●Power Supply and Wiring

Make sure to use the product with the power supply voltage

specified by this manual.

Use the specified wire size (AWG10 to 16).

Keep the power supply wires as short as possible (Max.2m).

Use a DC power supply with safety measures against high-voltage

spikes(safety extra low-voltage circuits on the secondary side).

'RWKHIROORZLQJFRQILUPDWLRQVDJDLQEHIRUHWXUQLQJRQWKHSRZHU

supply.

- Is the voltage and polarity of the power supply correct? (24VDC)

- Is not the load of the output signal short-circuited?

- Is the load current of the output signal appropriate?

- Is not the mistake found in wiring?

- Is the voltage and polarity of the encoder power(ENC0 VDD /

ENC0 GND / ENC1 VDD / ENC1 GND) supply ? (5VDC)

●Ground

The power supply circuit of the FH Sensor Controller is insulated

from the internal circuit.

Be sure to use a base to install the camera connected with the FH

Sensor Controller. Since the exclosure of the camera main body

made of metals is short-circuited with the internal circuit, the

internal circuit might be short-circuited with FG if no base is used,

so that failures or malfunctions may be caused.

3HUIRUP&ODVV'JURXQGLQJZLWKDJURXQGLQJUHVLVWDQFHRIїor

less).

Keep the ground line as short as possible by setting the grounding

point as close as possible.

Ground the FH Sensor Controller independently. If sharing the

ground line with other devices or connecting it with a building

beam, the Sensor Controller might be adversely effected.

Check wiring again before turning on the FH Sensor Controller.

'RQRWJURXQGWKHSOXVWHUPLQDORIWKH9'&SRZHUVRXUFH

when the FH Sensor Controllers are connected to the

FH-SC12/FH-SM12 (12 megapixels).

Doing so may cause a short circuit of the internal circuit,

resulting in a malfunction.

'RQRWJURXQGWKHSOXVWHUPLQDORIWKH9'&SRZHUVRXUFH

when the FH Sensor Controllers are connected to the FH-MT12

with a USB cable. Doing so may cause a short circuit of the

internal circuit, resulting in a malfunction.

●Other

Use only the camera and cables designed specifically for the

product. Use of other products may result in malfunction or damage

of the product.

・Please insert DVI-I connector perpendicularly so that the connector

resin part and pin are not rubbing against each other. Damaged pin

may cause contact failure due to generation and invasion of resin

powder.

Always turn OFF the power of the FH Sensor Controller and

peripheral devices before connecting or disconnecting a camera or

cable. Connecting the cable with power supplied may result in

damage of the camera or peripheral devices.

For the cable that is flexed repeatedly, use the robotic cable type

(Bend resistant camera cable) to prevent damages.

Do not apply torsion stress to the cable. It may damage the cable.

Secure the minimum bending radius of the cable. Otherwise the

cable may be damaged.

Do not attempt to dismantle, repair, or modify the product.

Should you notice any abnormalities, immediately stop use, turn

OFF the power supply, and contact your OMRON representative.

The FH Sensor Controller and camera case are hot while power is

supplied or directly after the FH Sensor Controller is turned off. Do

not touch the case.

Be sure to dispose of the product as industrial waste.

Do not drop, impose excessive vibration or shock on the product.

Doing so may result in malfunction or burning.

Since a lithium battery is incorporated, there is a rare case when

you are seriously injured due to firing or blowout.

・Fail-safe measures, external to this system, should be in place to

ensure safety when using Sensor Controller measurement results

to control the movement of a robot and conveyor, or stage.

