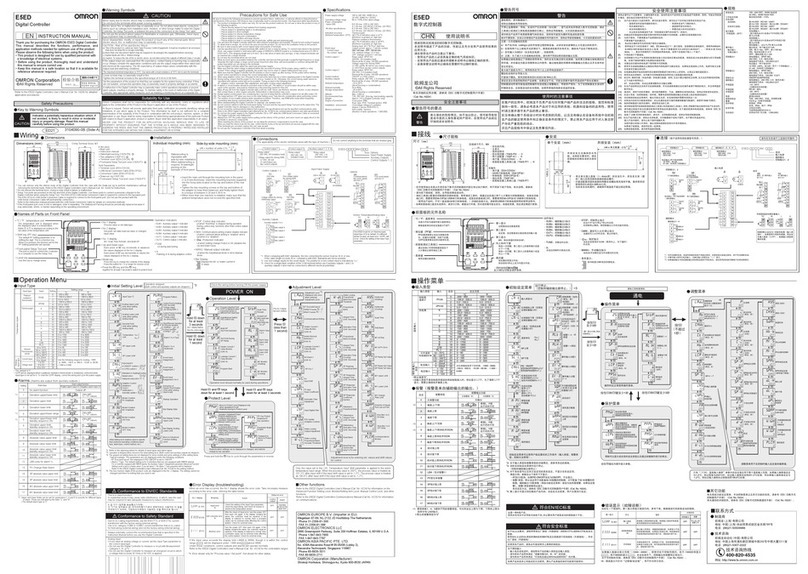

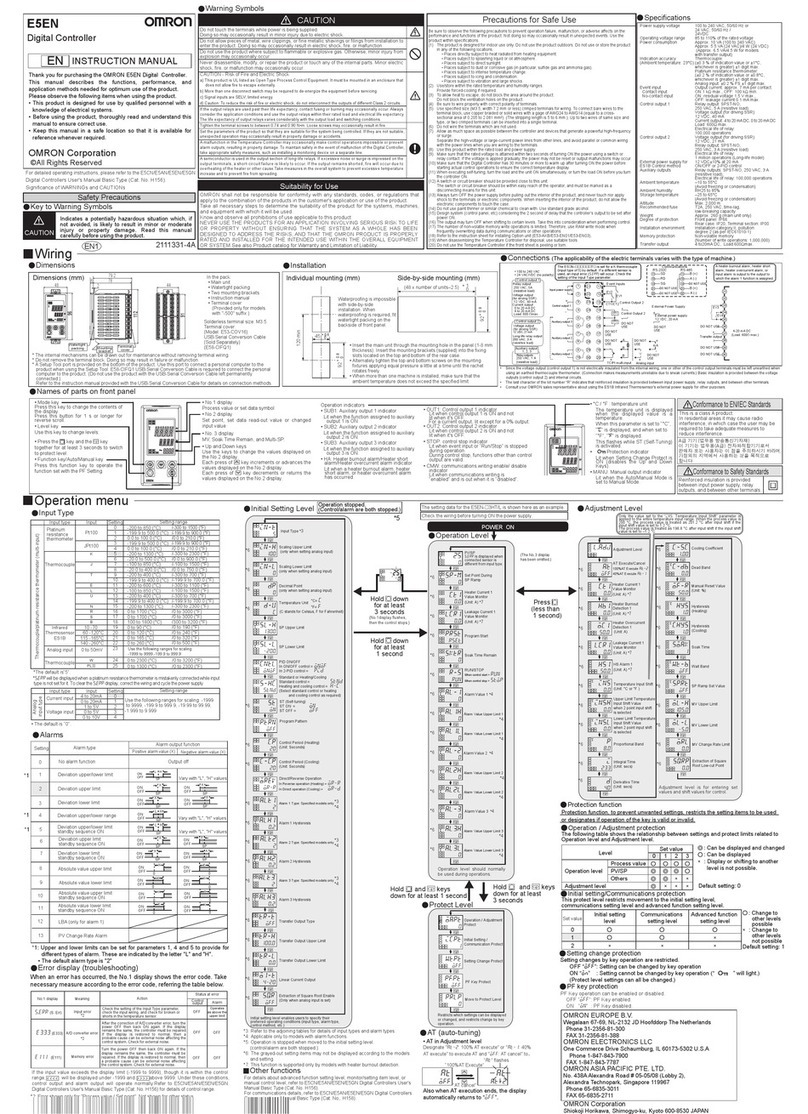

E5AK

V

FIf you remove the controller from its case, never touch nor apply shock to the elec-

tronic parts inside.

FDo not cover the area around the E5AK. (Ensure sufficient space around the control-

ler to allow heat radiation.)

FUse a voltage (AC100-240V or AC/DC24V at 50 to 60 Hz). At power ON, the pre-

scribed voltage level must be attained within two seconds.

FWhen wiring input or output lines to your controller, keep the following points in

mind to reduce the influence from inductive noise:

•Allow adequate space between the high voltage/current power lines and the input/

output lines.

•Avoid parallel or common wiring with high voltage sources and power lines carrying

large currents.

•Using separating pipes, duct, and shielded line is also useful in protecting the con-

troller, and its lines form inductive noise.

FAllow as much space as possible between the controller and devices that generate a

powerful, high frequency (high-frequency welders, high-frequency sewing machines,

and so forth) or surge. These devices may cause malfunctions.

FIf there is a large power-generating peripheral device and any of its lines, attach a

surge suppressor or noise filter to the device to stop the noise affecting the controller

system. In particular, motors, transformers, solenoids and magnetic coils have an

inductance component, and therefore can generate very strong noises.

FWhen mounting a noise filter, be sure to first check the filter’s voltage and current

capacity, then mount the filter as close as possible to the controller.

FDo not use the controller in places where icing, condensation, dust, corrosive gas

(especially sulfurized gas or ammonia gas), shock, vibration, splashing liquid, or oil

atmosphere occur. Also, avoid places where the controller can be subjected to intense

heat radiation (like from a furnace) or sudden temperature changes.

FAmbient temperature must be kept between -10_Cto55_C. Ambient humidity must

be kept between 35%RH to 85%RH (with no icing or condensation). If the controller

is installed inside a control board, the ambient temperature must be kept under

55_C, including the temperature around the controller. If the controller is subjected

to heat radiation, use a fan to cool the surface of the controller to under 55_C.

FStore the controller at an ambient temperature between -25_Cto65_C. The ambient

humidity must be between 35%RH to 85%RH (with no icing or condensation).

FNever place heavy objects on, or apply pressure to the controller that may cause it to

deform and deterioration during use or storage.

FAvoid using the controller in places near a radio, television set, or wireless installa-

tion. These devices can cause radio disturbances which adversely affect the perfor-

mance of the controller.

Pay

ttention to the Following when Installing

this Controller