vii

TABLE OF CONTENTS

PRECAUTIONS .........................................................................................xi

1 Intended Audience.....................................................................................................................................xii

2 General Precautions...................................................................................................................................xii

3 Safety Precautions .....................................................................................................................................xii

4 Operating Environment Precautions..........................................................................................................xii

5 Application Precautions............................................................................................................................xiii

6 EC Directives............................................................................................................................................xiv

1 AS-INTERFACE .................................................................................. 1

1-1 Introduction..............................................................................................................................................................2

1-2 Master Functionality.................................................................................................................................................7

1-3 Slave Functionality...................................................................................................................................................8

2 INSTALLATION.................................................................................. 9

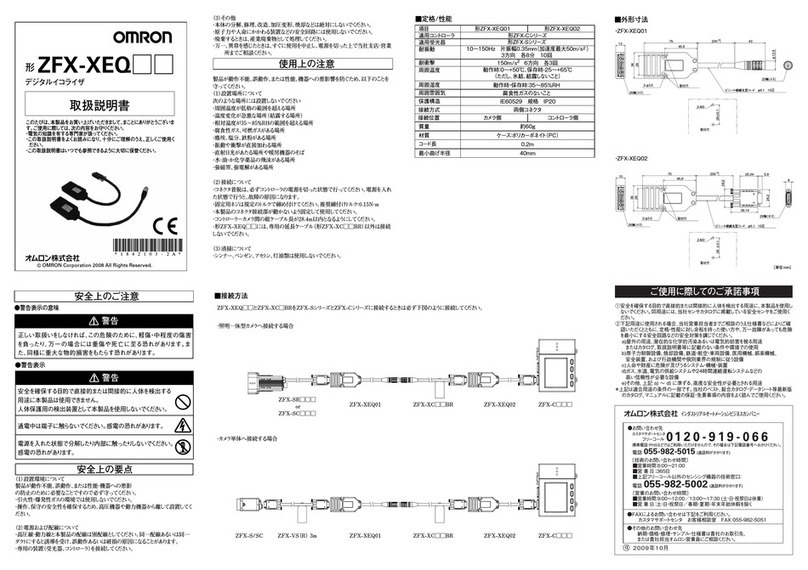

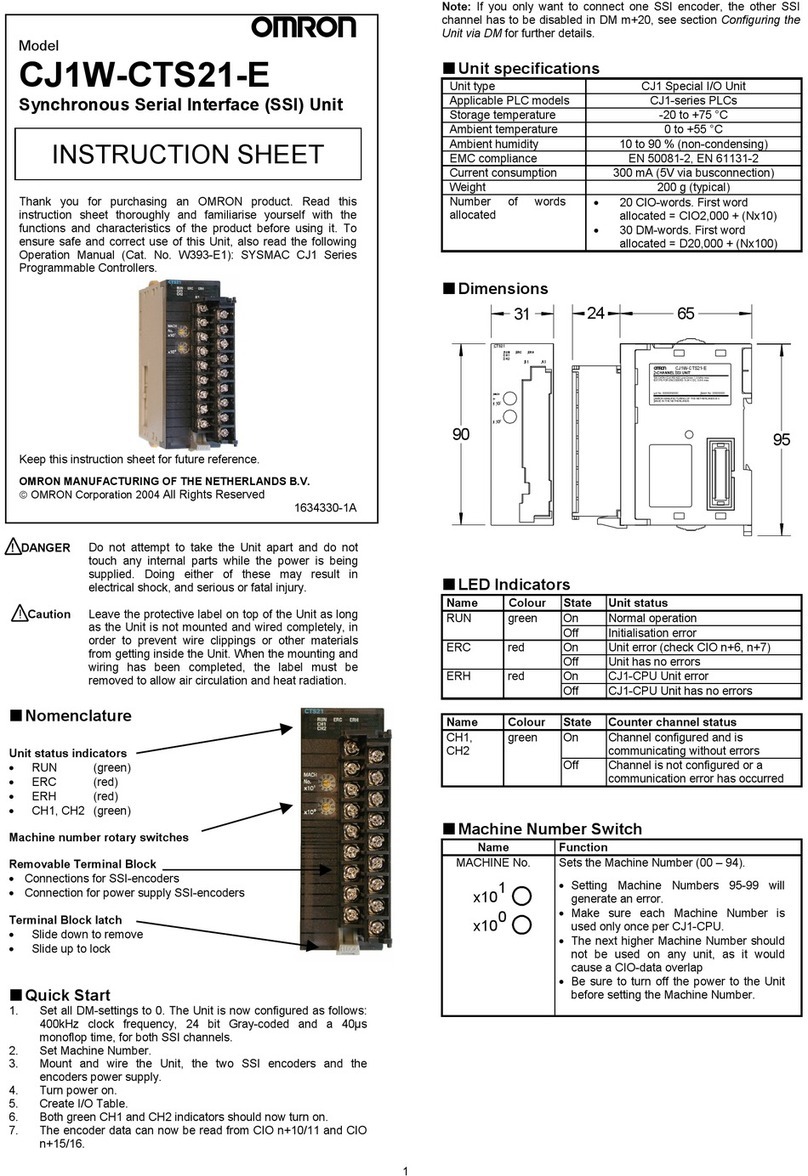

2-1 Physical Layout of the Unit....................................................................................................................................10

2-2 Mounting the CQM1-ARM21................................................................................................................................14

2-3 AS-Interface Network Installation..........................................................................................................................15

3 SPECIFICATIONS AND PERFORMANCE..................................17

3-1 Overall Specifications............................................................................................................................................18

3-2 Dimensions.............................................................................................................................................................19

3-3 Performance ...........................................................................................................................................................19

4 PLC INTERFACE..............................................................................25

4-1 PLC Settings...........................................................................................................................................................26

4-2 Internal Data Structures..........................................................................................................................................27

4-3 Master Operation Modes........................................................................................................................................28

4-4 AS-Interface Standard Modes................................................................................................................................31

4-5 Setup Mode............................................................................................................................................................34

5 SYSTEM CONFIGURATION..........................................................49

5-1 AS-Interface Set-up Methods.................................................................................................................................50

5-2 Bottom-up Method.................................................................................................................................................50

5-3 Top-down Method..................................................................................................................................................51

6 TROUBLESHOOTING AND MAINTENANCE ...........................53

6-1 Error indicators ......................................................................................................................................................54

6-2 Troubleshooting .....................................................................................................................................................54

6-3 Maintenance...........................................................................................................................................................58

7 APPENDICES.....................................................................................59

Appendix A AS-Interface PICS.......................................................................................................................................60

Appendix B AS-Interface Slave Profiles.........................................................................................................................63

Appendix C AS-Interface terminology and abbreviations...............................................................................................64

Index............................................................................................................67

Revision History.........................................................................................69