●Regulations of KC marking

˙ૺૺˀ࿕ඳဧ෮ቛཅૺၴႁˁ

ၦૺૺ௴࿕ඳဧ˙႖ၴኒ႕ጁૺૺചን൯ၴ

ವ௴ຫဧၴ௴ၦ႙ၕၡዻགྷૺೡඑႜဘၡ

ხຫဧዻ௴ઇၕඛ႕ၒചጁఁఋ

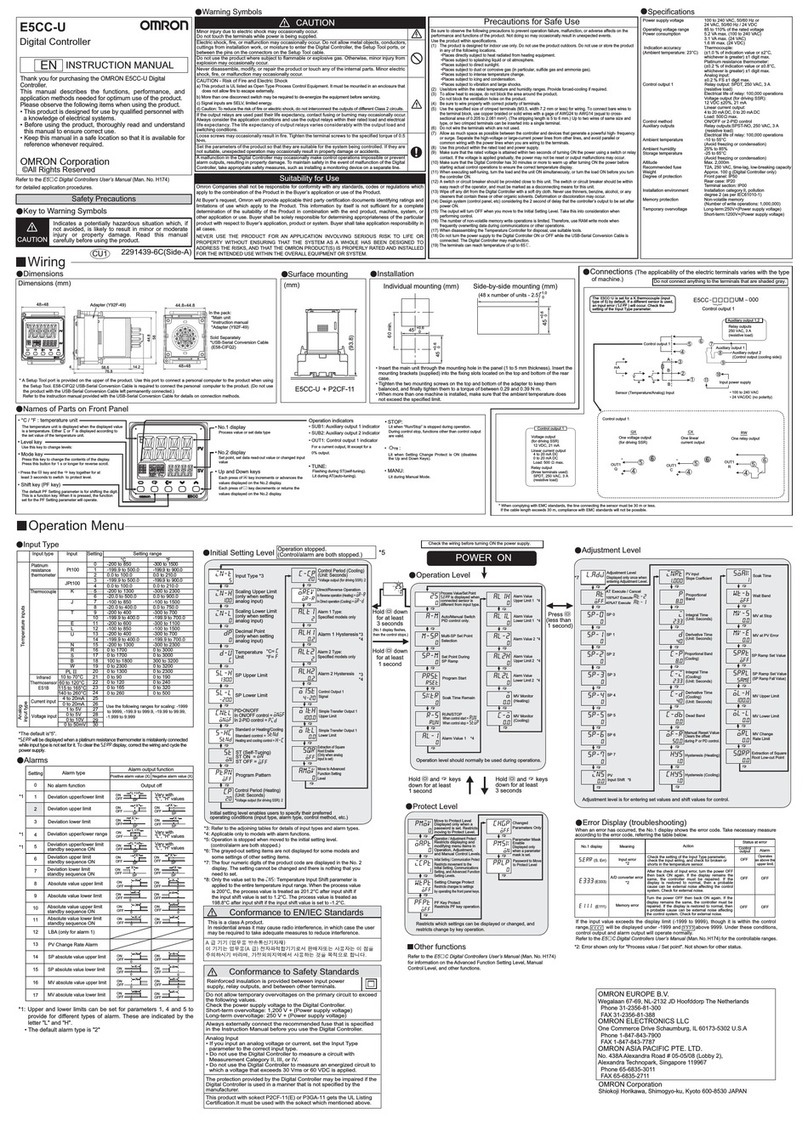

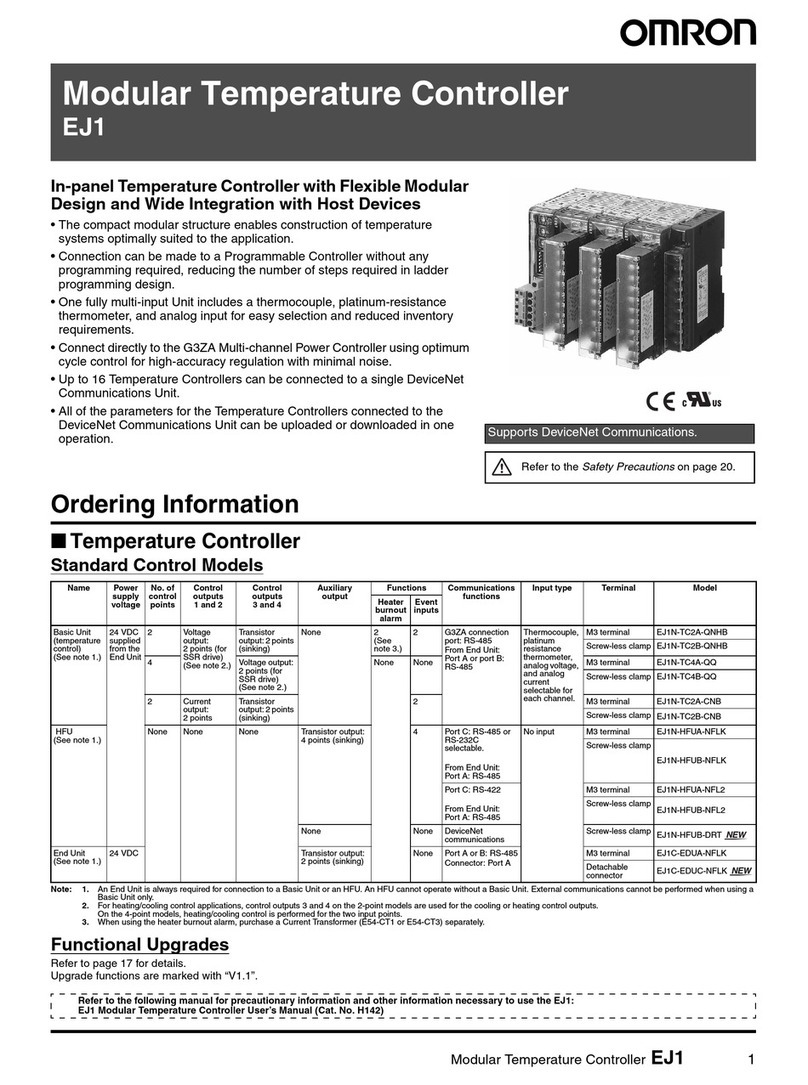

Image Processing System

FH-1050

FH-3050

FH-1050-0

FH-3050-0

■Basic Configuration

*Items indicated with an asterisk are dedicated items, and cannot be substituted.

**

Do not install in this orientation.

FFH-VMDA

(2m, 5m, 10m, min. bending radius 36mm)

FH-VMDA(2m,5m,10m,min. bending radius 36mm)

A

B

C

D

E

F

G

H

I

K

L

●Ambient Temperature

To keep proper air flow, keep the top of the FH Sensor Controller

50mm or more apart from other devices. Install the FH Sensor

Controller with a clearance of 30mm on the right and left side, and

15mm for rear planes. The clearance is required for installing

multiple units side-by-side.

Clearance is not required for the side mounting.

Do not install the product immediately above significant heat

sources, such as heaters, transformers, or large-capacity resistors.

Do not let the ambient temperature exceed 50℃(122°F).

Provide a forced-air fan cooling or air conditioning if the ambient

temperature is near 50℃(122°F) so that the

ambient temperature never exceeds 50℃(122°F).

●Noise Resistance

Do not install the product in a cabinet containing high-voltage

equipment.

Do not install the product within 200 mm of power cables.

●Component Installation and Handling

Touching Signal Lines

To prevent damage from static electricity, use a wrist strap or

another device for preventing electrostatic discharges when

touching terminals or signal lines in connectors.

Handling a USB Memory/SD memory card

To remove a USB memory or SD memory card, make sure that

data is not being read or written to it.

For USB memory, the LED flashes while data is being read or

written, so make sure that it is lit steadily before removing the

memory.

For SD memory card, the SD BUSY LED flashes while data is

being read or written, so make sure that it is turned OFF before

removing the memory.

When you insert the SD memory card, please do not insert in the

reverse, do not insert at an angle and do not insert while twisting.

