E3X-DA-N E3X-DA-N

3

Specifications

JAMPLIFIER RATINGS/CHARACTERISTICS

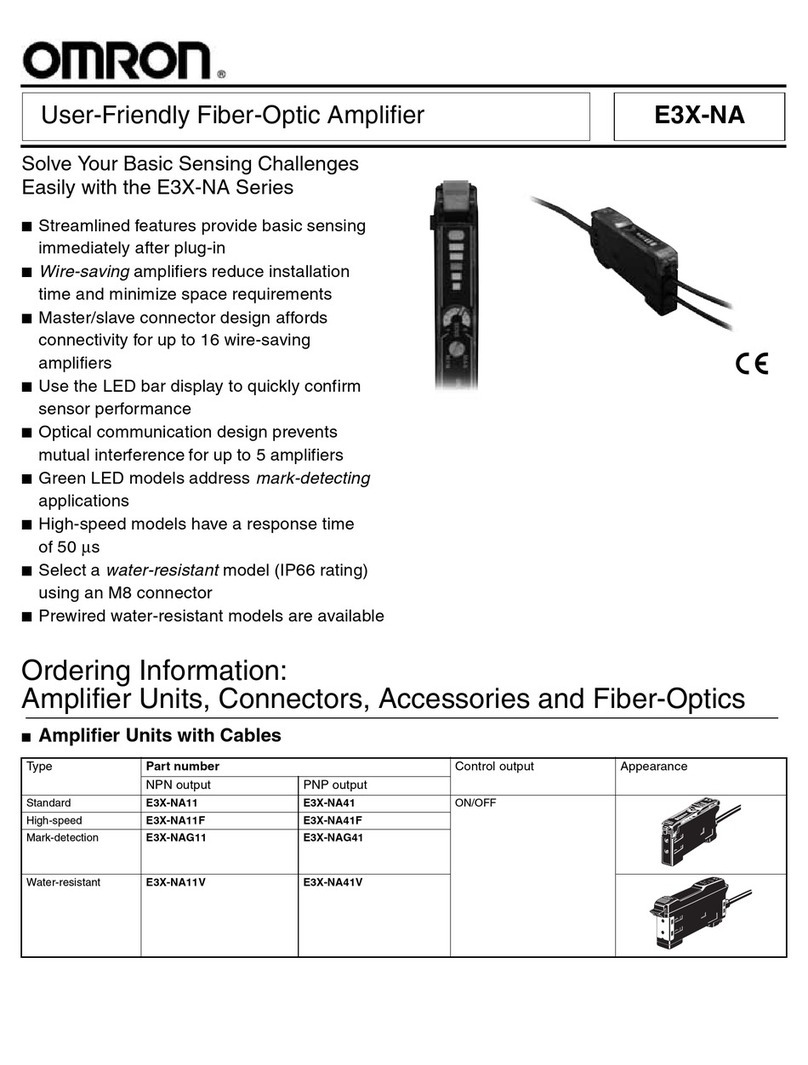

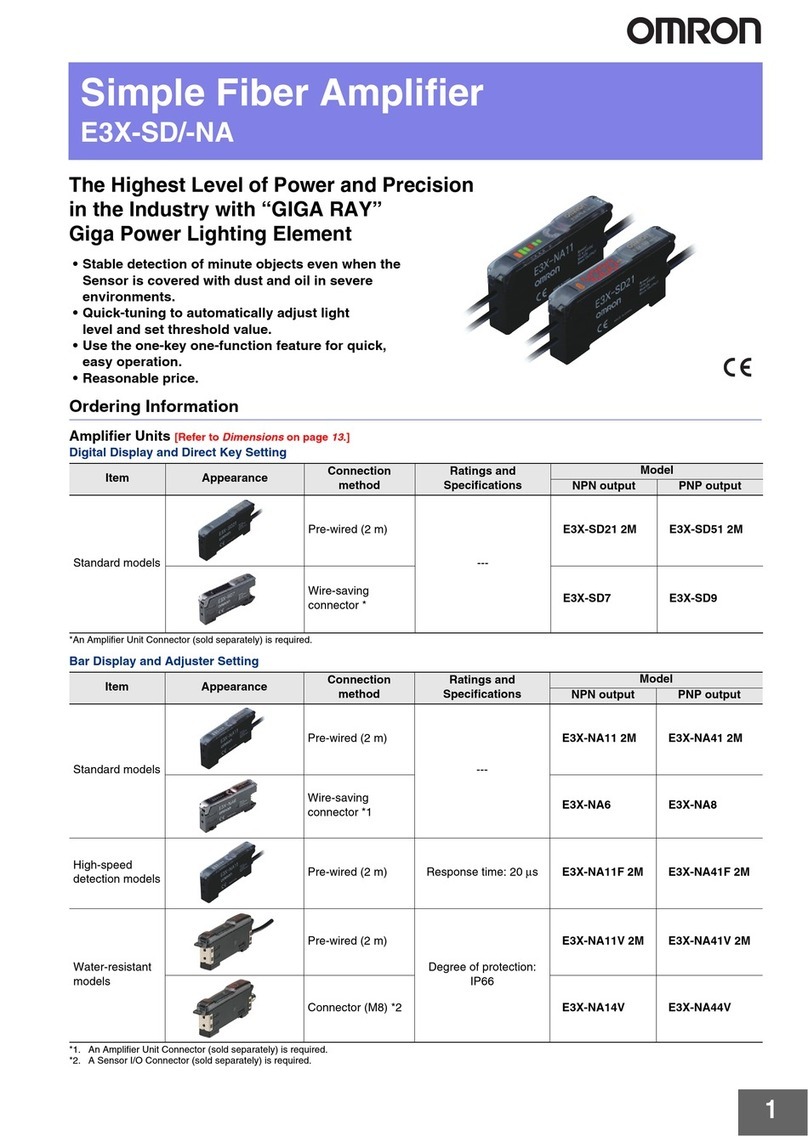

Description Digital output Analog/digital output Mark-detection M8 connector,

Prewired Connector Prewired Connector Prewired digital output

Output type NPN output E3X-DA11-N E3X-DA6 E3X-DA21-N E3X-DA7 E3X-DAB11-N E3X-DA14V

PNP output E3X-DA41-N E3X-DA8 E3X-DA51-N E3X-DA9 --- E3X-DA44V

Light source (wavelength) Red LED (660 nm) Blue LED

(470 nm) Red LED (660 nm)

Power supply voltage 12 to 24 VDC ±10%, ripple (p-p) 10% max.

Power Normal 960 mW max. (current consumption: 40 mA max. at power supply voltage of 24 VDC)

consumption Economy mode 720 mW max. (current consumption: 30 mA max. at power supply voltage of 24 VDC)

Digital display

not lit 600 mW max. (current consumption: 25 mA max. at power supply voltage of 24 VDC)

Control output ON/OFF output NPN/PNP (depends on model) open collector; load cur-

rent: 50 mA max.; residual voltage: 1 V max. NPN open col-

lector; load cur-

rent: 50 mA

max.; residual

voltage: 1 V

max.

NPN/PNP

(depends on

model) open col-

lector; load current:

50 mA max.; resid-

ual voltage: 1 V

max.

Analog output --- Load 1 to 5 VDC,

10 kΩmin. --- ---

Operation

mode Switch

selectable Light-ON/Dark-ON operation

Circuit protection Reverse polarity, output short-circuit, mutual interference prevention

Response time High-speed 250 µs for operation and reset respectively

by mode Standard 1 ms for operation and reset respectively

Long distance 4 ms for operation and reset respectively

Sensitivity setting Teaching or manual method

