2

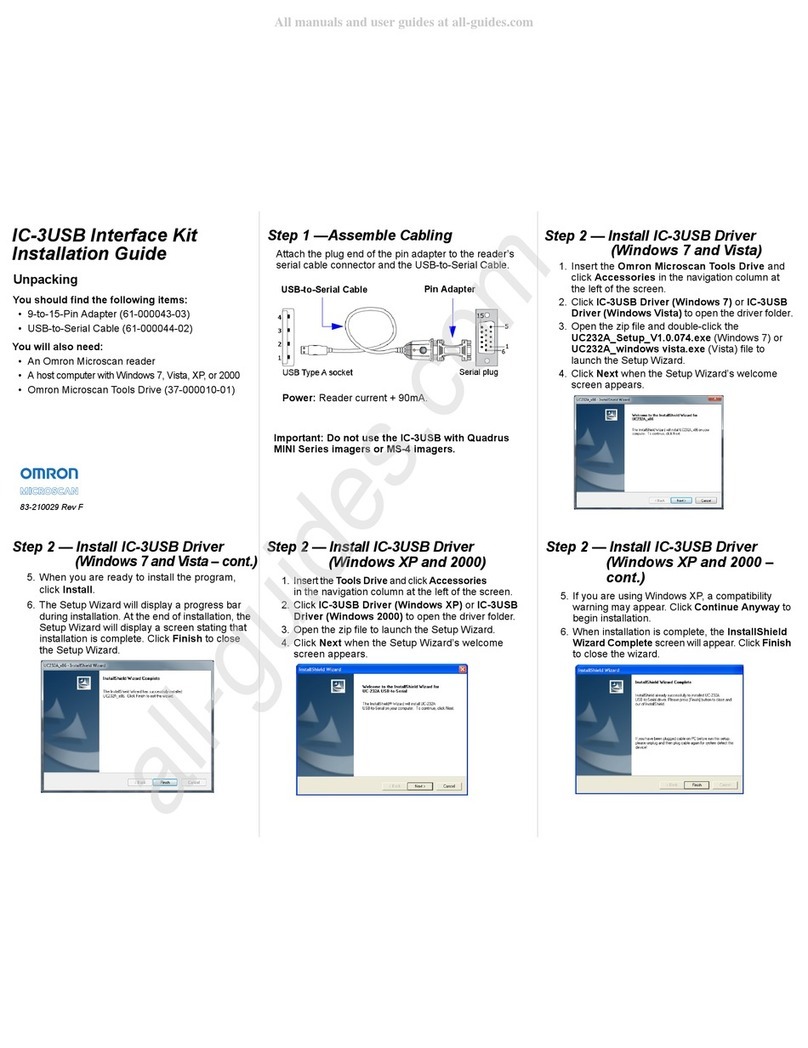

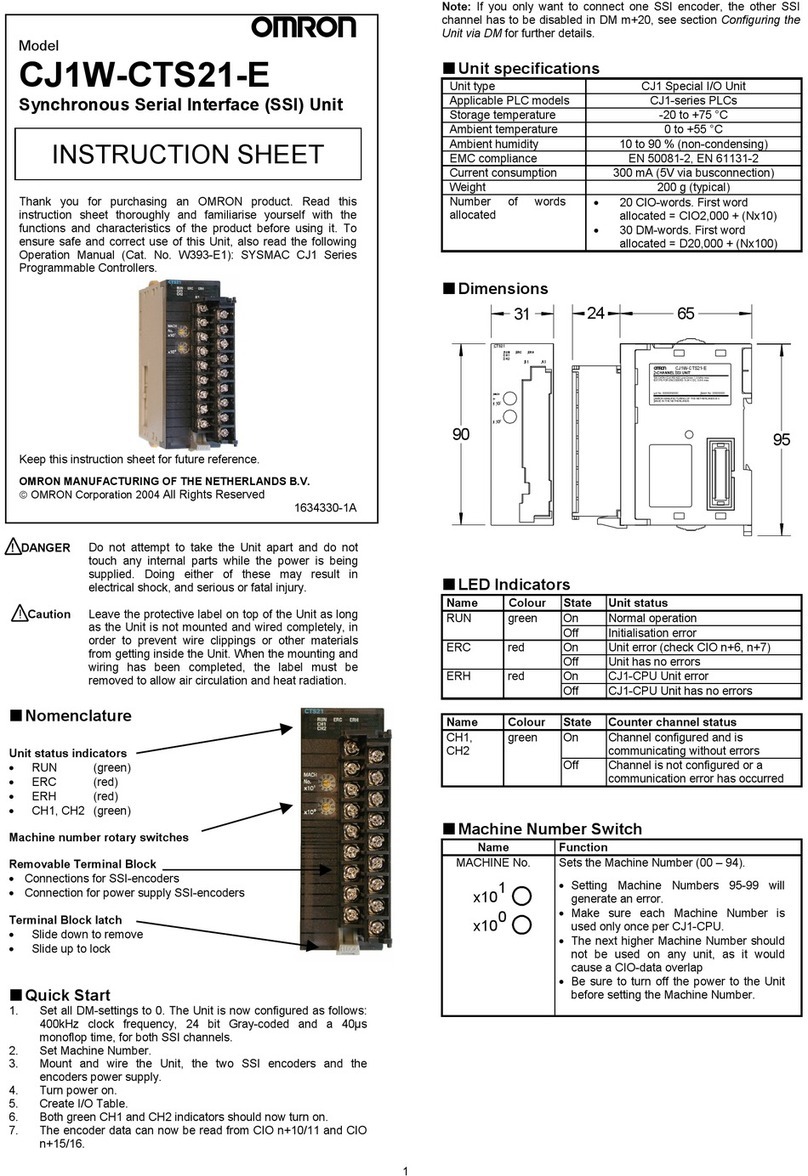

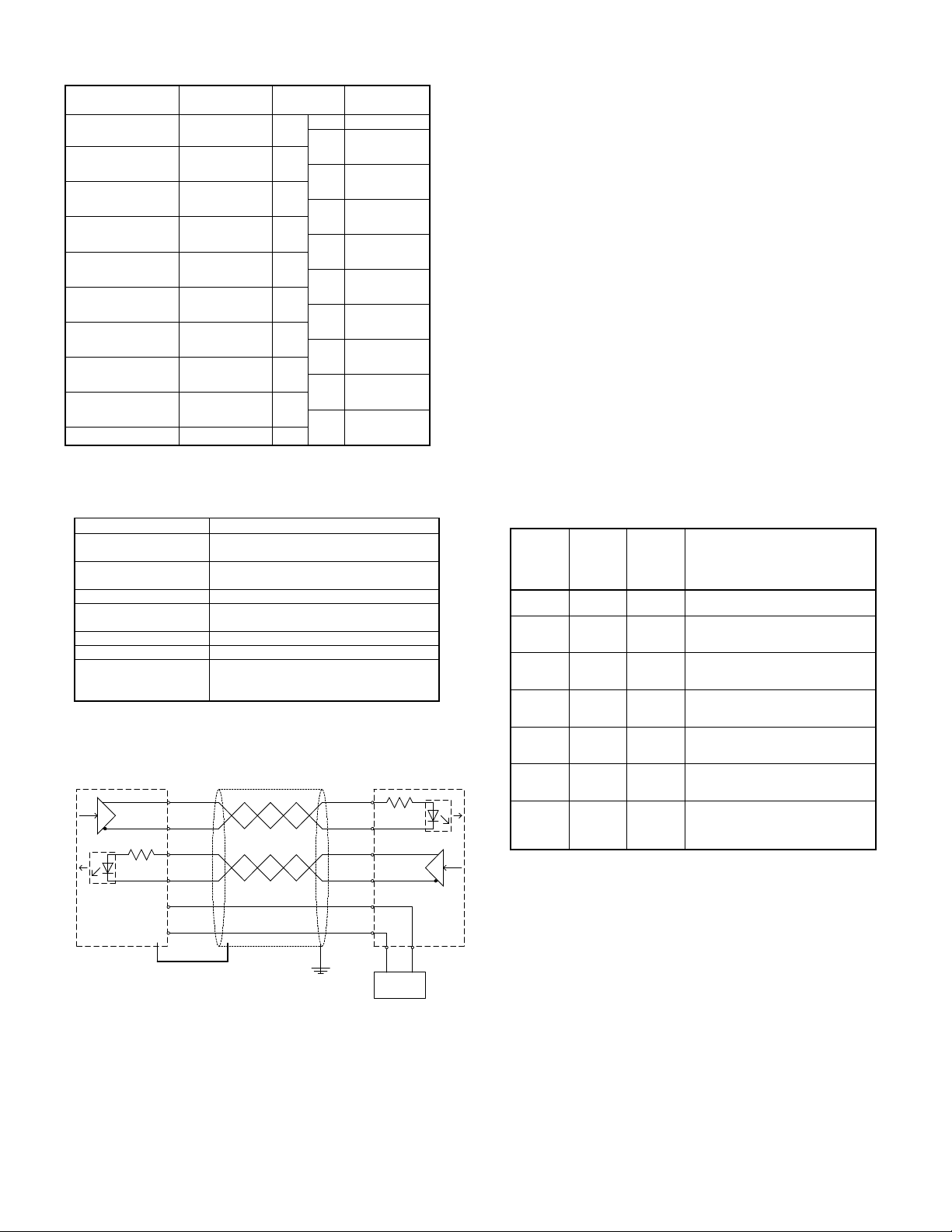

Terminal Block layout

Use the following table to make connections directly to the screw

terminals block:

Item Description

Row B Terminal

no. Description

Row A

SSI DATA CH1 DATA1 - B1

A1 DATA1 +

SSI Clock CH1 CLOCK1 - B2 A2 CLOCK1 +

SSI Power Supply

OUT CH1 0V_ENC_PS¹ B3 A3 +_ENC_PS

2

N.C. B4 A4 N.C.

SSI DATA CH2 DATA2 - B5 A5 DATA2 +

SSI Clock CH2 CLOCK2 - B6 A6 CLOCK2 +

SSI Power Supply

OUT CH2 0V_ENC_PS¹ B7 A7 +_ENC_PS

2

N.C. B8 A8 N.C.

Encoder Power

Supply Input 0V_ENC_PS¹ B9 A9 +_ENC_PS

2

(

1

)(

2

): All these pins are internally connected.

SSI Communication

Item Specification

CLK lines Non-isolated differential line driver,

RS422 compliant

DATA lines Electrically isolated differential line

receiver, RS422 compliant

Number of data-bits 9 to 31 (default: 24)

Value coding Gray/Binary/Tannenbaum/Raw

(default Gray)

Clock frequency 100kHz to 1.5 MHz (default 400 kHz)

Monoflop time 10µs to 99,990 µs (default: 40 µs)

Sample rate Approx. 2500 Samples/sec with 2

encoders connected

(with default settings)

Default: All DM-settings are 0000

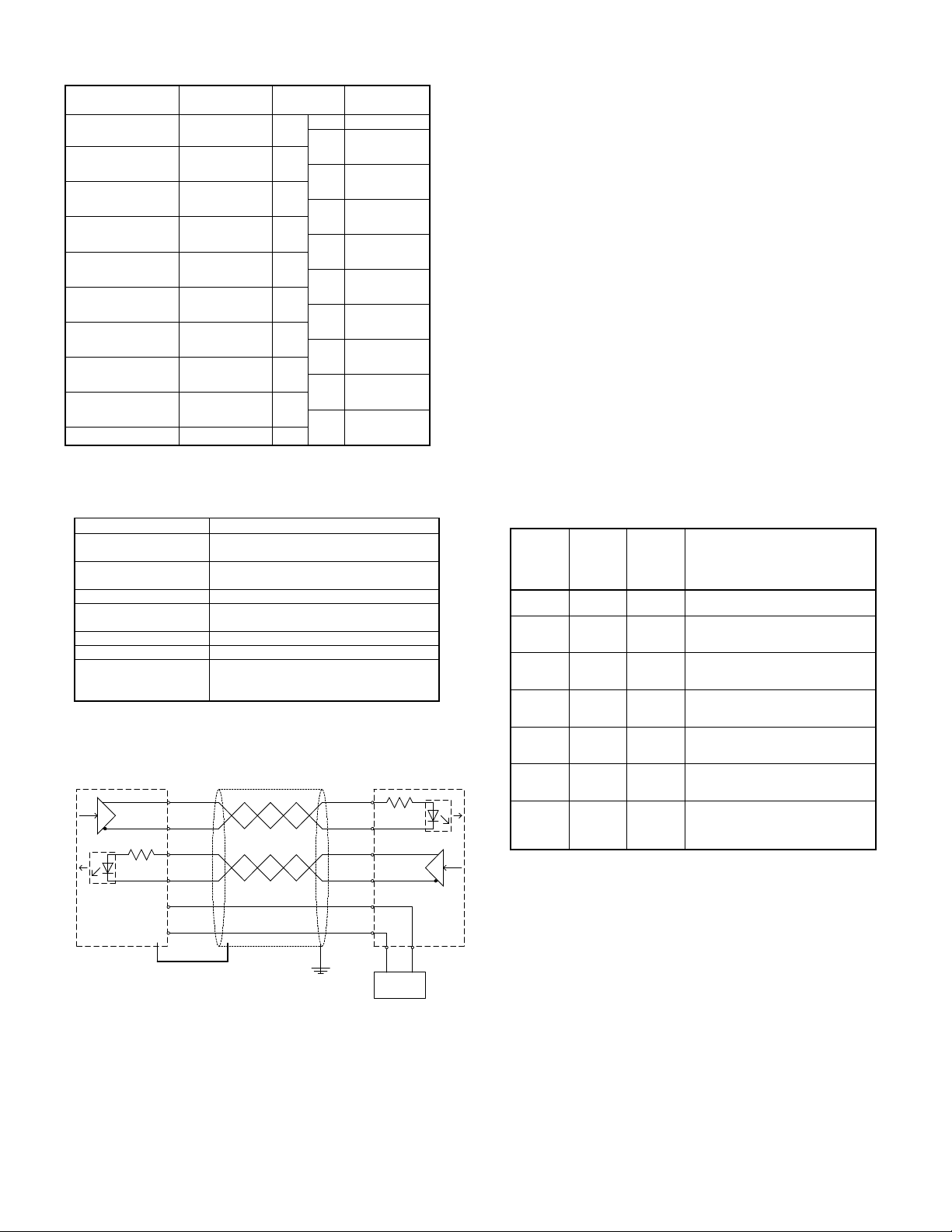

SSI Circuitry

DATA+

DATA-

CLOCK+

CLOCK-

+_ENC_PS

0V_ENC_PS

Shielded Twisted-pair Cable

SSI ENCODER CJ1W-CTS21-E

B3

A3

B2

A2

B1

A1

ENCODER

PS

B9 A9

+

-

RS422

+

-

RS422

Notes:

•Electrical isolation is provided for each data input line.

Electrical isolation is not provided for the outgoing clock lines.

The encoder power supply can be connected to the unit’s

connector.

•The power supply should match the encoder’s specifications.

•Use shielded twisted pair, 2×2×0.25mm

2

(+ optional

2×0.5mm

2

for PS).

•The shield must be connected to the SSI encoder and to the

frame-ground near the PLC-system.

•Recommended maximum cable length by selected clock

frequency: 100 kHz: < 400 m

300 kHz: < 100 m

200 kHz: < 200 m

400 kHz: < 50 m.

Communication Errors

During normal operation, the SSI Unit can detect three kinds of

communication errors (see section Error Processing). At the

occurrence of a communication error on channel 1(2):

•the corresponding error code is set in device variables

*_ErrCode1 and *_ErrCode2

•the corresponding error code is stored inside the SSI Unit

•the Global Error device variable *_GlblErr is turned ON

•the ERC LED indicator is turned ON

•the corresponding CH1(2) LED indicator is turned OFF

This status will remain, even if during the next SSI-communication no

error is detected by the SSI Unit. In this case only the valid SSI data

received device variable *_Ch1(2)_ValidDatRcvSta will be turned ON