Turning OFF the Power

Do not turn OFF the power while a message is being displayed

indicating that processing is being performed. Data in memory will

be corrupted, and the product may not operate correctly the next

time it is started.

●Maintenance

7XUQ2))WKHSRZHUDQGWDNHVDIHW\SUHFDXWLRQVEHIRUHconducting

inspections. Electrical shock can result from attempting safety

inspections with the power turned ON.

Clean the lens with a lens-cleaning cloth or air brush.

Lightly wipe off dirt with a soft cloth.

Dirt on the image element must be removed using an air brush.

Do not use thinners or benzene.

●Communication with High-order Device

After confirming that this product is started up, communicate with

the high-order device. When this product has started up, an

indefinite signal may be output from the high-order interface. To

avoid this problem, clear the receiving buffer of your device at initial

operations.

●Fail-Safe Measures

If you wish to operate a stage and/or a robot using a measurement

result from a FH Sensor Controller(e.g. axis movement amount

output based on calibration/alignment measurement),always take

safety measures so that the measurement result should be

checked by the stage/robot if it is within the range of movement of

the stage/robot before operation.

2QD)+6HQVRU&RQWUROOHUVLGHVXSSOHPHQWDULO\XVHRSHUDWLRQV

and branches of the FH Sensor Controller to configure a check

flow such as “data should not be externally provided if the data

is in a range from-XXXXX to XXXXX ”based on the stage/robot’s

range of movement.

●In case of connecting the sensor controller and monitor with a

switcher and splitter:

・Do not use devices that may require re-recognition of the

monitor by the sensor controller. Re-recognizing the monitor

during switch may slow the inspection speed down.

The power supply connected to FH Sensor

Controller varies depending on the number of

connected cameras and types for various

consumption current types. Use is accordingly.

J

INSTRUCTION SHEET

Thank you for selecting OMRON product. This sheet pri-

marily describes precautions required in installing and

operating the product.

Before operating the product, read the sheet thoroughly to

acquire sufficient knowledge of the product. For your con-

venience, keep the sheet at your disposal.

TRACEABILITY INFORMATION:

Importer in EU

Omron Europe B.V.

Wegalaan 67-69

2132 JD Hoofddorp,

The Netherlands

Manufacturer

Omron Corporation,

Shiokoji Horikawa, Shimogyo-ku,

Kyoto, 600-8530 JAPAN

2013-2015

Meanings of Signal Words

Meanings of Alert Symbols

Alert statements in this Manual

The following alert symbols are used in this manual.

The following alert statements apply to the products in this

manual. Each alert statement also appears at the locations

needed in this manual to attract your attention.

Indicates a potentially hazardous

situation which, if not avoided, will

result in minor or moderate injury, or

may result in serious injury or death.

Additionally there may be significant

property damage.

WARNING

Indicates a potentially hazardous

situation which, if not avoided, may

result in minor or moderate injury or in

property damage.

Indicates general prohibitions for which there is

no specific symbol.

Indicates the possibility of electric shock under

specific conditions.

Indicates the possibility of explosion under

specific conditions.

Indicates the possibility of laser radiation.

Indicates the possibility of injury by high

temperature under specific conditions.

CAUTION

●

Symbols and the meanings for safety precautions

described in this manual.

In order for the product to be used safely, the following

indications are used in this book to draw your attention to

the cautions. The cautions with the indications describe

the important contents for safety.

Precautions for Safe Use

WARNING

CAUTION

This product must be used according to the

instruction manual. Failure to observe this may

result in impairment of functions and

performance of the product.

This product is not designed or rated for

ensuring safety of persons. Do not use it for

such purposes.

Never connect the AC power supply with this

product. When the AC power supply is

connected, it causes the electric shock and a fire.

Do not touch the terminals while the power supply

is ON. Doing so may result in electrical shock.

