vii

TABLE OF CONTENTS

PRECAUTIONS .........................................................................................xi

1 Intended Audience........................................................................................................................................................xii

2 General Precautions......................................................................................................................................................xii

3 Safety Precautions ........................................................................................................................................................xii

4 Operating Environment Precautions.............................................................................................................................xii

5 Application Precautions...............................................................................................................................................xiii

6 EC Directives ..............................................................................................................................................................xiv

1 PROFIBUS-DP...................................................................................... 1

1-1 Introduction..............................................................................................................................................................2

1-2 Protocol architecture ................................................................................................................................................2

1-3 Device types.............................................................................................................................................................4

1-4 PROFIBUS-DP characteristics.................................................................................................................................4

1-5 Device Data Base files .............................................................................................................................................8

1-6 Profiles.....................................................................................................................................................................8

2 INSTALLATION.................................................................................. 9

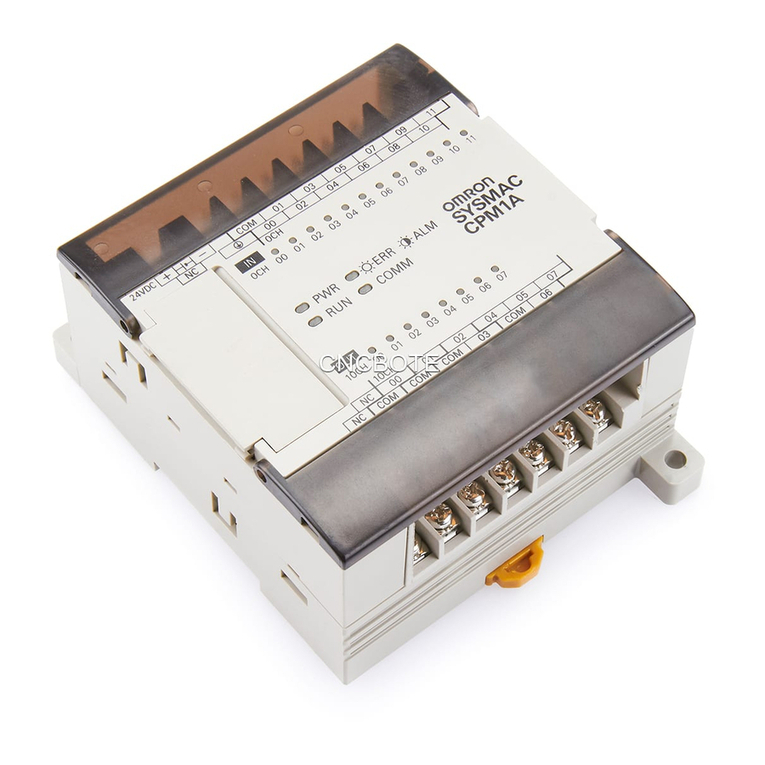

2-1 Physical layout of the unit......................................................................................................................................10

2-2 Mounting the C200HW-PRM21 ............................................................................................................................13

2-3 Setting up a network...............................................................................................................................................14

3 SPECIFICATIONS AND PERFORMANCE..................................17

3-1 Overall Specifications............................................................................................................................................18

3-2 Performance ...........................................................................................................................................................20

4 CONFIGURATOR.............................................................................29

4-1 General...................................................................................................................................................................30

4-2 Setup ......................................................................................................................................................................31

4-3 Operation................................................................................................................................................................32

4-4 Debug mode...........................................................................................................................................................46

5 PLC INTERFACE..............................................................................51

5-1 Unit Settings...........................................................................................................................................................52

5-2 Input / Output Mailbox...........................................................................................................................................59

5-3 Control and status area...........................................................................................................................................60

5-4 LEDs ......................................................................................................................................................................70

6 MESSAGE COMMUNICATION, IOWR / IORD .........................73

6-1 Message communication........................................................................................................................................74

6-2 IOWR.....................................................................................................................................................................74

6-3 IORD......................................................................................................................................................................76

6-4 Messages................................................................................................................................................................77

7 TROUBLESHOOTING AND MAINTENANCE ...........................83

7-1 Error Indicators......................................................................................................................................................84

7-2 Troubleshooting .....................................................................................................................................................84

7-3 Maintenance...........................................................................................................................................................90