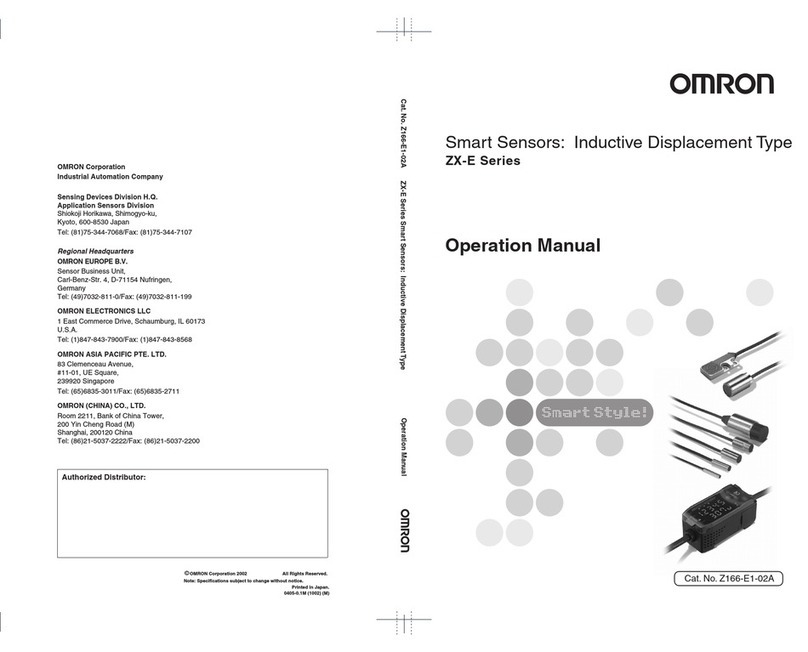

Type Advanced, twin-output models Advanced, external-input models

Model NPN output E3C-LDA11 E3C-LDA6 E3C-LDA21 E3C-LDA7

Item PNP output E3C-LDA41 E3C-LDA8 E3C-LDA51 E3C-LDA9

Supply voltage 12 to 24 VDC ±10%, ripple (p-p) 10% max.

Power consumption 1,080 mW max. (current consumption: 45 mA max. at power supply voltage of 24 VDC)

Control output Load power supply voltage: 26.4 VDC max.; NPN/PNP (depends on model) open collector

Load current: 50 mA max.; residual voltage: 1 V max.

Response

time

Super-high-speed mode 100 µs for operation and reset 80 µs for operation and reset

Standard mode 1 ms for operation and reset

High-resolution mode 4 ms for operation and reset

Functions

Power tuning, differential detection, timer, zero-reset, initial reset, mutual interference prevention (See note 1.), preset

counter (See note 2.), reversed display

I/O settings Output setting (Select from channel 2 output, area output, or

self-diagnosis.)

External input setting (Select from teaching, power tuning,

zero reset, light OFF, or counter reset.)

Display Operation indicator for channel 1 (orange), operation indica-

tor for channel 2 (orange) Operation indicator (orange), Power Tuning indicator (orange)

Digital display

Select from the following: Incident level + threshold, incident

level percentage + threshold, incident light peak level + no in-

cident light bottom level, minimum incident light peak level +

maximum no incident light bottom level, long bar display, in-

cident level + peak hold, incident level + channel

Select from same displays as given at the left or a counter dis-

play.

Ambient illumination

(receiver side)

Incandescent lamp:10,000 lux max.

Sunlight:20,000 lux max.

Ambient temperature

Operating:Groups of 1 to 2 Amplifiers: −25°C to 55°C

Groups of 3 to 11 Amplifiers: −25°C to 50°C

Groups of 12 to 16 Amplifiers: −25°C to 45°C

(with no icing or condensation)

Storage: −30°C to 70°C (with no icing or condensation)

Ambient humidity Operating and storage: 35% to 85% (with no condensation)

Connection method Prewired

cable Separate connector Prewired

cable Separate connector

Weight (packed state) Approx. 100 g Approx. 55 g Approx. 100 g Approx. 55 g

Materials Case Polybutylene terephthalate (PBT)

