5Application Precautions

x

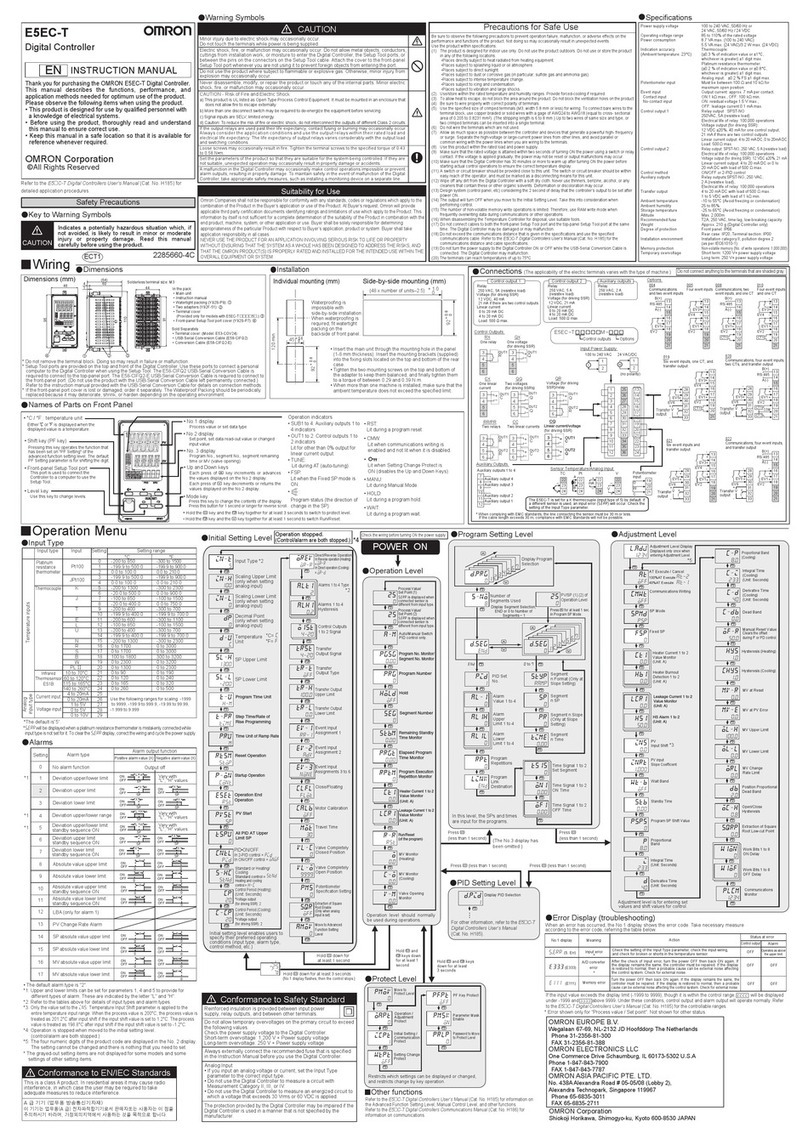

•Interlock circuits, limit circuits, and similar safety measures in external circuits

(i.e., not in the Programmable Controller) must be provided by the customer.

•Always use the power supply voltages specified in this manual. An incorrect

voltage may result in malfunction or burning.

•Take appropriate measures to ensure that the specified power with the rated

voltage and frequency is supplied. Be particularly careful in places where the

power supply is unstable. An incorrect power supply may result in malfunction.

•Install external breakers and take other safety measures against short-circuit-

ing in external wiring. Insufficient safety measures against short-circuiting may

result in burning.

•Do not apply voltages to the Input Units in excess of the rated input voltage.

Excess voltages may result in burning.

•Do not apply voltages or connect loads to the Output Units in excess of the

maximum switching capacity. Excess voltage or loads may result in burning.

•Disconnect the functional ground terminal when performing withstand voltage

tests. Not disconnecting the functional ground terminal may result in burning.

•Be sure that all the mounting screws, terminal screws, and cable connector

screws are tightened to the torque specified in this manual. Incorrect tighten-

ing torque may result in malfunction.

•Leave the label attached to the Unit when wiring. Removing the label may re-

sult in malfunction if foreign matter enters the Unit.

•Remove the label after the completion of wiring to ensure proper heat dissipa-

tion. Leaving the label attached may result in malfunction.

•Double-check all wiring and switch settings before turning ON the power sup-

ply. Incorrect wiring may result in burning.

•Wire correctly. Incorrect wiring may result in burning.

•Mount Units only after checking terminal blocks and connectors completely.

•Be sure that the terminal blocks, Memory Units, expansion cables, and other

items with locking devices are properly locked into place. Improper locking

may result in malfunction.

•Check the user program for proper execution before actually running it on the

Unit. Not checking the program may result in an unexpected operation.

•Confirm that no adverse effect will occur in the system before attempting any of

the following. Not doing so may result in an unexpected operation.

•Changing the operating mode of the PC.

•Force-setting/force-resetting any bit in memory.

•Changing the present value of any word or any set value in memory.

•Resume operation only after transferring to the new CPU Unit the contents of

the DM Area, HR Area, and other data required for resuming operation. Not

doing so may result in an unexpected operation.

•Do not pull on the cables or bend the cables beyond their natural limit. Doing

either of these may break the cables.

•Do not place objects on top of the cables or other wiring lines. Doing so may

break the cables.

•Use crimp terminals for wiring. Do not connect bare stranded wires directly to

terminals. Connection of bare stranded wires may result in burning.

•When replacing parts, be sure to confirm that the rating of a new part is correct.

Not doing so may result in malfunction or burning.

•Before touching a Unit, be sure to first touch a grounded metallic object in order

to discharge any static built-up. Not doing so may result in malfunction or dam-

age.