110 AC servo systems

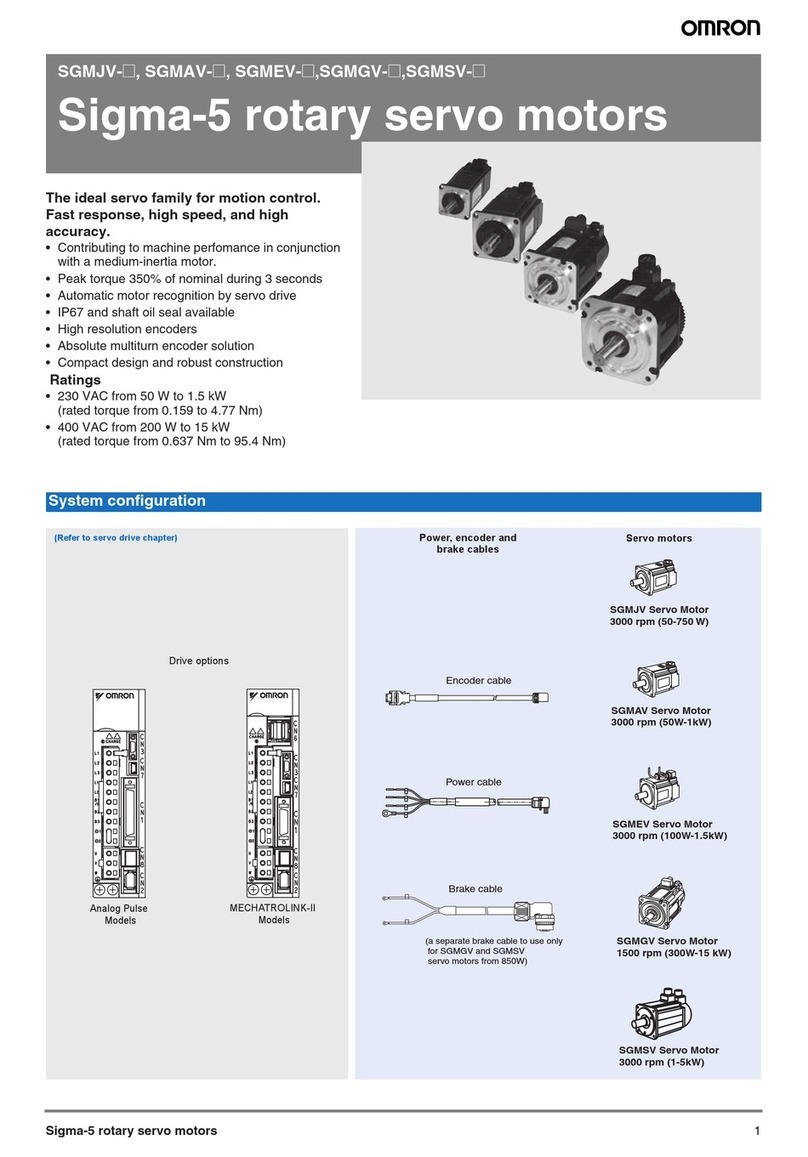

Servo motors 3000 r/min (50 - 5000 W)

Symbol Specifications Servo motor model Compatible servo drives B

Voltage Encoder and design Rated torque Capacity G5 MECHATROLINK-II G5 Analog/Pulse

A

230 V (50 - 750 W)

230 V (1000 - 1500 W)

400 V (750 - 5000 W)

230 V Incremental encoder

(20 bit)

Straight shaft with key

and tap

Without

brake

0.16 Nm 50 W R88M-K05030H-S2 R88D-KN01H-ML2 R88D-KT01H

0.32 Nm 100 W R88M-K10030H-S2 R88D-KN01H-ML2 R88D-KT01H

0.64 Nm 200 W R88M-K20030H-S2 R88D-KN02H-ML2 R88D-KT02H

1.3 Nm 400 W R88M-K40030H-S2 R88D-KN04H-ML2 R88D-KT04H

2.4 Nm 750 W R88M-K75030H-S2 R88D-KN08H-ML2 R88D-KT08H

3.18 Nm 1000 W R88M-K1K030H-S2 R88D-KN15H-ML2 R88D-KT15H

4.77 Nm 1500 W R88M-K1K530H-S2 R88D-KN15H-ML2 R88D-KT15H

With

brake

0.16 Nm 50 W R88M-K05030H-BS2 R88D-KN01H-ML2 R88D-KT01H

0.32 Nm 100 W R88M-K10030H-BS2 R88D-KN01H-ML2 R88D-KT01H

0.64 Nm 200 W R88M-K20030H-BS2 R88D-KN02H-ML2 R88D-KT02H

1.3 Nm 400 W R88M-K40030H-BS2 R88D-KN04H-ML2 R88D-KT04H

2.4 Nm 750 W R88M-K75030H-BS2 R88D-KN08H-ML2 R88D-KT08H

3.18 Nm 1000 W R88M-K1K030H-BS2 R88D-KN15H-ML2 R88D-KT15H

4.77 Nm 1500 W R88M-K1K530H-BS2 R88D-KN15H-ML2 R88D-KT15H

Absolute encoder

(17 bit)

