CONTENTS

Sections in this Manual ........................................................................................... 3

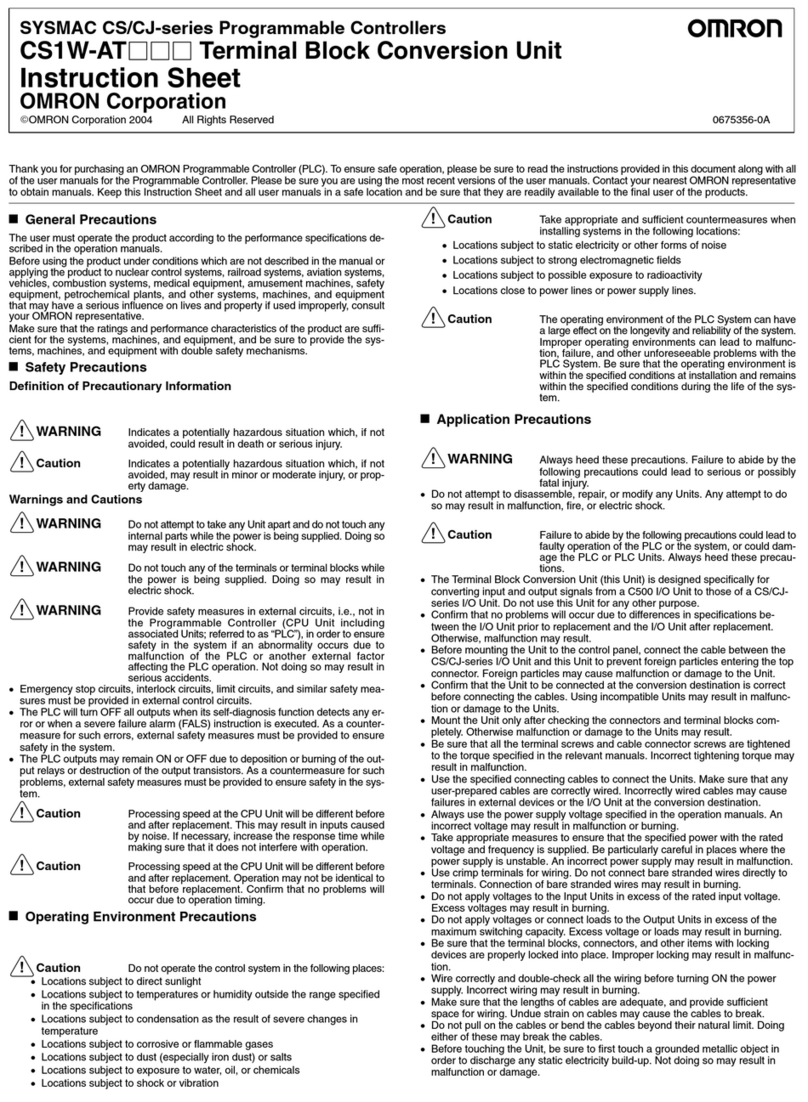

Precautions .............................................................................................................. 5

Related Manuals....................................................................................................... 6

Terms and Definitions.............................................................................................. 7

Revision History....................................................................................................... 8

Section 1 About This Guide

1-1 Introduction ............................................................................................................................1-2

1-1-1 Intended Audience ......................................................................................................................1-2

Section 2 Target Device and Device Configuration

2-1 Device Configuration.............................................................................................................2-2

Section 3 Serial Encoder Connection Procedures

3-1 Work Flow...............................................................................................................................3-2

3-2 Controller Setting Preparations............................................................................................3-3

3-2-1 Creation of a New Project ...........................................................................................................3-3

3-2-2 Controller Initial Setting ...............................................................................................................3-4

3-3 Serial Encoder Wiring............................................................................................................3-6

3-4 Various Controller Settings and Checking Operation........................................................3-7

Section 4 Serial Encoder Status and Error Information

4-1 BiSS-C Encoder Error Information.......................................................................................4-2

4-2 EnDAT2.2 Encoder Status and Error Information...............................................................4-3

4-3 1S Motor Encoder Status and Error Information ................................................................4-4

CONTENTS

4Startup Guide for Serial Encoder BiSS-C/EnDAT 2.1/2.2/1S Motor (O051)