indicating that for the current SSI data, no communication error was

detected.

To clear the above error status, the clear all errors device variable

*_ClrAllErr has to be turned ON.

The following table describes the possible statuses of the SSI Unit

after proper initialisation:

ERC

LED /

Global

error bit

CH

LED New

Valid

SSI data

received

bit

Status

Off On On The channel

SSI data can be

used; no error has occurred.

Off On Off No new channel SSI data has

been received since last cyclic

refresh; no error has occurred.

Off Off Off Channel

is not configured for SSI

communication (see Configuration

Device Variables).

On Off On The channel

SSI data can be

used; a communication error has

occurred earlier *.

On Off Off The channel SSI data cannot be

used; a communication error has

occurred *.

On On On The channel

SSI data can be

used; a non-communication error

has occurred *.

On On Off No new channel

SSI data has

been received since last cyclic

refresh; a non-communication error

has occurred *.

* See Error Processing section for countermeasures.

Noise Prevention

The symptoms of picking up noise are random jumps in the SSI data

values read (*_Ch1_SSIDat, *_Ch2_SSIDat). For applications that

expect a continuous change of SSI data values, the user program

can identify noise by detecting an unexpected large change in the

SSI data values or data values outside the expected range.

The best way to prevent noise is by proper wiring the unit as

described in the SSI Circuitry section.

An alternative could be to use an SSI encoder equipped with parity.