Straight shaft with key

and tap

Without

brake

0.16 Nm 50 W R88M-K05030T-S2 R88D-KN01H-ML2 R88D-KT01H

0.32 Nm 100 W R88M-K10030T-S2 R88D-KN01H-ML2 R88D-KT01H

0.64 Nm 200 W R88M-K20030T-S2 R88D-KN02H-ML2 R88D-KT02H

1.3 Nm 400 W R88M-K40030T-S2 R88D-KN04H-ML2 R88D-KT04H

2.4 Nm 750 W R88M-K75030T-S2 R88D-KN08H-ML2 R88D-KT08H

3.18 Nm 1000 W R88M-K1K030T-S2 R88D-KN15H-ML2 R88D-KT15H

4.77 Nm 1500 W R88M-K1K530T-S2 R88D-KN15H-ML2 R88D-KT15H

With

brake

0.16 Nm 50 W R88M-K05030T-BS2 R88D-KN01H-ML2 R88D-KT01H

0.32 Nm 100 W R88M-K10030T-BS2 R88D-KN01H-ML2 R88D-KT01H

0.64 Nm 200 W R88M-K20030T-BS2 R88D-KN02H-ML2 R88D-KT02H

1.3 Nm 400 W R88M-K40030T-BS2 R88D-KN04H-ML2 R88D-KT04H

2.4 Nm 750 W R88M-K75030T-BS2 R88D-KN08H-ML2 R88D-KT08H

3.18 Nm 1000 W R88M-K1K030T-BS2 R88D-KN15H-ML2 R88D-KT15H

4.77 Nm 1500 W R88M-K1K530T-BS2 R88D-KN15H-ML2 R88D-KT15H

400 V Incremental encoder

(20 bit)

Straight shaft with key

and tap

Without

brake

2.39 Nm 750 W R88M-K75030F-S2 R88D-KN10F-ML2 R88D-KT10F

3.18 Nm 1000 W R88M-K1K030F-S2 R88D-KN15F-ML2 R88D-KT15F

4.77 Nm 1500 W R88M-K1K530F-S2 R88D-KN15F-ML2 R88D-KT15F

6.37 Nm 2000 W R88M-K2K030F-S2 R88D-KN20F-ML2 R88D-KT20F

9.55 Nm 3000 W R88M-K3K030F-S2 R88D-KN30F-ML2 R88D-KT30F

12.7 Nm 4000 W R88M-K4K030F-S2 R88D-KN50F-ML2 R88D-KT50F

15.9 Nm 5000 W R88M-K5K030F-S2 R88D-KN50F-ML2 R88D-KT50F

With

brake

2.39 Nm 750 W R88M-K75030F-BS2 R88D-KN10F-ML2 R88D-KT10F

3.18 Nm 1000 W R88M-K1K030F-BS2 R88D-KN15F-ML2 R88D-KT15F

4.77 Nm 1500 W R88M-K1K530F-BS2 R88D-KN15F-ML2 R88D-KT15F

6.37 Nm 2000 W R88M-K2K030F-BS2 R88D-KN20F-ML2 R88D-KT20F

9.55 Nm 3000 W R88M-K3K030F-BS2 R88D-KN30F-ML2 R88D-KT30F

12.7 Nm 4000 W R88M-K4K030F-BS2 R88D-KN50F-ML2 R88D-KT50F

15.9 Nm 5000 W R88M-K5K030F-BS2 R88D-KN50F-ML2 R88D-KT50F

Absolute encoder

(17 bit)

Straight shaft with key

and tap

Without

brake

2.39 Nm 750 W R88M-K75030C-S2 R88D-KN10F-ML2 R88D-KT10F

3.18 Nm 1000 W R88M-K1K030C-S2 R88D-KN15F-ML2 R88D-KT15F

4.77 Nm 1500 W R88M-K1K530C-S2 R88D-KN15F-ML2 R88D-KT15F

6.37 Nm 2000 W R88M-K2K030C-S2 R88D-KN20F-ML2 R88D-KT20F

9.55 Nm 3000 W R88M-K3K030C-S2 R88D-KN30F-ML2 R88D-KT30F

12.7 Nm 4000 W R88M-K4K030C-S2 R88D-KN50F-ML2 R88D-KT50F

15.9 Nm 5000 W R88M-K5K030C-S2 R88D-KN50F-ML2 R88D-KT50F

With

brake

2.39 Nm 750 W R88M-K75030C-BS2 R88D-KN10F-ML2 R88D-KT10F

3.18 Nm 1000 W R88M-K1K030C-BS2 R88D-KN15F-ML2 R88D-KT15F

4.77 Nm 1500 W R88M-K1K530C-BS2 R88D-KN15F-ML2 R88D-KT15F

6.37 Nm 2000 W R88M-K2K030C-BS2 R88D-KN20F-ML2 R88D-KT20F

9.55 Nm 3000 W R88M-K3K030C-BS2 R88D-KN30F-ML2 R88D-KT30F

12.7 Nm 4000 W R88M-K4K030C-BS2 R88D-KN50F-ML2 R88D-KT50F

15.9 Nm 5000 W R88M-K5K030C-BS2 R88D-KN50F-ML2 R88D-KT50F