TABLE OF CONTENTS

vii

PRECAUTIONS xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Intended Audience xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Conformance to EC Directives xvii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1

Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 Features of the DeviceNet Interface Unit 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 DeviceNet Functions 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 System Configuration 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 Outline of Configurator 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5 Functions of the DeviceNet (CompoBus/D) Interface Unit 10. . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

Operating Procedures 15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1 Operating Procedures Flowchart 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Simple System Configuration 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3

Network Design 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1 Network Configuration 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Limitations on the Network Configuration 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Sharing the Communications Power Supply 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Grounding the Network 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5 Noise Precautions 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6 Correcting Faulty Operation Caused by Noise 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7 Sharing the Same Power Supply 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4

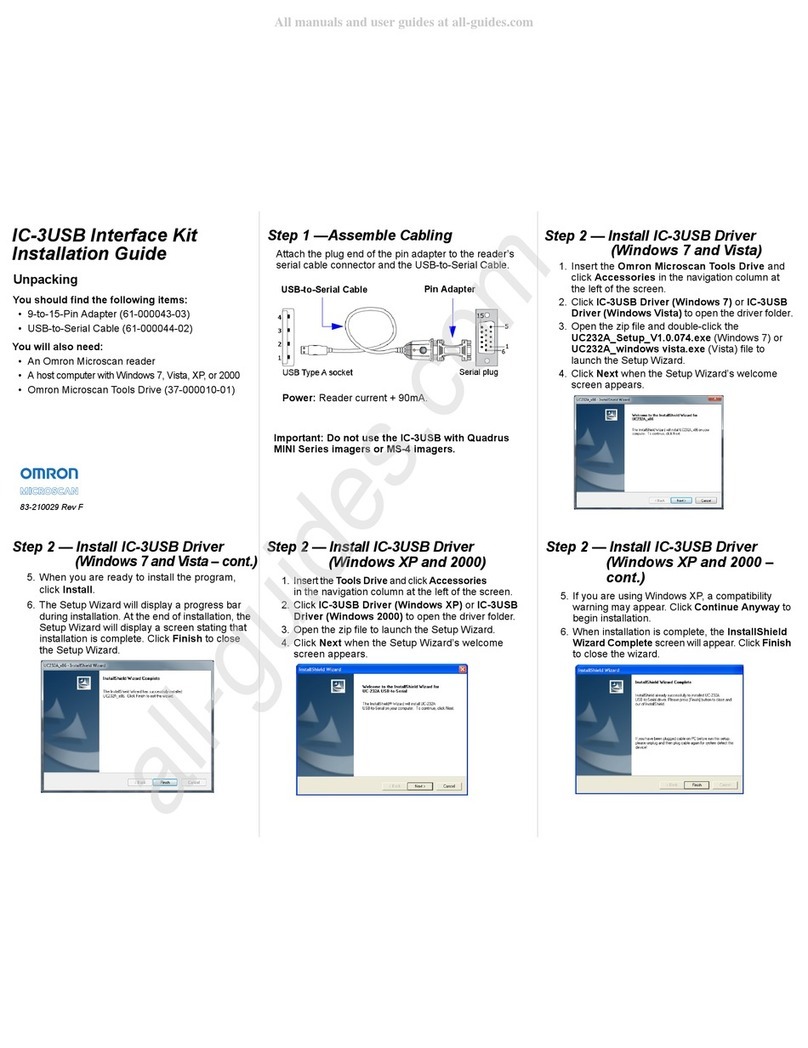

Installation and Network Connection 43. . . . . . . . . . . . . . .

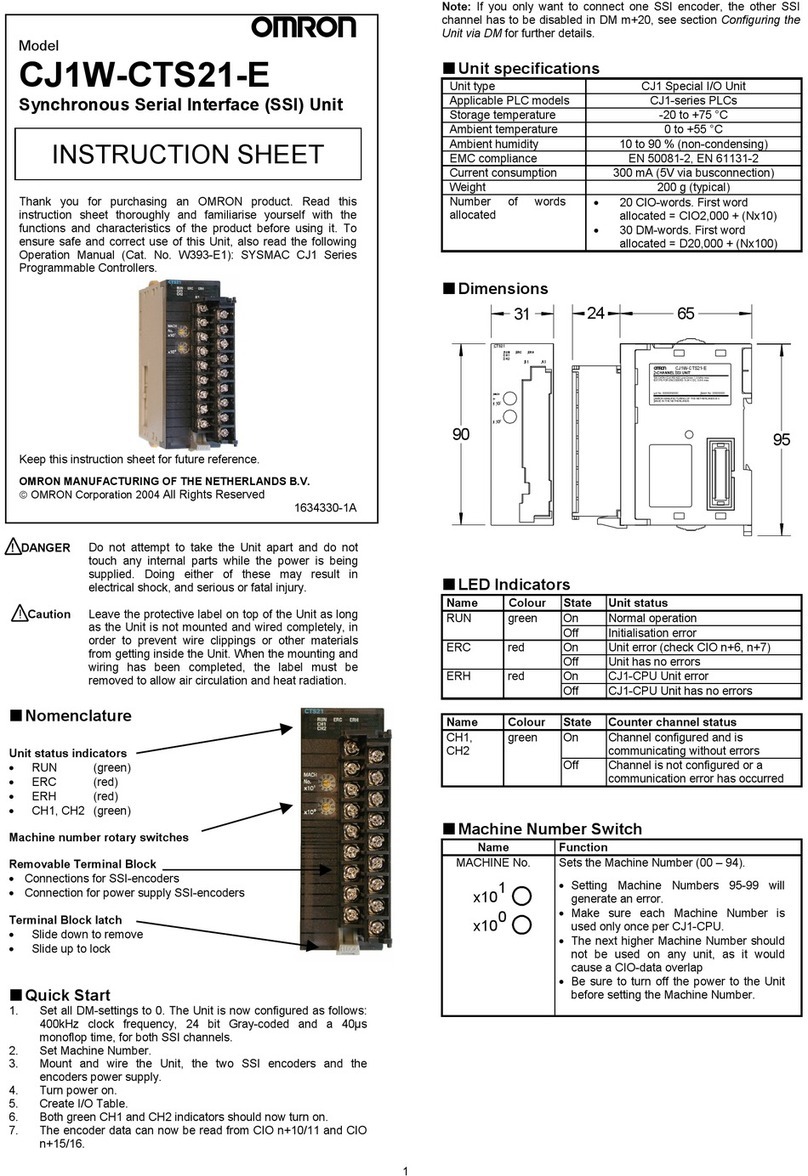

4-1 Components and Their Functions 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Mounting the Unit on the PT 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Connecting to the DeviceNet Network 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5

PT Settings and Operations 51. . . . . . . . . . . . . . . . . . . . . . .

5-1 Installing the System Program 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Structure of the System Menu 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Initializing DeviceNet (CompoBus/D) Memory Switches 57. . . . . . . . . . . . . . . . . . . . . . . .

5-4 Serial Port A Settings 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5 DeviceNet (CompoBus/D) Memory Switch Settings 61. . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-6 Checking the PT Settings 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-7 Checking Communications with the PT 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-8 Checking the System Program Version 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6

Remote I/O Communications 69. . . . . . . . . . . . . . . . . . . . . .

6-1 Overview of Remote I/O Communications 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2 Settings with the NT-series Support Tool 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3 Allocating PT Memory to the Host (Master) 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4 Allocating PT Data to PT Memory 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .