E6F-C Incremental 60-mm-dia. Rotary Encoder 5

Operation and Installation

■Precautions

•Do not impose voltages exceeding the rated voltage on the E6F-C,

otherwise the E6F-C may be damaged.

•Be sure that the wiring of the E6F-C, including the polarity, is cor-

rect. The E6F-C may be damaged if wired incorrectly.

•Do not short the load of the E6F-C, otherwise the E6F-C may be

damaged.

•Turn OFF the E6F-C while wiring. Wiring while the power supply is

turned ON could damage the output circuit if the output cable

touches the power supply.

•Do not wire power lines or high-tension lines along with the power

supply lines of the E6F-C, otherwise the E6F-C may be damaged

or malfunction.

■Application

Mounting

Mounting Procedure

1. Insert the shaft into the Coupling.

Do not secure the Coupling and the shaft with screws at this

stage.

2. Secure the E6F-C.

Refer to the following table for the maximum insertion lengths of

the shaft into the Coupling.

3. Secure the Coupling.

4. Connect the power and I/O lines.

Turn OFF the E6F-C when connecting the lines.

5. Turn ON the E6F-C and check the output.

Mounting Information

•Be careful not to allow water, oil, or other substances to be sprayed

on the E6F-C.

•The E6F-C consists of high-precision components. Handle the

E6F-C with utmost care and do not drop it, otherwise malfunction-

ing may result.

•When the E6F-C is to be used in reversing, pay utmost attention to

the mounting direction of the E6F-C, and to the direction of incre-

ment and decrement rotation.

•To match phase Z of the E6F-C to the origin of the device to be

connected to the E6F-C, confirm the phase-Z output when con-

necting the device.

•Do not impose an excessive load on the shaft when the shaft is

connected to a gear.

•If the E6F-C is mounted with screws, the tightening torque must not

exceed 0.49 N

¼

m.

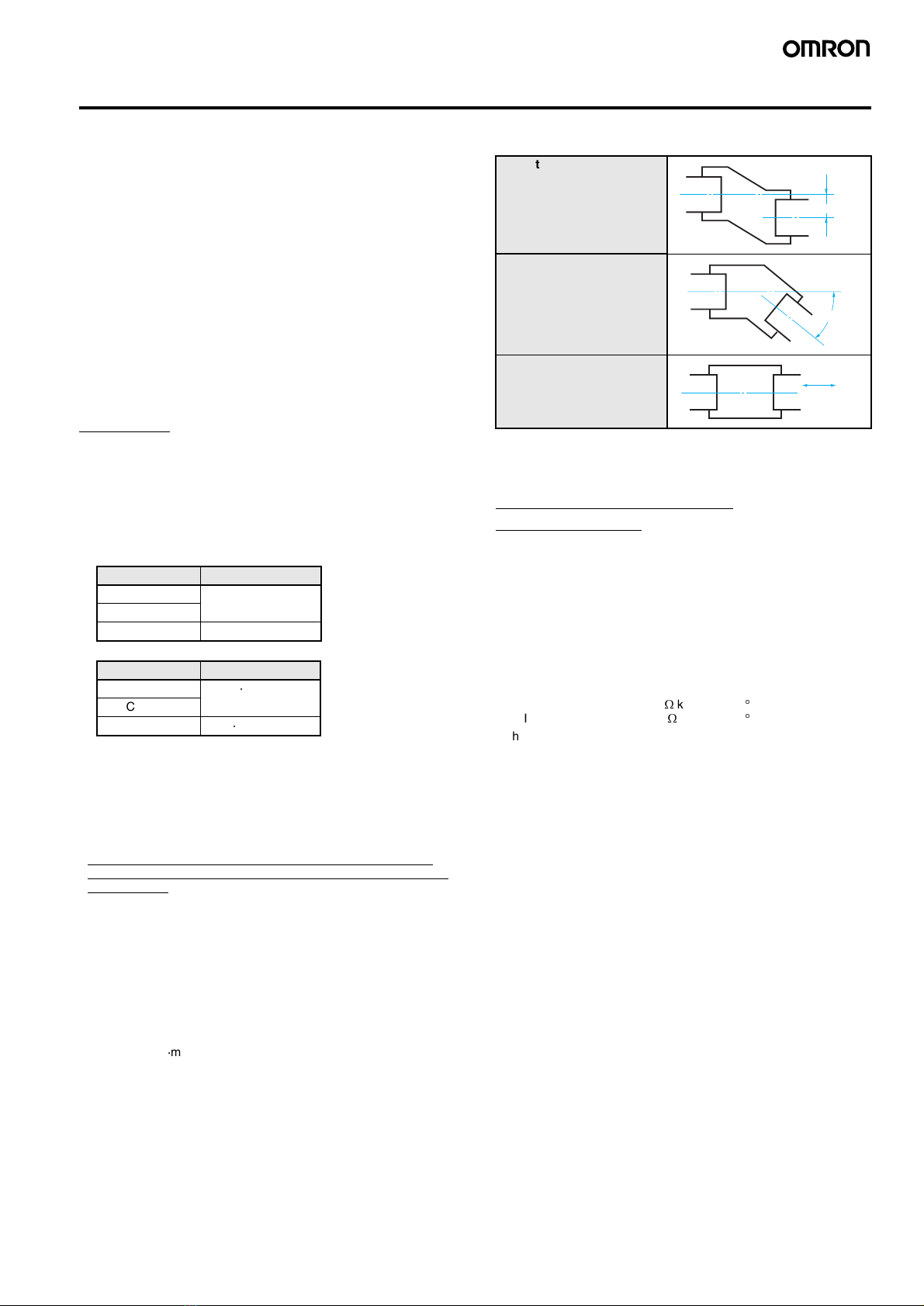

•When using a Coupling, mount within the following tolerances.

•If the eccentricity or declination value exceeds the tolerance, an

excessive load on the shaft may damage the E6F-C or shorten the

life of the E6F-C.

Wiring: Cable Extension

Characteristics

•When the cable length is extended, the output waveform startup

time is lengthened and it affects the phase difference characteris-

tics of phases A and B. Conditions will change according to fre-

quency, noise, and other factors. As a guideline, use a cable length

of 10 m or less. If extending the cable length beyond 10 m, use the

line driver output or complementary output.

(Line driver output length: 100 m max; complementary output

length: 30 m max.)

Recommended Cable:

Conductor cross-sectional area: 0.2 mm2

Spiral shield

Conductor resistance: 92

W

/km max. (20

C)

Insulation resistance: 5 M

W

/km min. (20

C)

•The output waveform startup time changes not only according to

the length of the cable, but also according to the load resistance

and the cable type.

•Extending the cable length not only changes the startup time, but

also increases the output residual voltage.

Coupling Insertion length

E69-C10B 7.1 mm

E69-C610B

E69-C10M 10.5 mm

Coupling Tightening torque

E69-C10B 0.44 N

¼

m

E69-C610B

E69-C10M 3.5 N

¼

m

Eccentricity tolerance

Declination tolerance

Displacement tolerance in

the shaft direction

0.15 mm max.

2°max.

0.05 mm max.