Cover Polycarbonate

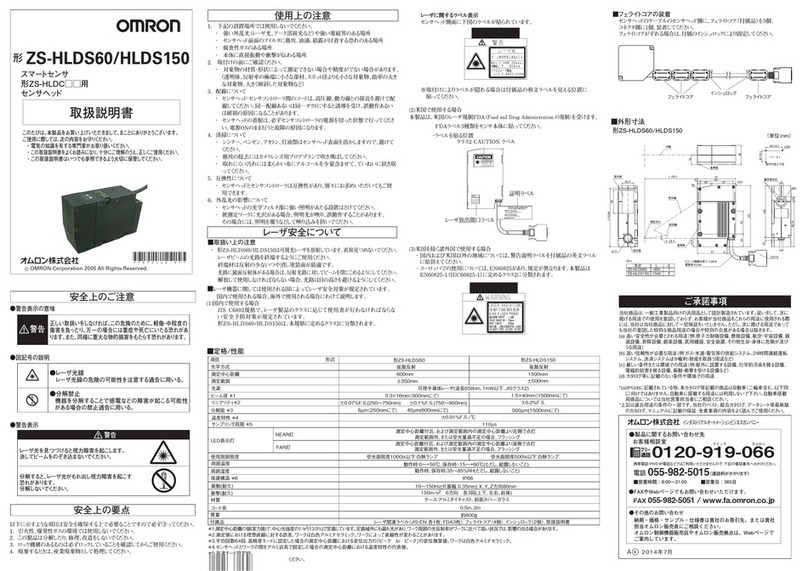

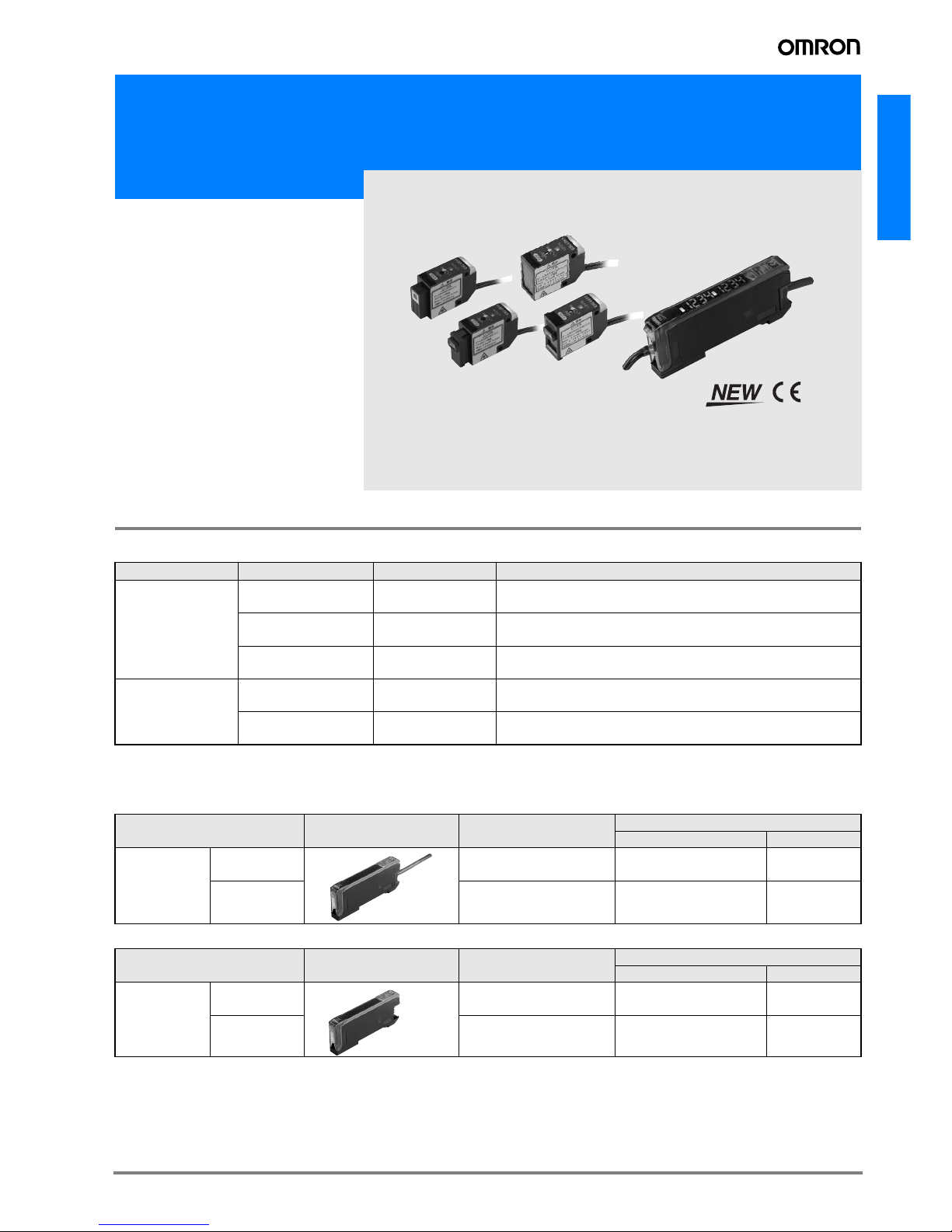

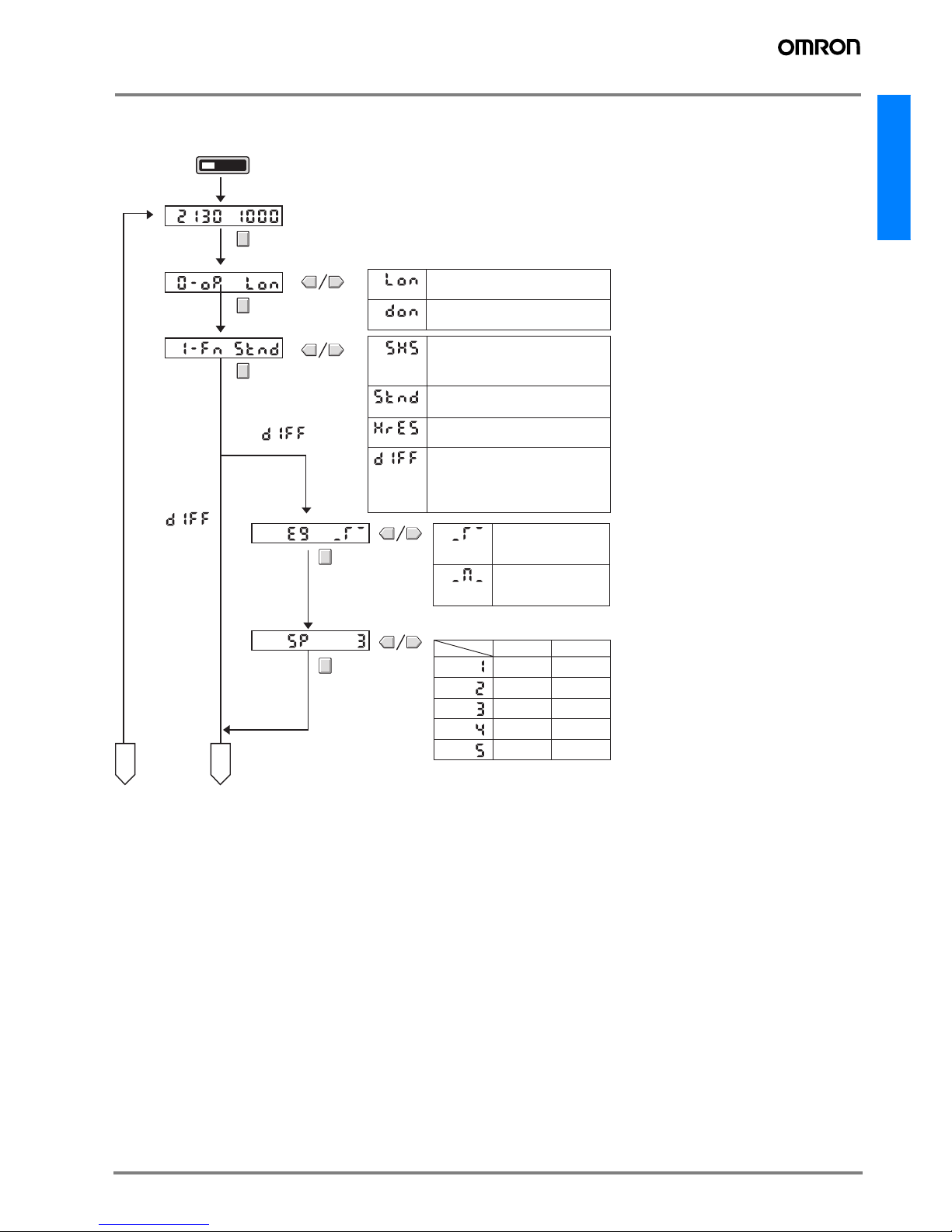

UP

SET RUN 12

DOWN MODE

LD

1 Operation indicator

2 Main display (red)

3 Twin-output Models: Operation indicator for channel 2

External-input Models: Power tuning indicator

4 Sub-display (green)

7 Operation keys

5 SET/RUN switch 6 Twin-output Models: Channel selector

External-input Models: Operation mode selector

Lit when the output is ON.

Twin-output Models: Lit when the output for channel 1 is ON.

2Displays the incident light level or the function name.

3Twin-output Models: Lit when the output for channel 2 is ON.

External-input Models: Lit when power tuning is set.

4Displays supplemental detection information, the setting of a function, etc.

5 Used to switch the mode.

6 Twin-output Models: Used to select the channel to display or set.

External-input Models: Used to select dark-ON or light-ON operation

7 Used to change the display, set functions, etc.

11