Functions Timer function OFF-delay timer range: 0 to 20 ms (set in 1 ms increments); 20 to 200 ms (set in 5 ms increments)

Automatic

power control

(APC)

Fiber-optic current digital control --- Fiber-optic current

digital control

Zero-reset Display can be reset to zero when required (negative values can be displayed).

Initial reset Settings can be returned to defaults as required.

Monitor focus --- Upper and lower limits can

be set as required for every

100 digital values.

--- ---

Display Function (color) Operation indicator (orange), 7-segment digital incident level display (red), 7-segment digital inci-

dent level percentage display (red), threshold and excess gain 2-color indication bar (green and

red), 7-segment digital threshold display (red)

Timing Normal/peak-hold/bottom-hold, program selectable

Orientation Normal/reverse, program selectable

Optical axis adjustment Optical axis adjustment possible (flashing function)

Ambient illumination Illumination intensity at light-intercepting surface:

Incandescent lamp: 10,000 lx max.; Sunlight: 20,000 lx max.

Ambient

temperature Operating Groups of 1 to 3 Amplifiers: –25°C to 55°C (–13°F to 131°F)

Groups of 4 to11 Amplifiers: –25°C to 50°C (–13°F to 122°F)

Groups of 12 to16 Amplifiers: –25°C to 45°C (–13°F to 113°F)

with no icing or condensation

Storage –30°C to 70°C (–22°F to 158°F) with no icing or condensation

Ambient humidity Operating and storage: 35% to 85% with no condensation

Insulation resistance 20 MΩmin. at 500 VDC

Dielectric strength 1,000 VAC at 50/60 Hz for 1 minute

Vibration resistance 10 to 55 Hz with a 1.5-mm double amplitude for 2 hrs each in X, Y and Z directions

(This table continues on the next page.)