A lithium battery is built into the Sensor Controller

and may occasionally combust, explode, or burn if

not treated properly. Dispose of the Sensor Controller

as industrial waste, and never disassemble, apply

pressure that would deform, heat to 100℃or higher,

or incinerate the Sensor Controller.

Since camera that can be connected with this

product emits a visible light that may have an

adverse effect on the eyes, do not stare directly

into the light emitted from the LED. If a specular

object is used, take care not to allow reflected

light enter your eyes.

Please take external safety measures so that the

system as a whole should be on the safe side

even if a failure of a Sensor Controlleror an error

due to an external factor occurred.An abnormal

operation may result in serious accident.

Please take fail-safe measures on your side in

preparation for an abnormal signal due to signal

conductor disconnection and/or momentary

power interruption.An abnormal operation may

result in a serious accident.

Danger of burns. Do not touch the case while the

LED is ON or just after power is turned OFF,

since it remains extremely hot.

●Installation Environment

Do not use the product in areas where flammable or explosive

gases are present.

Install the product so that air can flow freely through its cooling vents.

Clean the vent hole and discharge opening to prevent dust or

particles from blocking them. Blocked cooling vents or discharge

opening of the fan increasing heat inside, causing malfunction of

the product.

Do not install the product close to high-voltage devices and power

devices in order to secure the safety of operation and

maintenance.

Make sure to tighten all installation screws securely.

Precautions for Correct Use

●Installation and Storage Sites

Install and store the product in a location that meets the following

conditions:

Surrounding temperature of 0 to 50℃WR℃in storage)

No rapid changes in temperature (place where dew does not form)

Relative humidity of between 35 to 85 %

No presence of corrosive or flammable gases

Place free of dust, salts and iron particles

Place free of vibration and shock

Place out of direct sunlight

Place where it will not come into contact with water, oils or

chemicals

●Orientation of Product

To keep proper ventilation, install the main unit only in the

direction below so that the ventilation holes are not blocked.

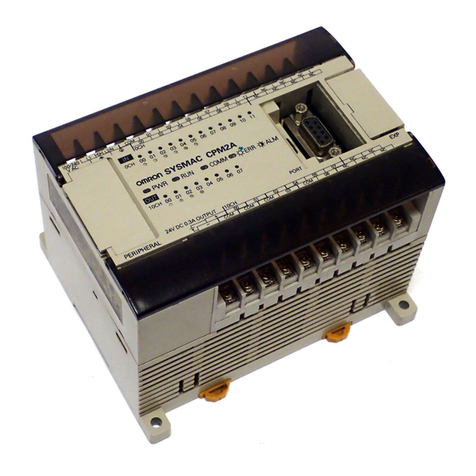

Sensor controller

The Sensor Controller performs the image processing

specified by the user settings and outputs the measurement

results. Camera 4ch type

FH-3050-10

FH-1050-10

Camera 8ch type

FH-3050-20

FH-1050-20

Camera 2ch type

FH-3050

FH-1050

LCD monitor

Use the monitor to check images and

display the condition-setting menus. Use the monitor to check images and

display the condition-setting menus.

FZ-M08(8.4inch)

Monitor cable Monitor cable

Camera cable

FZ-VS3(2m,3m,5m,10m,min.bending radius: 69mm)

Bend resistant Camera cable

FZ-VSB3(2m,3m,5m,10m,min.bending radius: 69mm)

Right-angle Camera cable

FZ-VSL3(2m,3m,5m,10m,min.bending radius: 69mm)

Bend resistant Right-angle Camera cabe

FZ-VSLB3(2m,3m,5m,10m,min.bending radius: 69mm)

Long-distance Camera cable

FZ-VS4(15m,min.bending radius: 78mm)

Long-distance Right-angle Camera cable

FZ-VSL4(15m,min.bending radius: 78mm)

Camera cable

Camera

Standalone camera

FZ-SC/FZ-S/

FZ-SC2M/FZ-S2M/

FZ-SFC/FZ-SF/

FZ-SPC/FZ-SP/

FZ-SHC/FZ-SH/

FH-SC/FH-SM/

FH-SC02/FH-SM02/

FH-SC04/FH-SM04/

FZ-SC5M2/FZ-S5M2/

FH-SC12/FH-SM12

Intelligent compact camera

FZ-SQ010F/FZ-SQ050F/

FZ-SQ100F/FZ-SQ100N

Detects workpieces as images.

