8

INTRODUCTION

Editor's Note

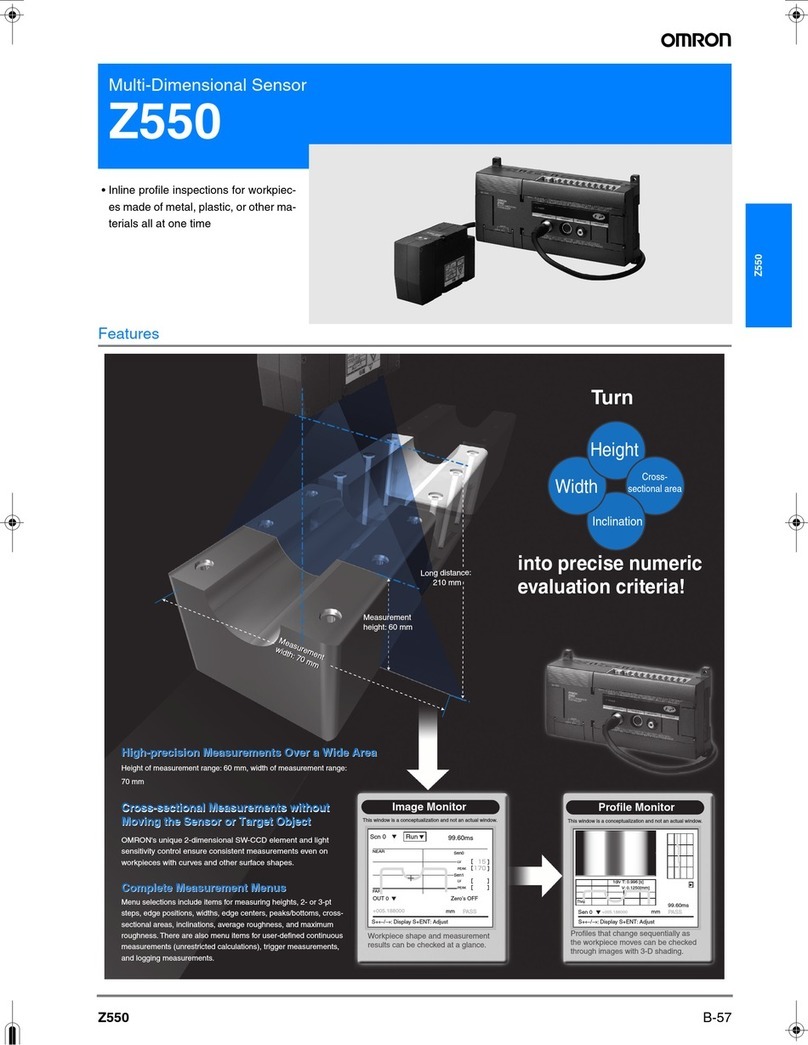

Z550

Operation Manual

INTRODUCTION

Editor's Note

Page Format

step7䊁䉴䊃䈜䉎/⸘䉕㐿ᆎ䈜䉎

⸳ቯ䈚䈢᧦ઙ䈪ᱜ䈚䈒⸘䈪䈐䉎䈎䉕䊁䉴䊃䈜䉎䇸⏕䊝䊷䊄䇹䈫䇮ታ㓙䈮⸘䉕㐿ᆎ䈜

䉎䇸⸘䊝䊷䊄䇹䈮䈧䈇䈩⺑䈚䉁䈜䇯

⸳ቯ䈚䈢᧦ઙ䈪ᱜ䈚䈒⸘䈪䈐䉎䈎䉕䊁䉴䊃䈚䉁䈚䉊䈉䇯

╙2┨䇭ၮᧄᠲ

⸳ቯ䊝䊷䊄䉕ᛮ䈔䈩䇮⥄േ⊛䈮⏕䊝䊷䊄䈮䉍䉁䈜

⸘‛䈏⊕↹⚛䈮䈭䉎䉋䈉䈮㒢୯䇮㒢୯

䉕⸳ቯ䈚䈩䈒䈣䈘䈇

ᄖធ㐳ᣇᒻ䈫䈲

63

㪪㫐㫊㫋㪼㫄㩷㪪㪼㫋㫋㫀㫅㪾㫊

Setting Measurement Items

Up to eight measurement items can be set for each scene.

The measurement items that have been set for the outputs can be changed.

Changing Measurement Items

Clear any previously set measurement items in order to assign other measurement

items.

p.117

SECTION 3

Setting Measurement Conditions (Expert Menu)

Move the cursor to the output whose item is

to be changed, and press the ENT key.

1.

Select [Change].2.

The options will be displayed.

The setting screen for measurement range

appears.

The remaining procedures are the same as

those for measurement item setting.

Operation Manual 31

Step 1

Sensor Installation Condition

Step 3

Measurement region setting

Step 4

Sensitivity adjustment

Step 5

Detection method

Step 6

Measurement setting

Step 2

Measurement method selection

SECTION 3

䃂Title of each section

䃂Header

Indicates the contents of the pag

䃂Sub-header

䃂Overview

Describes the overview and

operation flow of the section.

䃂Screen display

Indicates the status of the screen displayed on the left side.

䃂Index label

Indicates to which section the

current page belongs and

the contents of the page.

This allows the user to find

the target page quickly.

䃂Operation procedure and supplementary explanation

Helpful information regarding operation and reference pages is

introduced here using symbols.

䃂Overview and points of

the function described

⸳ቯ

* This page does not exist.

Operation Manual

Scn 0䂯䇭Set䂯

OUT0:Height

OUT1:Step: 2 pts

OUT2:

OUT3:

OUT4:

OUT5:

OUT6:

OUT7:

Scn 0䂯䇭Set䂯

Change

Calibrate

Output

Delete

SECTION 5

operation.bookPage8Monday,June6,200510:19AM