Power Supply

Peripheral Device

Input Device

USB memory

FZ-MEM2G

FZ-MEM8G

SD memory card

HMC-SD291

HMC-SD491

Mouse, keyboard

(Commercially available

USB driverless wired devices)

Recommended Model by OMRON:

S8VS series

S8VS-09024, S8VS-12024

S8VS-18024,S8VS-24024

S8VS-48024

Connector name Description

SD memory card installation connector Install the SD memory card. Do not plug or unplug the SD memory card during measurement

operation. Otherwise measurement time may be affected or data may be destroyed.

Ethernet connector Connect an Ethernet device.

USB connector Connect a USB device. Do not plug or unplug it during measurement and accessing

USB device. Measurement time might be affected otherwise.

RS-232C connector Connect an external device such as a PLC.

Monitor connector Connect a monitor.

I/O(Parallel) connector(control lines, data lines)

Connect the controller to external devices such as a sync sensor and PLC.

EtherCAT address setup volume Used to set a station address ( 00 to 99) as an EtherCAT communication device.

EtherCAT communication connector (IN)

Connect the opposed EtherCAT device.

EtherCAT communication connector (OUT)

Connect the opposed EtherCAT device.

Camera connector Connect cameras.

Power supply terminal connector

Connect a DC power supply. Wire the FH Sensor Controller independently on other devices.

Wire the ground line. Be sure to ground the FH Sensor Controller alone. Perform wiring using

the attached terminal block connector (FH-XCN) as referring to the description of wiring that connector.

A

B

C

D

E

F

G

H

I

K

Encoder connector Connect an encoder.

J

L

■Component Names and Functions

LED name Description

POWERLED Lit while power is ON.

ERROR LED Lit when an error has occurred.

RUN LED Lit while the layout turned on output setting is displayed.

ACCESSLED Blinks while the internal nonvolatile memory is accessed.

SDPOWER LED Lit while power is supplied to the SD memory card and the card is usable.

SDBUSY LED Blinks while the SD memory card is accessed.

EtherCAT RUN LED Lit while EtherCAT communications are usable.

EtherCAT LINK/ACT IN LED Lit when connected with an EtherCAT device, and blinks while performing communications.

Lit when connected with an EtherCAT device, and blinks while performing communications.

EtherCAT LINK/ACT OUT LED

Lit when EtherCAT communications have become abnormal.

EtherCAT ERR LED

Lit when Ethernet communications are usable.

Ethernet NET RUN1 LED Lit while Ethernet communications are usable.

Ethernet NET LINK/ACK1 LED Lit when connected with an Ethernet device, and blinks while performing communications.

Ethernet NET RUN2 LED

Ethernet NET LINK/ACK2 LED Lit when connected with an Ethernet device, and blinks while performing communications.

*

*

*

*

*

*

Camera 2ch type Camera 4ch / 8ch type

Ethernet port and

EtherNet/IP port are

sharing use.

Upper port :

Ethernet port

Lower port :

Ethernet port and

EtherNet/IP port are

sharing use.

9607479-9B Touch panel monitor

FH-MT12(12.1inch)

FH-VUAB

(USB type,2m,5m,min.bending radius: 25mm)

XW2Z-□□□PP-1

(RS-232Ctype,2m,5m,10m min.bending radius: 59mm)

Touch panel cable

*

*

*

Switcher

In case of switching multiple of sensor

controllers with a single monitor or

touch panel monitor, please make sure

to use an appropriate product.

Recommended model

by OMRON: FZ-DU